Preparation method of polyamide inhibitor for drilling liquid

A polyamide and inhibitor technology, applied in the field of preparation of polyamide inhibitors, can solve the problems of limited adsorption capacity, loss of inhibitory effect, etc., and achieve the effects of small influence, good inhibitory effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Add nitrilotriacetic acid and a certain amount of N-methylpyrrolidone into a device with stirring, reflux condenser, thermometer and a device with a nitrogen pipe, and stir at room temperature until the monomer is completely dissolved;

[0025] Start to heat up, and after reaching 80°C, add N,N'-hydroxydiimidazole (ratio of the amount of substance to nitrilotriacetic acid is 3:1), react for 4 hours, bubble nitrogen for several minutes, and then add 4,4 '-diaminodiphenyl ether (the ratio of the amount of substance to nitrilotriacetic acid is 1:1);

[0026] After the system reacted at this temperature for several hours, benzyl alcohol was added, and the reaction was continued for 4 hours to terminate the reaction.

Embodiment 2

[0028] Add nitrilotriacetic acid and a certain amount of N-methylpyrrolidone into the reaction kettle with stirring, reflux condenser device, thermometer and nitrogen pipe, and stir at room temperature until the monomer is completely dissolved;

[0029] Start to heat up, after reaching 80°C, add N,N'-hydroxydiimidazole (ratio of substance to nitrilotriacetic acid is 3:1), react for 3 hours, blow nitrogen for several minutes, and then add ethylenediamine (The ratio of the amount of substance to nitrilotriacetic acid is 1:1);

[0030] After the system reacted at this temperature for several hours, benzyl alcohol was added, and the reaction was continued for 3 hours to terminate the reaction.

Embodiment 3

[0032] Add trimesic acid and a certain amount of N-methylpyrrolidone into the reactor body with stirring, reflux condenser device, thermometer and nitrogen pipe, and stir at normal temperature until the monomer is completely dissolved;

[0033] Start to heat up, and after reaching 80°C, add N,N'-hydroxydiimidazole (the ratio of the amount of trimesic acid to the substance is 3:1), react for 5 hours, and bubble nitrogen for several minutes to remove oxygen in the device , and then add 4,4'-diaminodiphenyl ether (the ratio of the amount of trimellitic acid to the substance is 1:1);

[0034] After the system reacted at this temperature for several hours, benzyl alcohol was added, and the reaction was continued for 5 hours to terminate the reaction.

[0035] Embodiment performance evaluation method

[0036] 1. Polyamide inhibitor rolling recovery test

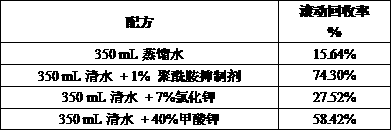

[0037] Get 4 parts of 350mL distilled water, three parts of which add 1% polyamide inhibitor (embodiment 3), 7% commonly used i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com