Inorganic filler modified polyurethane foam material and preparation method thereof

A polyurethane foam and inorganic filler technology, applied in the field of inorganic filler modified polyurethane foam and its preparation, can solve the problems of poor adsorption performance and biocompatibility, achieve controllable expansion ratio, meet the requirements of environmental protection and sustainable development Demand, the effect of simple foaming process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

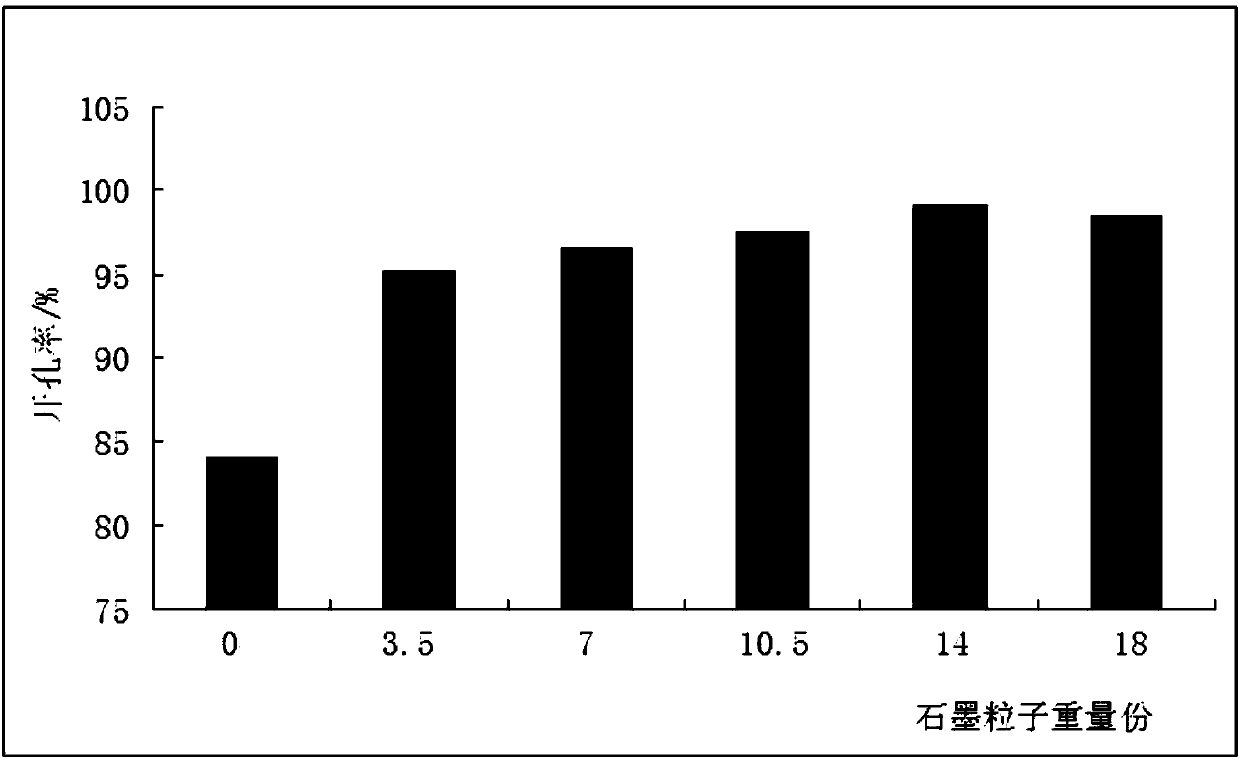

[0022] In the first step, preheat polyether polyol (ALDRICH company, product number 435406) and toluene diisocyanate respectively at a temperature of 35° C. for 1 h; in the second step, mix 100 parts of polyether polyol, 5 parts of deionized water, 0.5 part of triethanolamine, 0.5 part of high-efficiency silicone glycol copolymer, and graphite particles are respectively selected from 0 part (blank comparative example), 3.5 parts (embodiment 1), 10.5 parts (embodiment 2), 18 parts of (embodiment 3), 25 parts of (embodiment 4) and 30 parts of (embodiment 5), above-mentioned raw material is stirred and mixed, and stirring speed is 1000r / min, and stirring time is 1 minute; The above-mentioned mixture of the 3rd step is mixed with Stir 57 parts of toluene diisocyanate and 0.5 parts of triethanolamine at high speed, the stirring speed is 2000r / min, and the stirring time is 3 seconds; the fourth step is pouring into the mold, foaming freely, and standing still for 20-30min at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com