A coil spring-driven wire rope winding mechanism based on pulley group rope arrangement

A technology of winding mechanism and pulley block, which is applied in the direction of clockwork mechanism, hoisting device, portable lifting device, etc., can solve the problems of inconvenient, entangled astronauts, difficult control and other problems for astronauts, and achieve good The effect of space adaptability and reliability, simple structure and compact configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

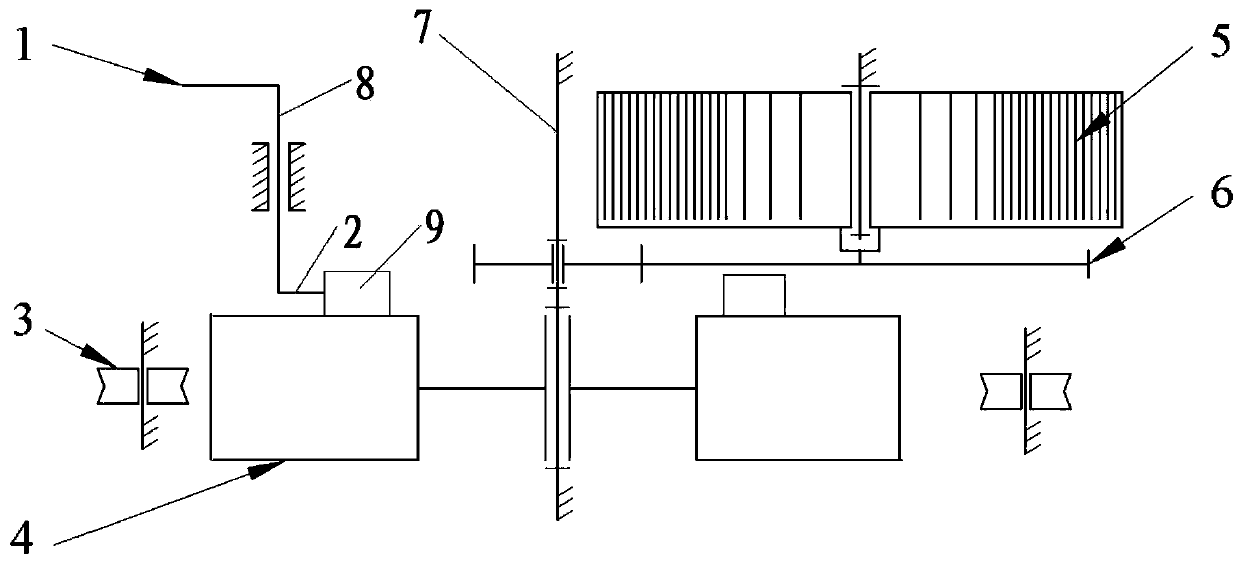

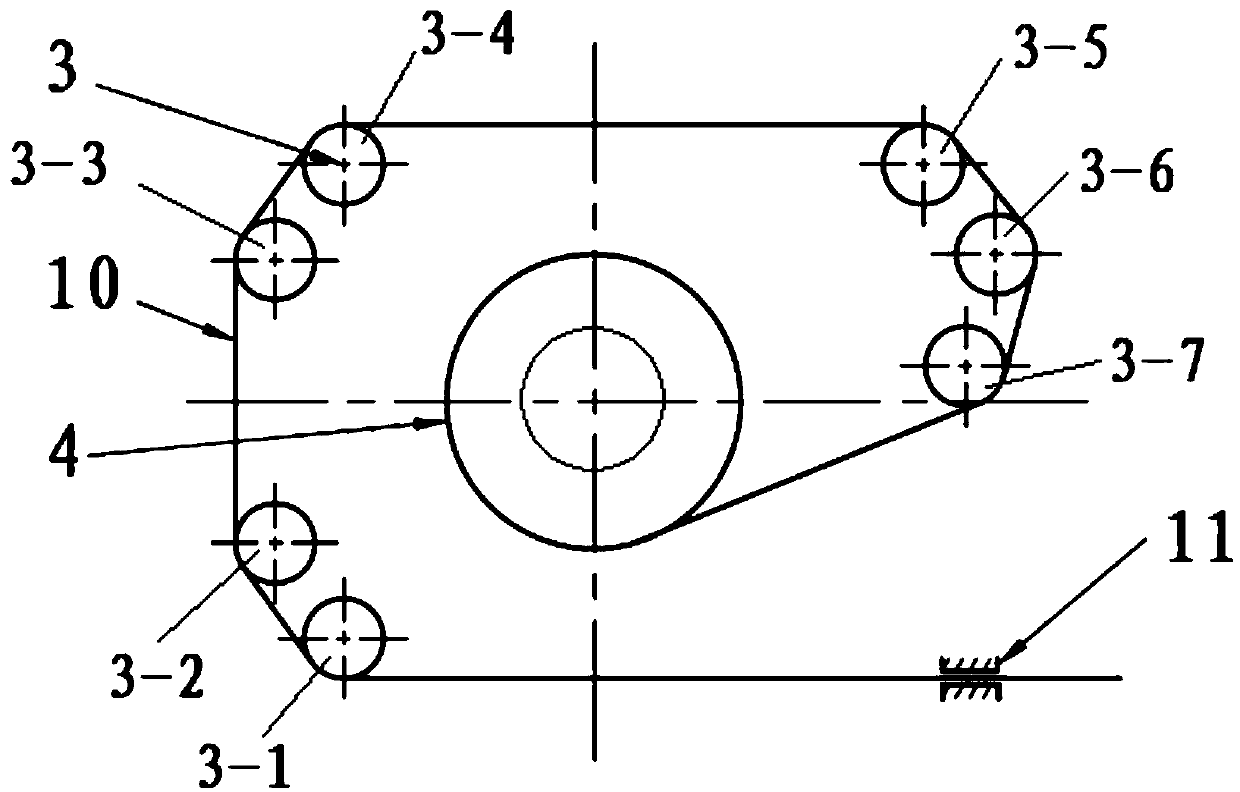

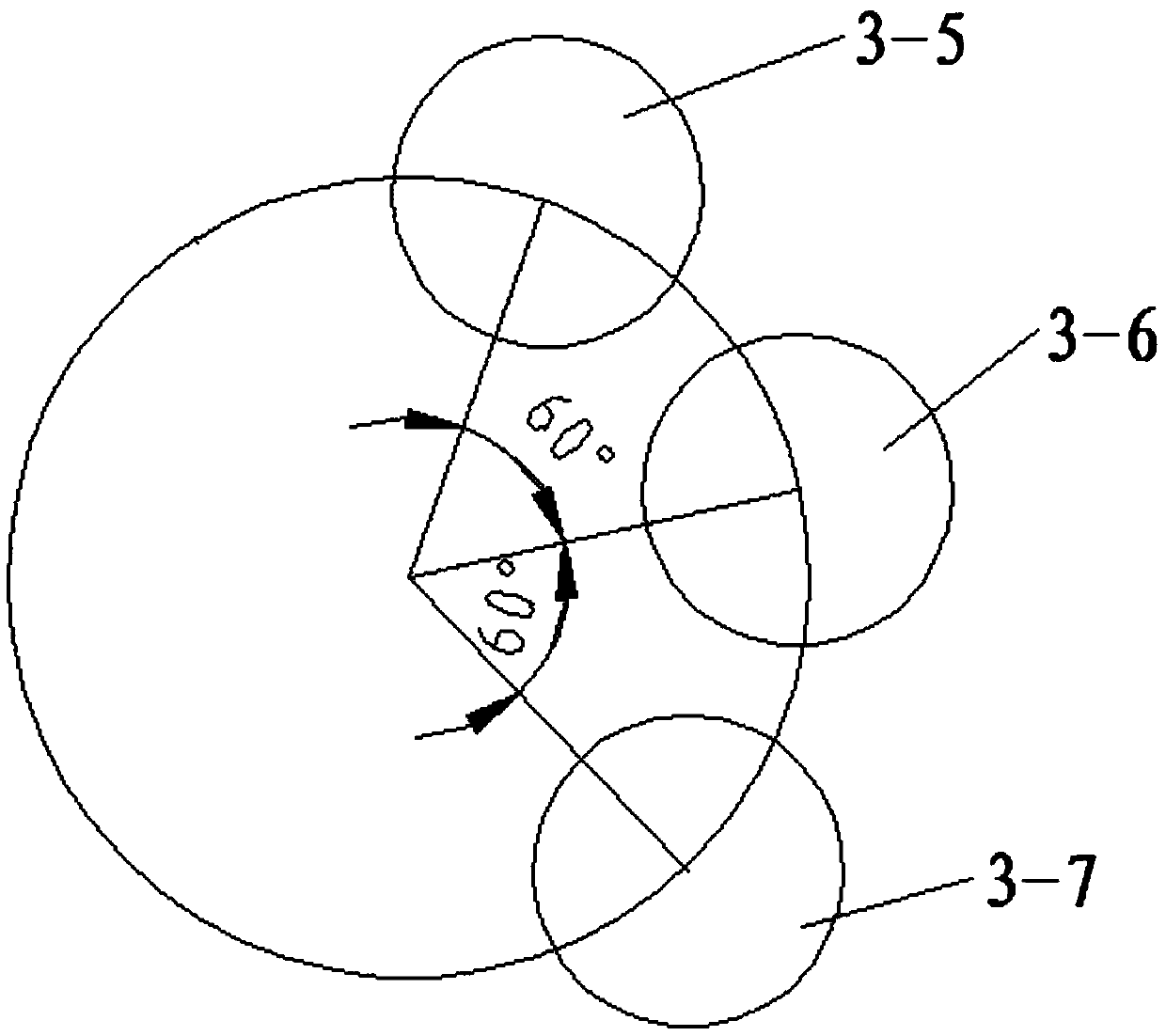

[0027] The present invention uses the contact-type planar scroll spring 5 as the power source, and the contact-type planar scroll spring 5 can obtain more working turns under the condition of occupying the same volume. The scroll spring 5 transmits the rotational driving torque to the reel 4 through a pair of transmission gears 6, thereby driving the reel 4 to rotate and complete the action of winding the wire rope 10. The transmission gear pair 6 reduces the driving torque of the scroll spring 5, and at the same time increases the number of driving turns within the effective driving torque range. The scroll spring 5 is used as the power source, no motor is required to provide a rotating torque, the introduction of cables is avoided, and the convenience and mobility of the astronauts are enhanced.

[0028] The present invention adopts the auxiliary ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com