Automatic disk inserting machine of multi-track lighter barrel

A lighter, multi-track technology, applied in the direction of a single object, transportation and packaging, packaging, etc., can solve the problems such as the collision of the lighter barrel with the ground, the collision of the lighter barrel, scratches, the loss of job population, etc., to save manpower Capital, manpower saving, and accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

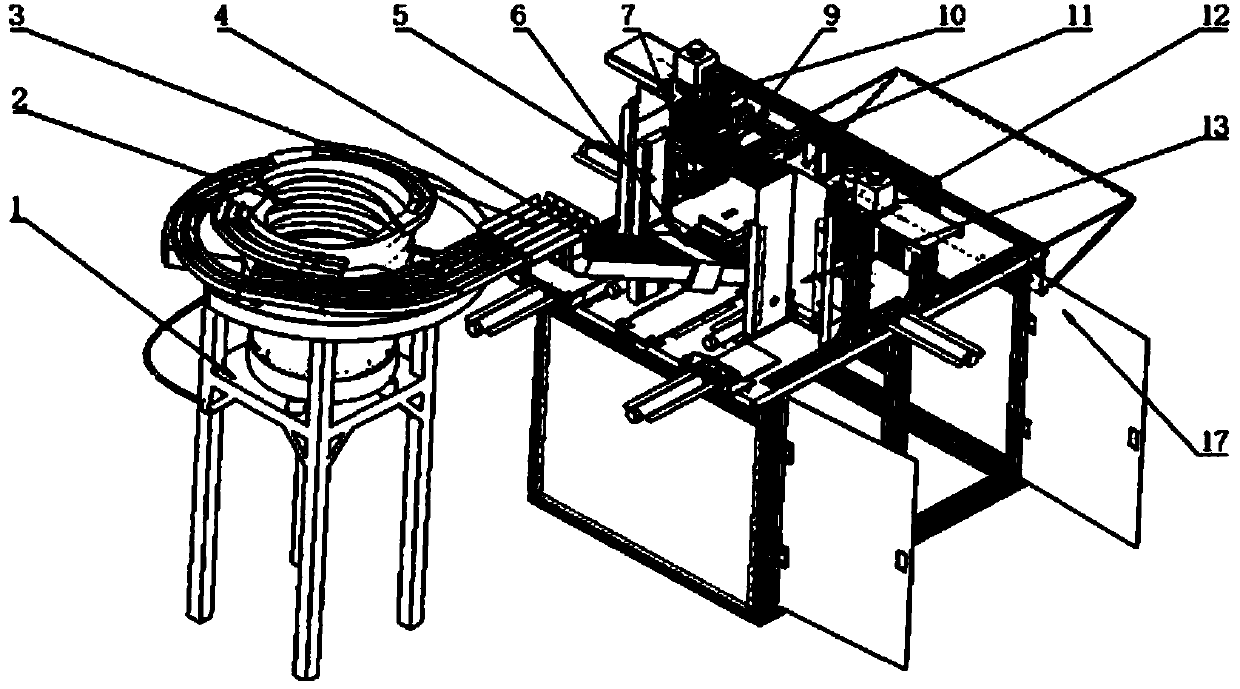

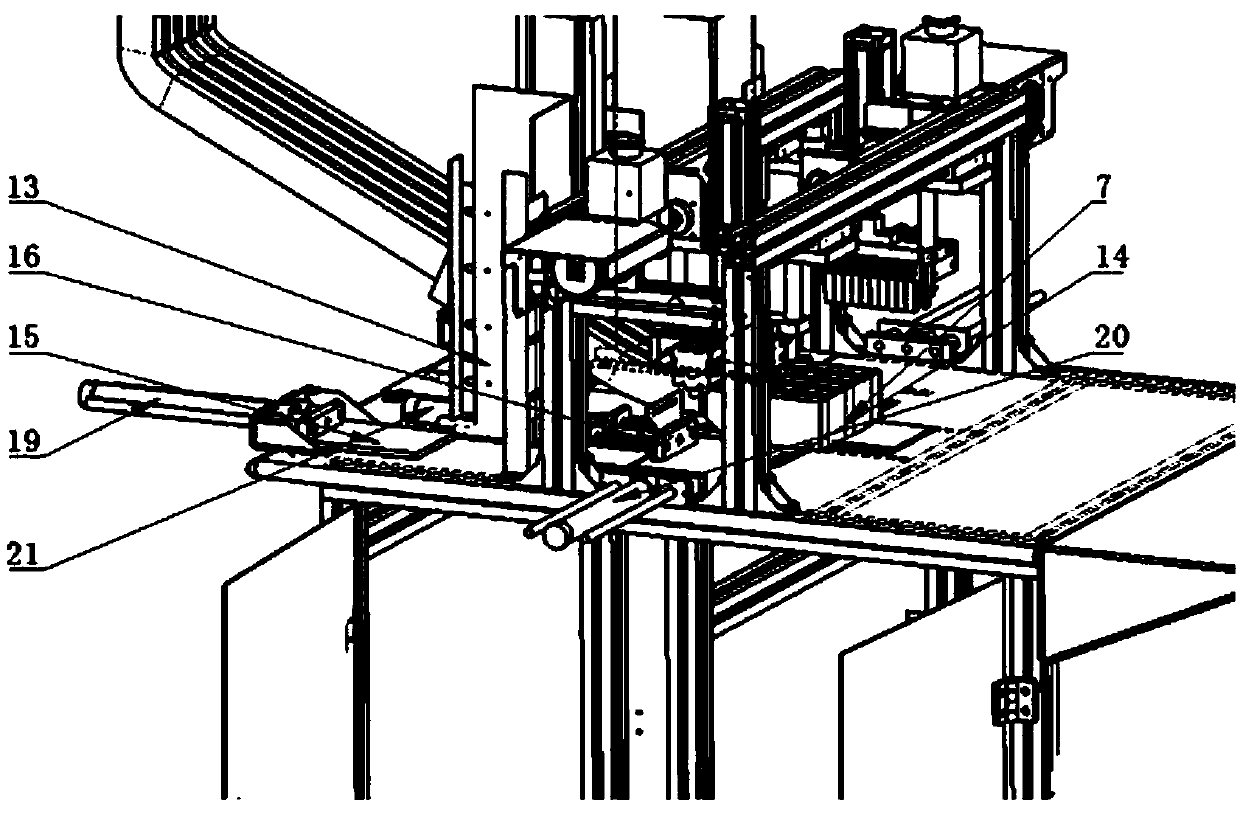

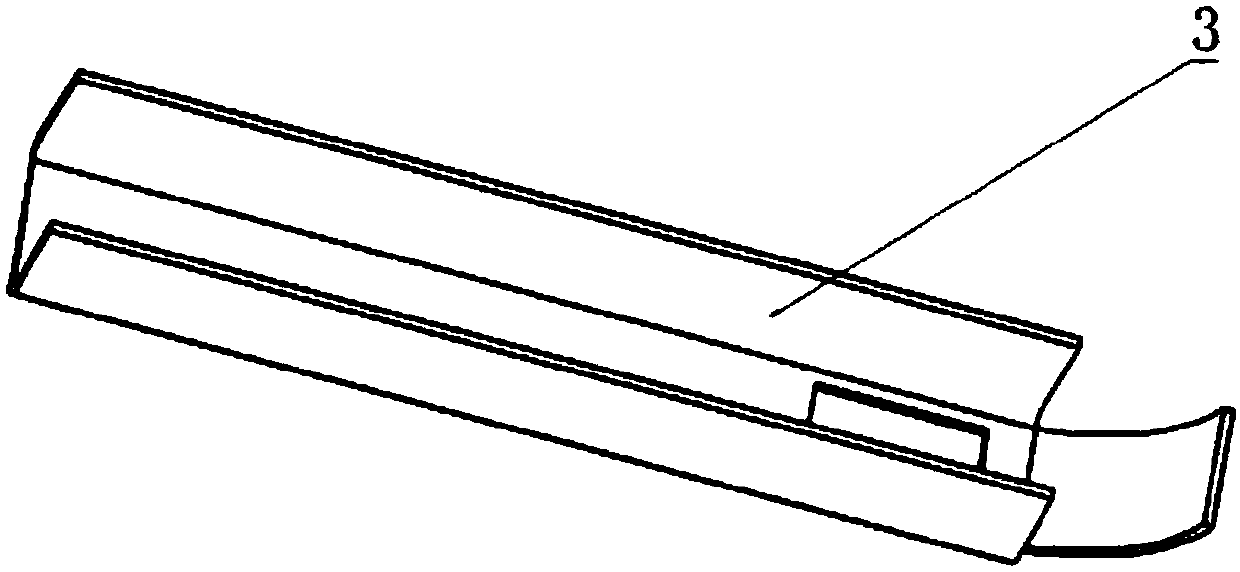

[0026] like figure 1 and figure 2As shown, a multi-track lighter cylinder automatic disk insertion machine includes a base 1, a frame 10, a lighter cylinder sorting device, a disk insertion feeding device, a grabbing device, and a chassis 17; it is characterized in that it also includes an L-shaped bracket 5. Air claw 9, the first cylinder 10, the second cylinder 19, the third cylinder 20, the fourth cylinder 21, the empty storage device 13, the retaining plate 14; the upper end of the base 1 is placed with a vibration plate 2; The lighter cylinder sorting device includes a vibration plate 2 and a sieve material plate 3. A height limit bar 22 is installed on the vibration plate 2. The vibration plate 2 is connected with the sieve material plate 3 through an output slide rail. The opening of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com