Linseed dehulling process

A technology of linseed husk and linseed, which is applied in the direction of solid separation, separating solid from solid with air flow, and producing fat, etc. It can solve the problems that the effective utilization rate of linseed cannot be further increased, and the separation degree of husk and kernel is high. The effect of increasing temperature, improving heat utilization rate, and avoiding extrusion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

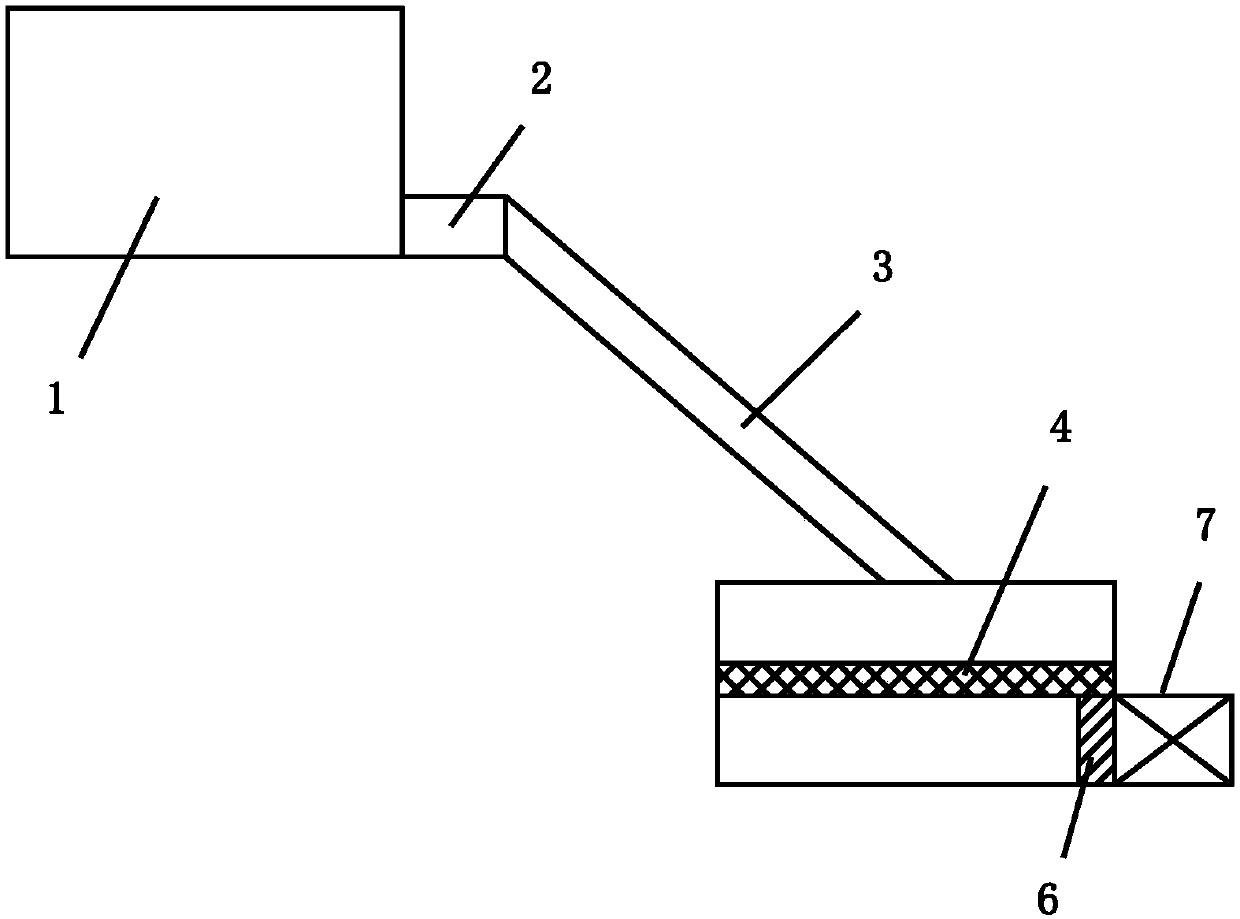

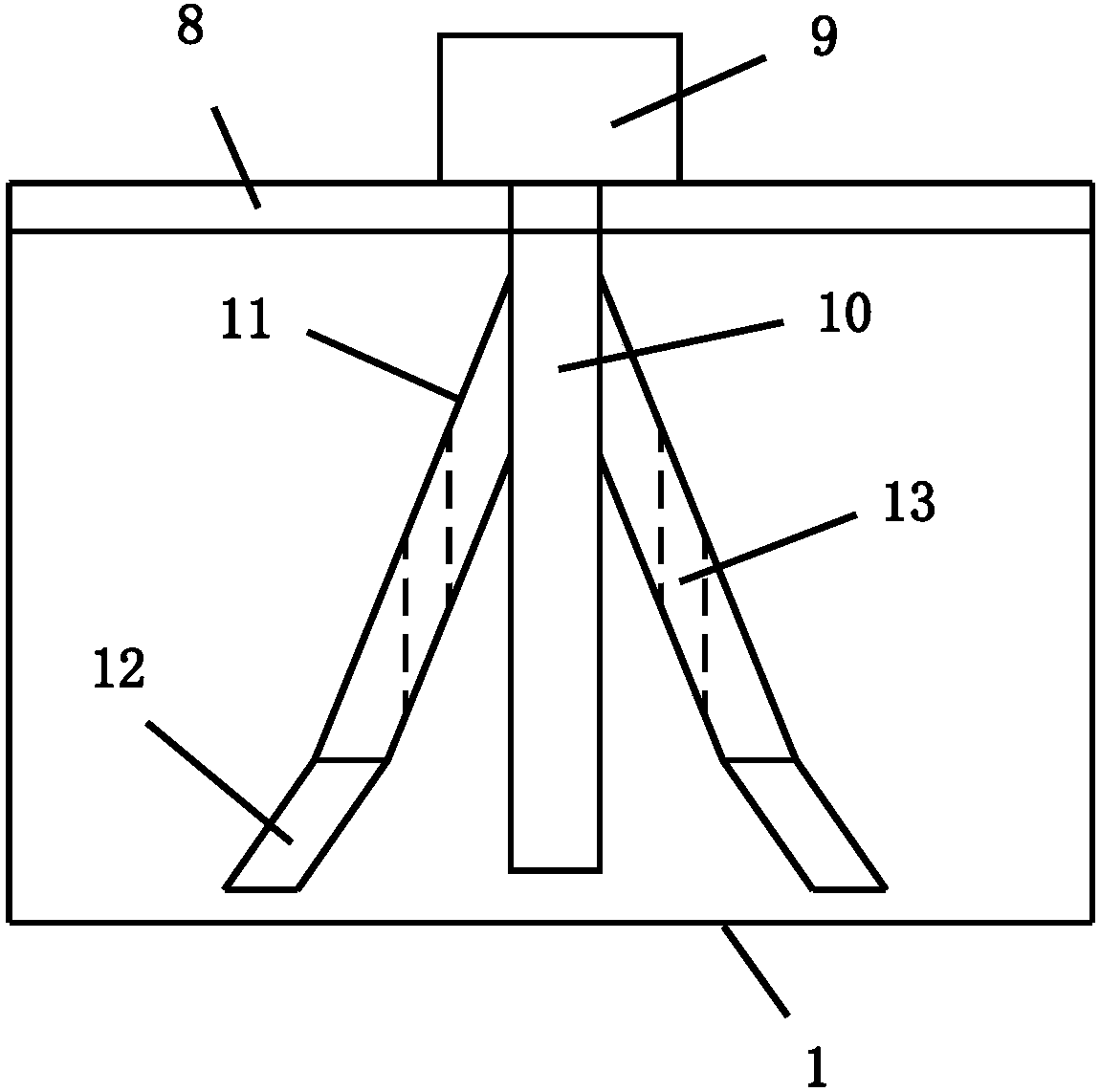

[0026] refer to Figure 1-5 , a flaxseed peeling process is characterized in that comprising the following steps:

[0027] A. Place the flaxseed in the frying pan 1, heat to 105°C, and stir evenly for 20 minutes;

[0028] B. The frying pan 1 is connected to the peeling mechanism 3 through the conveying pipe 2, and the flaxseed is transported to the peeling mechanism 3 through the conveying pipe 2, and the peeling mechanism 3 performs peeling treatment on the flaxseed, and uses dry ice to cool the flaxseed during the process;

[0029] C, a vibrating screen 4 is arranged below the peeling mechanism 3, a heating wire 5 is arranged in the vibrating screen 4, a filter screen 6 is arranged below the vibrating screen 4, and a negative pressure fan 7 is connected to the outside of the filter screen 6; flaxseed passes through the peeling mechanism 3 After treatment, it falls onto the vibrating screen 4, and the vibrating screen 4 is heated to 75°C to separate the linseed kernels and l...

Embodiment 2

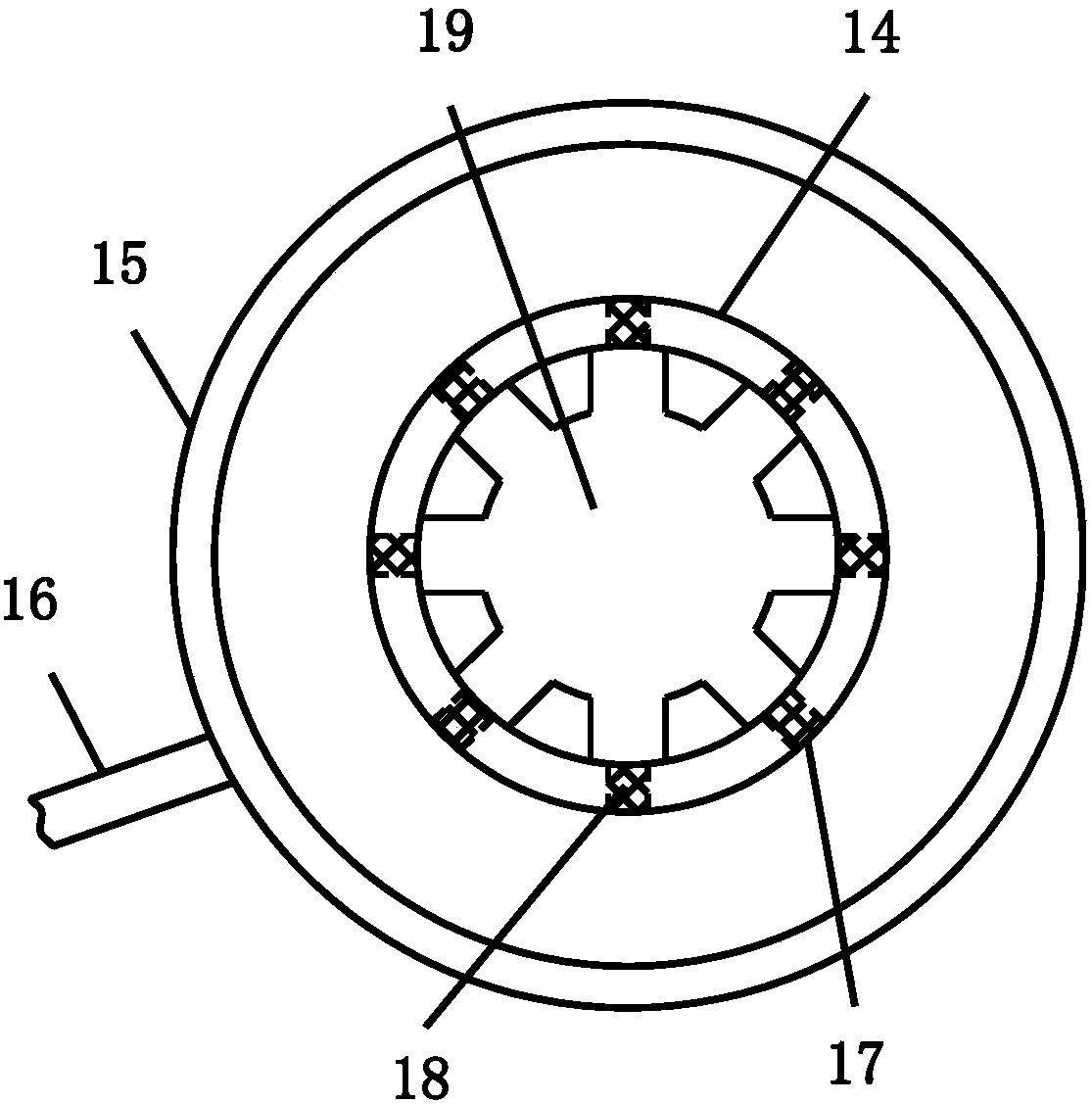

[0037] refer to Image 6 , This embodiment is improved on the basis of Embodiment 1. Bearings 33 are movably installed on both sides of the installation groove 20 through springs 32 , and the rotating shaft 21 is installed in the bearings 33 . The up and down movement of the pressure roller 22 can be realized by movably installing the rotating shaft 21 . Therefore, the arc-shaped groove 23 on the surface of the pressing roller 22 can make the linseed enter into the gap between the pressing roller 22 and the installation groove 20 to be squeezed and crushed, thereby further improving the peeling rate of the linseed. Use the flaxseed identical with embodiment 1 to carry out comparative test:

[0038]

[0039]

Embodiment 3

[0041]This embodiment is improved on the basis of embodiment 2, and the air output of the negative pressure fan is controlled at 90% of the air intake of the compressed air pipe. Through this setting, the vibrating screen 4 can be in a positive pressure state, and the turbulence of the air flow can be used to improve the floating separation effect of the linseed skin, thereby improving the separation efficiency of the husk and kernel. Use the flaxseed identical with embodiment 2 to carry out comparative test:

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com