Solid phase regeneration method of waste ternary lithium ion battery positive electrode material

A technology for lithium-ion batteries and ternary lithium batteries, which is applied in the field of solid-phase regeneration of positive electrode materials for waste ternary lithium-ion batteries, can solve the problems of unsuitability for industrial cycle production, low recovery efficiency, and large consumption of auxiliary materials, etc., and achieve cost reduction, Repair the effect of large amount of regeneration and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

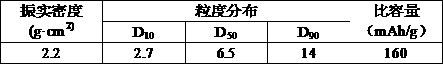

Embodiment 1

[0028] The invention discloses a method for solid phase regeneration of positive electrode materials of waste ternary lithium ion batteries, which comprises the following steps:

[0029] (1) Discharge the residual power of the waste ternary lithium battery, then disassemble the battery finely, take out the positive electrode, wash and dry the positive electrode;

[0030] (2) After heat-treating the dried waste ternary lithium battery cathode sheet at 500°C for 6 hours, sieve and separate the heat-treated ternary cathode material from aluminum foil or conductive agent;

[0031] (3) Through the elemental analysis of the pretreated waste ternary cathode material, and then add lithium source, cobalt source, nickel source and manganese source to adjust the molar ratio of elements to nLi:nCo:nNi:nMn=1:x:y :z, where x+y+z=1;

[0032] (4) Add lithium source, cobalt source, nickel source and manganese source to the waste ternary cathode material, and then carry out mixed ball milling....

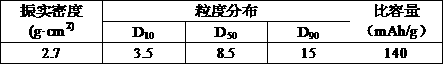

Embodiment 2

[0038] The invention discloses a method for solid phase regeneration of positive electrode materials of waste ternary lithium ion batteries, which comprises the following steps:

[0039] (1) Discharge the residual power of the waste ternary lithium battery, then disassemble the battery finely, take out the positive electrode, wash and dry the positive electrode;

[0040] (2) After heat-treating the dried waste ternary lithium battery cathode sheet at 400°C for 4 hours, sieve and separate the heat-treated ternary cathode material from aluminum foil or conductive agent;

[0041] (3) Through the elemental analysis of the pretreated waste ternary cathode material, and then add lithium source, cobalt source, nickel source and manganese source to adjust the molar ratio of elements to nLi:nCo:nNi:nMn=1:x:y :z, where x+y+z=1;

[0042] (4) Add lithium source, cobalt source, nickel source and manganese source to the waste ternary cathode material, and then carry out mixing ball milling...

Embodiment 3

[0048] The invention discloses a method for solid phase regeneration of positive electrode materials of waste ternary lithium ion batteries, which comprises the following steps:

[0049](1) Discharge the residual power of the waste ternary lithium battery, then disassemble the battery finely, take out the positive electrode, wash and dry the positive electrode;

[0050] (2) After heat-treating the dried waste ternary lithium battery cathode sheet at 300°C for 8 hours, sieve and separate the heat-treated ternary cathode material from aluminum foil or conductive agent;

[0051] (3) Through the elemental analysis of the pretreated waste ternary cathode material, and then add lithium source, cobalt source, nickel source and manganese source to adjust the molar ratio of elements to nLi:nCo:nNi:nMn=1:x:y :z, where x+y+z=1;

[0052] (4) Add lithium source, cobalt source, nickel source and manganese source to the waste ternary cathode material, and then carry out mixed ball milling. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com