Excitation winding structure

A winding structure and excitation technology, applied in coil manufacturing and other directions, can solve the problems of low work efficiency, waste of time, and the inability to perform multiple windings at one time, so as to improve work efficiency, reduce operating time, and accurately control winding coils. effect of numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

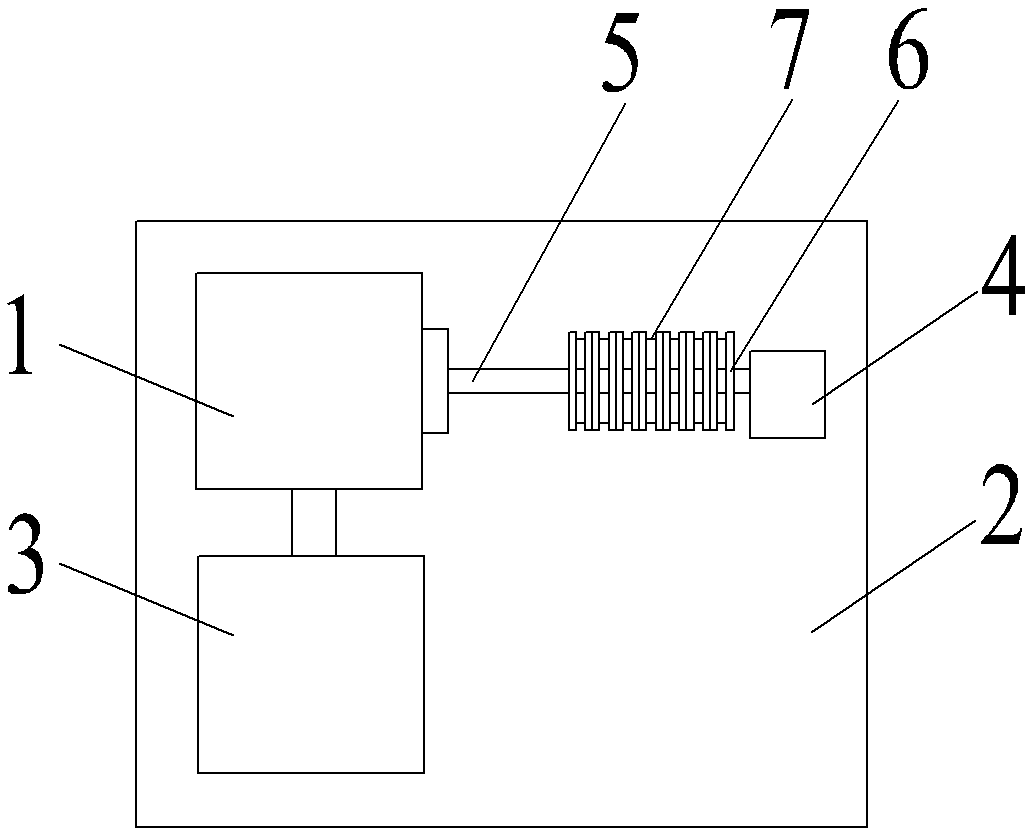

[0007] Such as figure 1 As shown, the present invention includes an AC motor 1, a workbench 2, and a frequency converter 3. The AC motor 1 is mounted on the workbench 2, and the frequency converter 3 is connected to the AC motor 1. Controlled by the frequency converter 3, the start-up of the AC motor 1 can be precisely controlled. Stop and rotate the number of turns, so as to accurately control the number of coils, reduce the operating time, and improve work efficiency. The support seat 4 is installed on the workbench 2 opposite to the output end of the AC motor 1, and the drive shaft connected to the output end of the AC motor 1 5 is connected to the support base 4, and the drive shaft 5 is equipped with a wire rack 6, and the wire rack 6 is provided with 7 grooves 7, and the winding ends are respectively placed in the 7 grooves 7 of the wire rack 6, Then multiple windings can be realized at the same time, satisfying the high-volume and high-efficiency production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com