System and method for testing light distribution of light spot

A test method and technology of a test system, applied in the field of test systems for spot light distribution, can solve the problems of high maintenance cost, influence of control accuracy and reading accuracy, high equipment manufacturing cost, small volume and area, less hardware and software, Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

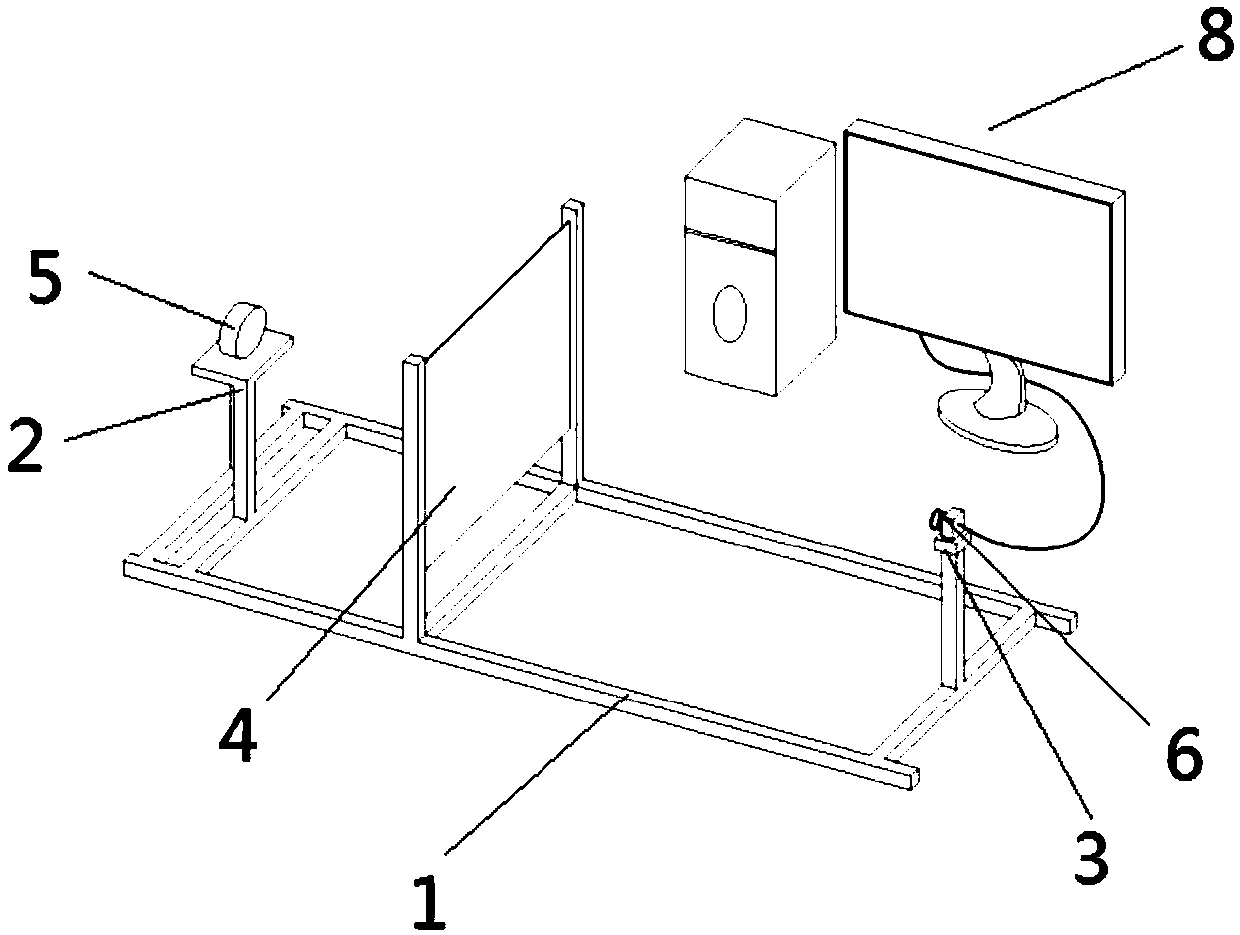

[0038] Such as Figure 1~Figure 8 Shown, a kind of test method of spot light distribution, it comprises the following steps:

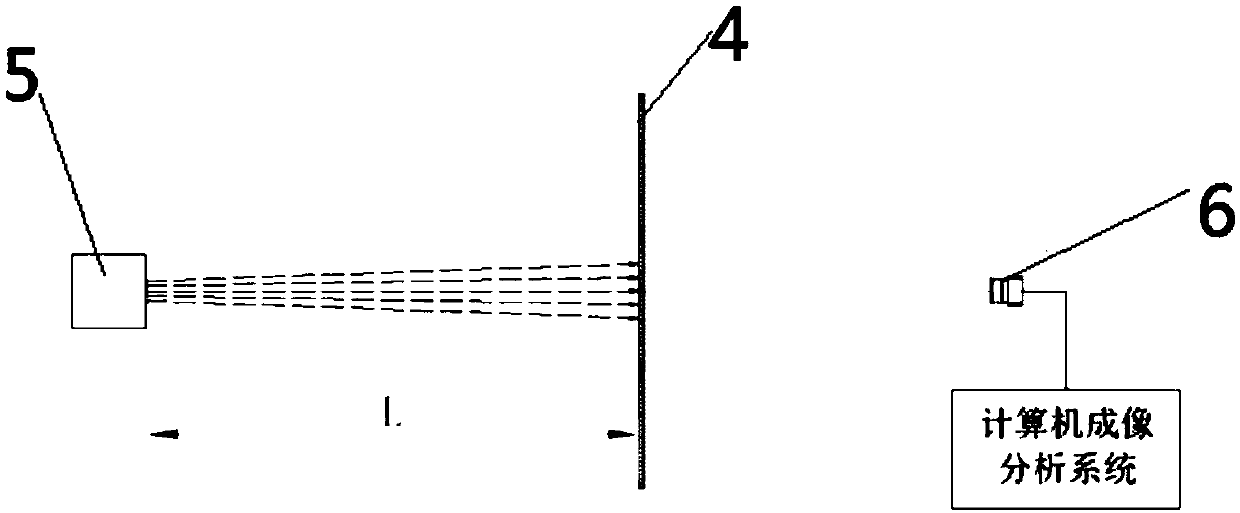

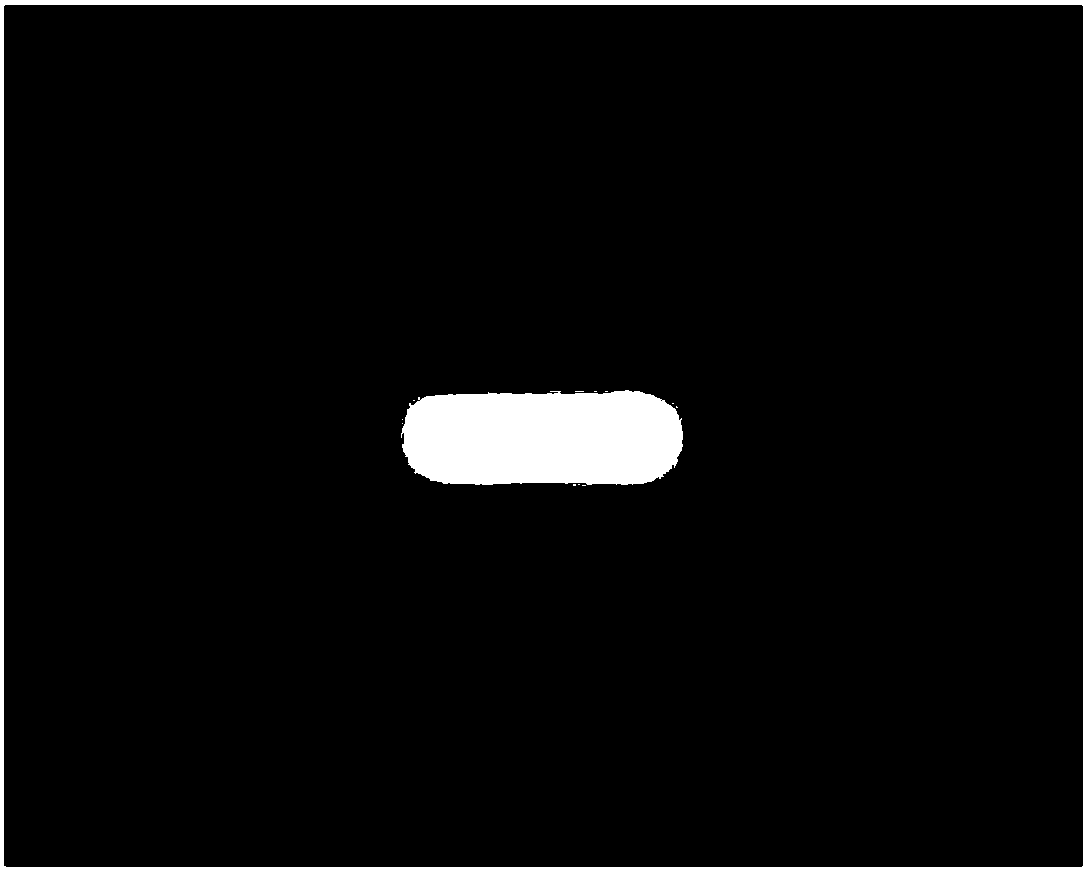

[0039] Such as figure 1 and figure 2 As shown, in step S1, the light emitted by the light source product 5 to be tested is irradiated onto the translucent imaging plate 4, and bright spots illuminated by the light source product 5 to be tested appear on the other side of the translucent imaging plate 4, as shown in FIG. image 3 As shown, a camera 6 is placed on the other side of the translucent imaging plate 4 relative to the light source product 5 to be tested, and the camera 6 takes pictures of bright spots. After the imaging analysis system of the computer 8, the distance L of the light source product 5 to be tested is calculated. Spot brightness distribution and size information; wherein, preferably, the range of L is 0.5-1m.

[0040] Step S2, placing a ruler 7 on the side of the translucent imaging plate 4 facing the camera 6, such as Figur...

Embodiment 2

[0048] Such as figure 1 and figure 2 As shown, a test system for spot light distribution, which adopts the test method for spot light distribution as described above for testing, includes a test frame 1 and a computer 8, and the two ends of the test frame 1 are respectively provided with product placement racks 2 and a camera placement frame 3, the middle part of the test frame 1 is provided with a translucent imaging plate 4, the light source product 5 to be tested is placed on the product placement frame 2, the camera 6 is placed on the camera placement frame 3, and the translucent imaging The plate 4 is located on the vertical plane connecting the light source product 5 to be tested and the camera 6; the light emitted by the light source product 5 to be tested is imaged on the translucent imaging plate 4; The image is connected with the computer 8, and the imaging analysis system of the computer 8 obtains the information of the camera 6 for analysis. The central axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com