Rolling bearing outer ring defect full-size quantitative diagnosis method

A technology for rolling bearings and diagnostic methods, which is applied in the direction of mechanical bearing testing, measuring devices, and special data processing applications, etc. It can solve the problems of misdiagnosing large defects into small defects, large spacing, and failure to correctly diagnose the size of outer ring defects, etc., so as to avoid misdiagnosis problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The diagnostic method of the present invention will be described in detail below with reference to the drawings and embodiments, but the protection scope of the present invention is not limited to the embodiments.

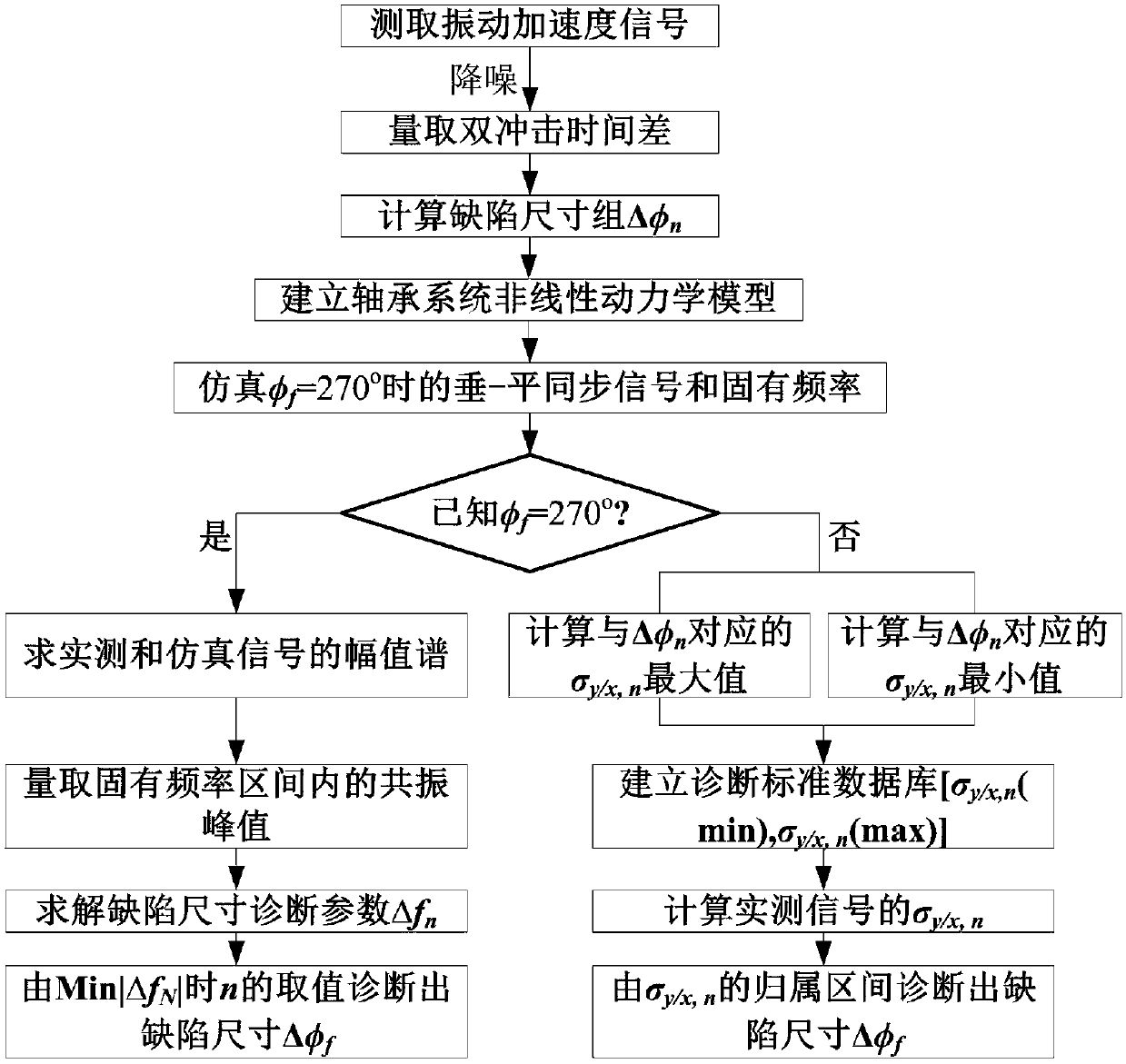

[0044] Such as figure 1 As shown, it is a work flow chart of a full-scale quantitative diagnosis method for rolling bearing outer ring defects of the present invention. The detailed steps are as follows.

[0045] Step 1 Preliminary diagnosis of the basic size and optional size of the outer ring defect of the rolling bearing,

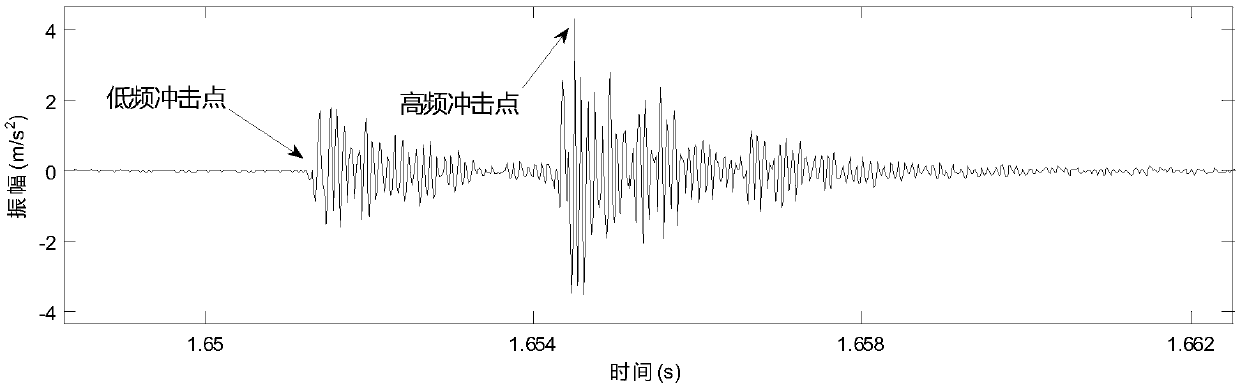

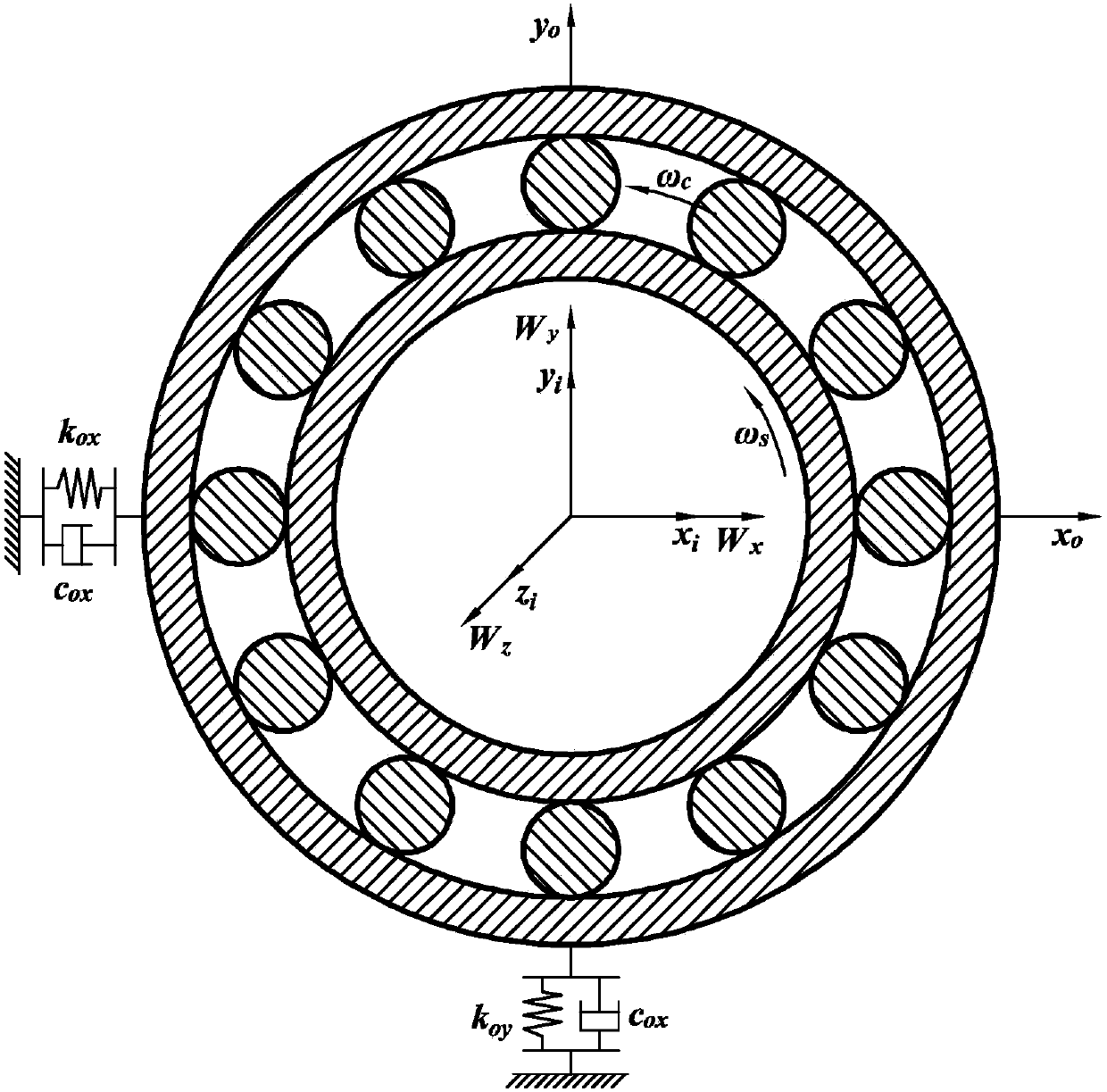

[0046] In this embodiment, the known parameters of the bearing system to be diagnosed are: the number of bearing balls N b =8, cage rotation frequency f c =3Hz, sampling frequency F s =65536Hz, number of data points N=131072, number of balls N b =8, defect angular position φ f unknown. Install a pair of vibration acceleration sensors to the horizontal measuring point and vertical measuring point of the bearing seat respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com