Direct-penetration microwave heating curing method for multidirectional carbon fiber reinforced composite material

A technology for reinforcing composite materials and composite materials, which is applied in the field of composite material heating and forming, and can solve the problems that parts cannot be heated by microwaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the accompanying drawings and embodiments.

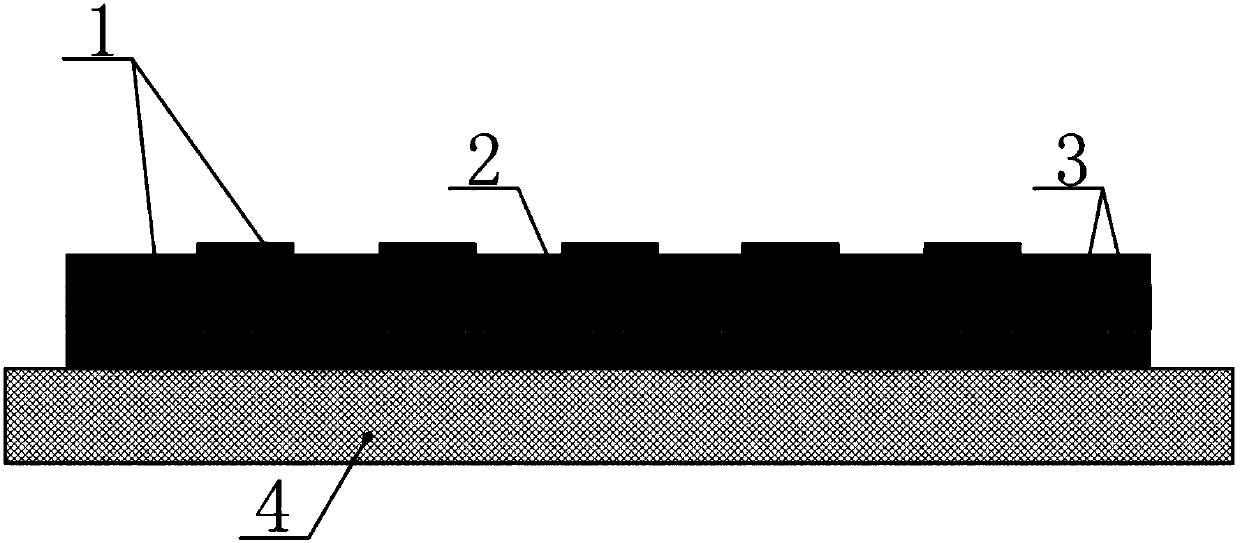

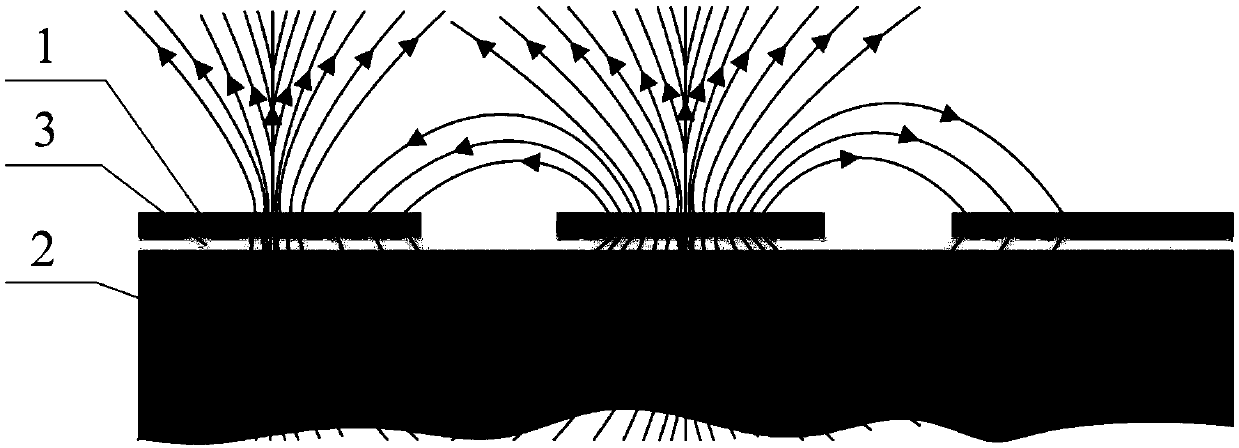

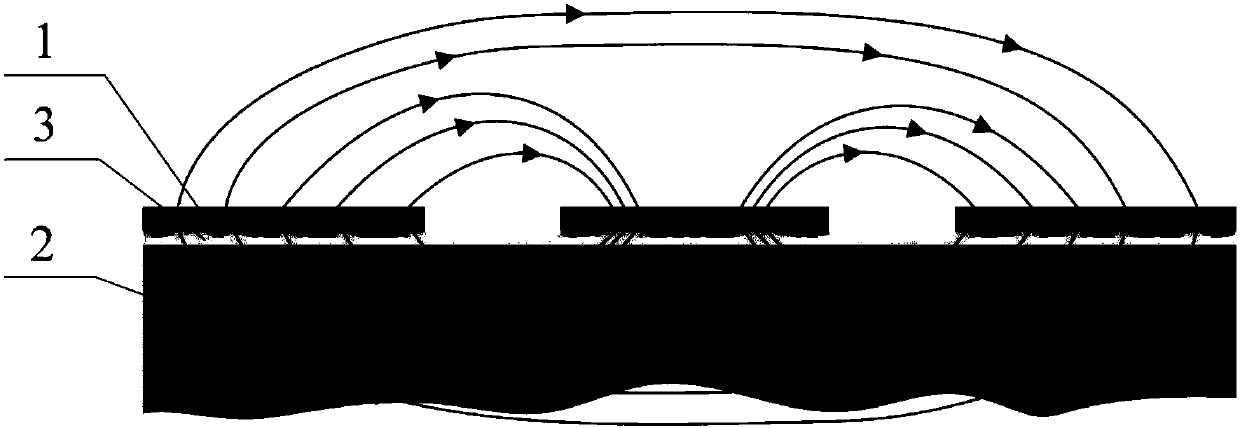

[0017] like Figure 1-3 shown.

[0018] The composite material of this embodiment adopts 18 layers of continuous carbon fiber reinforced bismaleimide resin matrix composite material, and the layup sequence is [0 / 45 / 90 / -45 / 0 / 45 / 90 / 0 / 45] 2 . First, paste a 0.01mm-thick metal copper foil tape on the surface of the wave-transmitting ceramic mold, with a width of 12mm, and the copper foils are parallel to each other with a spacing of 15mm. After the area where the composite material is laid on the surface of the mold is covered with copper foil, a non-porous release cloth is placed. The laying area of the release cloth is larger than that of the composite material and the metal grid array to ensure mutual insulation between the composite material and the metal grid array. Secondly, a multi-directional layered continuous carbon fiber reinforced bismaleimi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com