Activated carbon adsorption process

An activated carbon adsorption and process technology, applied in the direction of using liquid separation agent, gas treatment, steam condensation, etc., can solve the problems of standard discharge, shortening the service life of activated carbon, easy to block activated carbon, etc., to reduce harmful substances, good treatment effect, improve Adsorptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

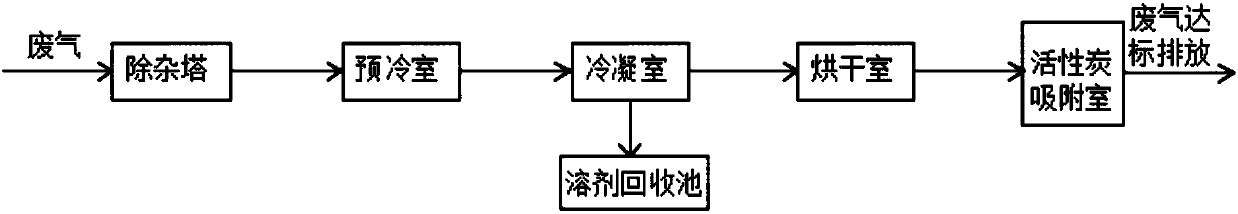

Method used

Image

Examples

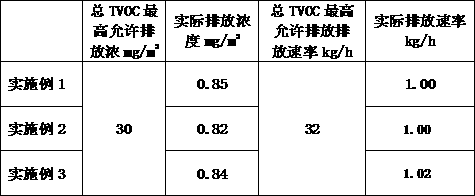

Embodiment 1

[0021] 1) Exhaust gas removal treatment

[0022] The exhaust gas is introduced by the fan to the bottom of the impurity removal tower, and moves from bottom to top. The top of the impurity removal tower is sprayed, and the water contacts the exhaust gas countercurrently from top to bottom. The exhaust gas continues to be introduced into the pre-cooling room by the fan, and the spray water falls into the storage tank. pool;

[0023] 2) Exhaust gas precooling

[0024] Exhaust gas enters the pre-cooling chamber, the wall of the pre-cooling chamber is provided with a jacket, and the cooling water circulates in the jacket from bottom to top to reduce the temperature of the pre-cooling chamber;

[0025] 3) Exhaust gas condensation

[0026] After the exhaust gas comes out of the pre-cooling chamber described in step 2), it enters the condensation chamber, and the organic matter in the exhaust gas condenses into a liquid state and is separated from the gas. The liquid organic matter...

Embodiment 2

[0032] 1) Exhaust gas removal treatment

[0033] The exhaust gas is introduced by the fan to the bottom of the impurity removal tower, and moves from bottom to top. The top of the impurity removal tower is sprayed, and the water contacts the exhaust gas countercurrently from top to bottom. The exhaust gas continues to be introduced into the pre-cooling room by the fan, and the spray water falls into the storage tank. pool;

[0034] 2) Exhaust gas precooling

[0035] Exhaust gas enters the pre-cooling chamber, the wall of the pre-cooling chamber is provided with a jacket, and the cooling water circulates in the jacket from bottom to top to reduce the temperature of the pre-cooling chamber;

[0036] 3) Exhaust gas condensation

[0037] After the exhaust gas comes out of the pre-cooling chamber described in step 2), it enters the condensation chamber, and the organic matter in the exhaust gas condenses into a liquid state and is separated from the gas. The liquid organic matter...

Embodiment 3

[0043] 1) Exhaust gas removal treatment

[0044] The exhaust gas is introduced by the fan to the bottom of the impurity removal tower, and moves from bottom to top. The top of the impurity removal tower is sprayed, and the water contacts the exhaust gas countercurrently from top to bottom. The exhaust gas continues to be introduced into the pre-cooling room by the fan, and the spray water falls into the storage tank. pool;

[0045] 2) Exhaust gas precooling

[0046] Exhaust gas enters the pre-cooling chamber, the wall of the pre-cooling chamber is provided with a jacket, and the cooling water circulates in the jacket from bottom to top to reduce the temperature of the pre-cooling chamber;

[0047] 3) Exhaust gas condensation

[0048] After the exhaust gas comes out of the pre-cooling chamber described in step 2), it enters the condensation chamber, and the organic matter in the exhaust gas condenses into a liquid state and is separated from the gas. The liquid organic matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com