Shear stress sensor based on 1-3 type cement-based piezoelectric composites and preparation method thereof

A piezoelectric composite material, cement substrate technology, applied in material selection for piezoelectric devices or electrostrictive devices, fabrication/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices Telescopic device and other directions to achieve high sensitivity, good coupling effect, and good anti-interference effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

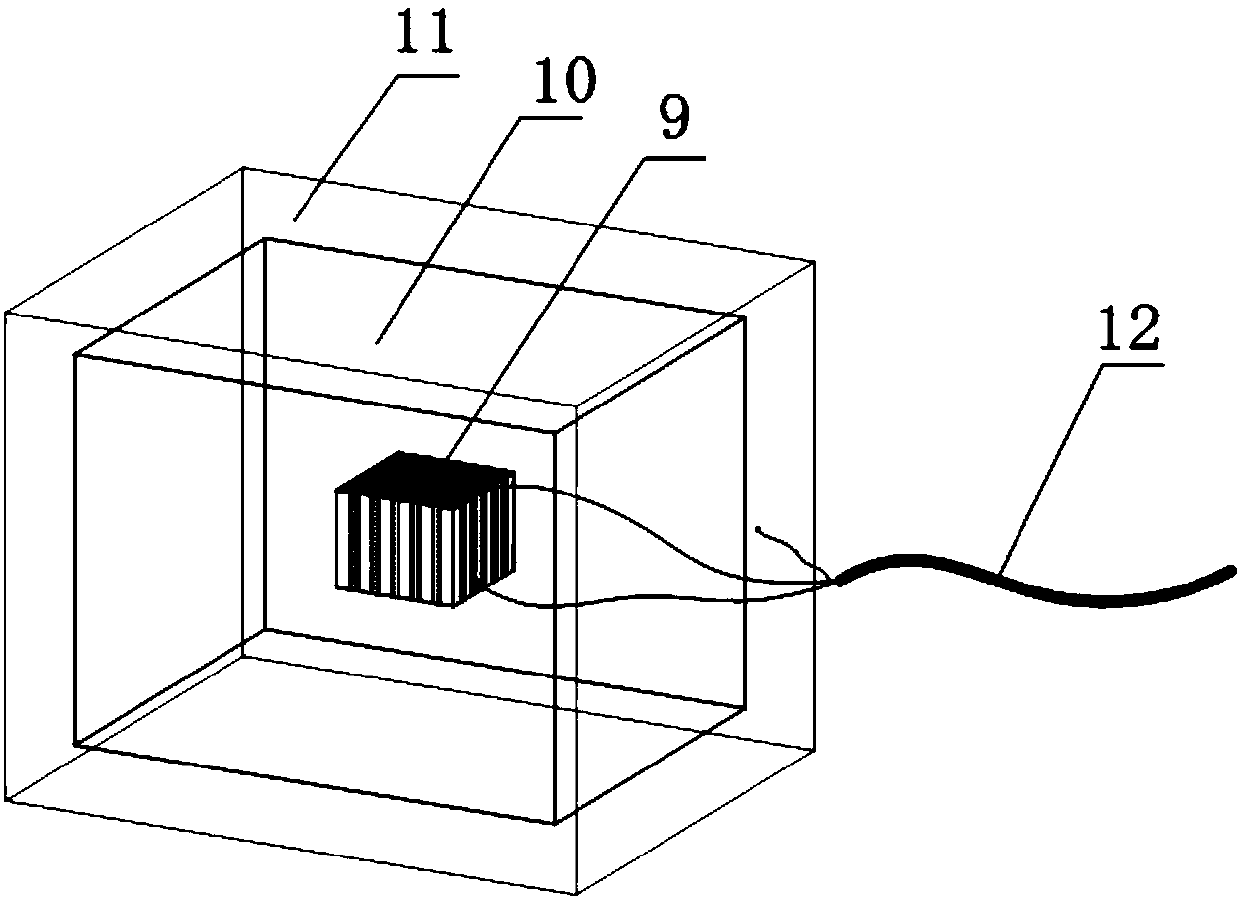

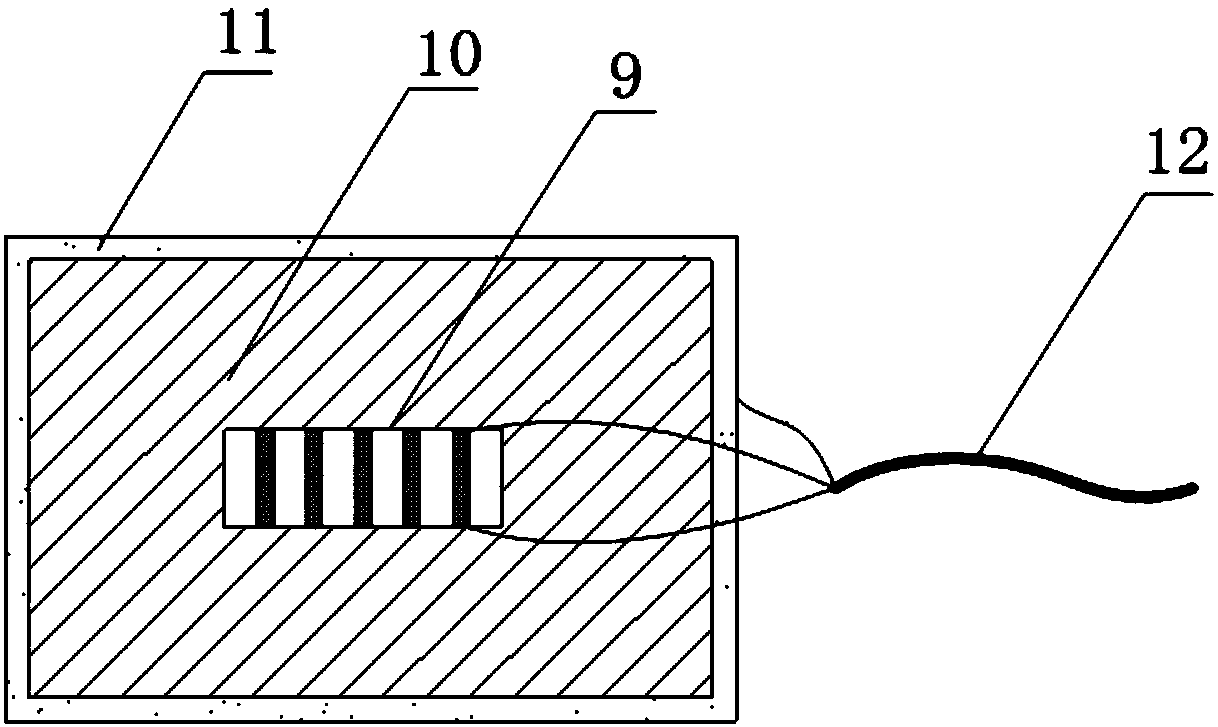

[0039] In order to more clearly illustrate the embodiments of the present invention and / or the technical solutions in the prior art, the specific implementation manners of the present invention will be described below with reference to the accompanying drawings. Obviously, the drawings in the following description are only embodiments of the present invention, and those skilled in the art can also obtain other drawings based on these drawings and obtain other implementation.

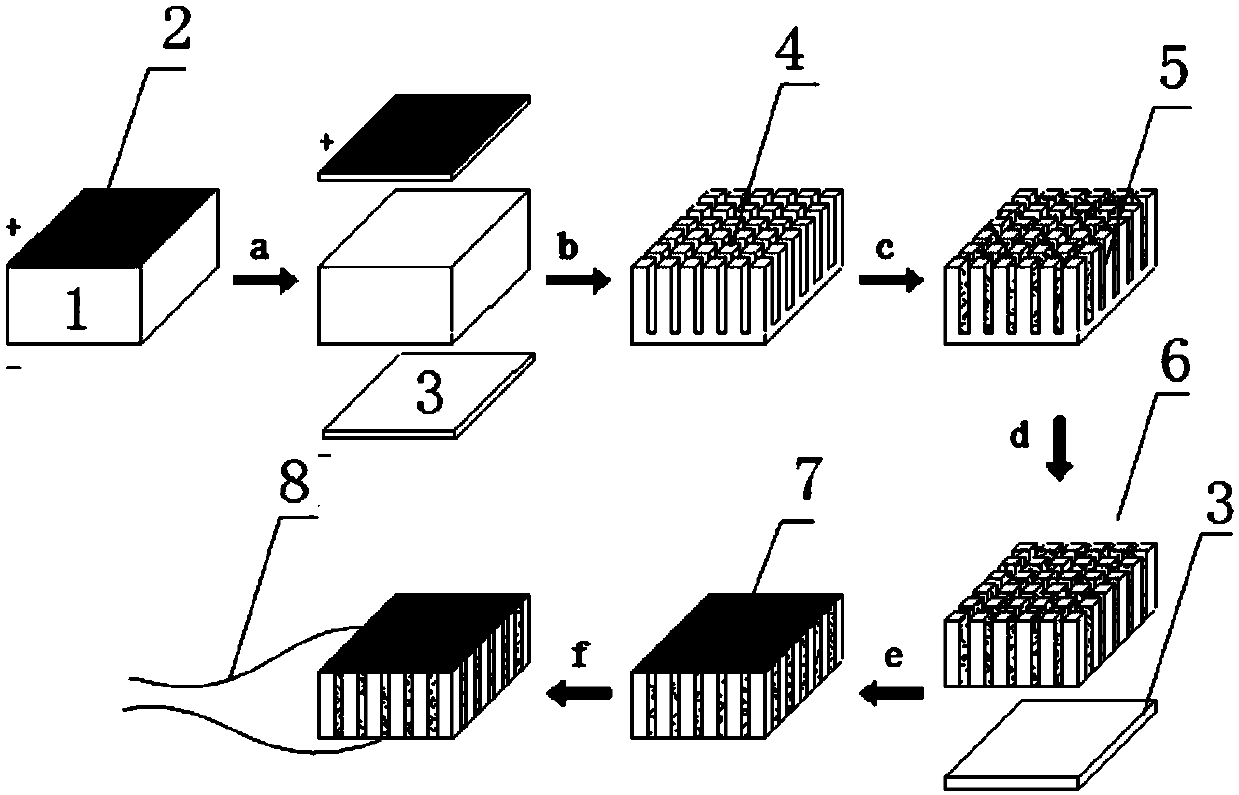

[0040] See figure 1 , in this specific embodiment, the 1-3 type cement-based piezoelectric composite material element is prepared by cutting-casting method, the main raw materials include piezoelectric ceramic block and cement substrate, and the specific process is as follows:

[0041] (101) Remove the polarized electrode 2 of the polarized piezoelectric ceramic block 1 , and place the piezoelectric ceramic block 1 on the base 3 . The piezoelectric ceramic block may be lead zirconate titanate piezoelec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com