Uniform and lower exhaust type large-area workbench

A workbench and large-area technology, applied in the direction of workbench, ventilation system, manufacturing tools, etc., can solve the problems of increasing the risk of workers suffering from occupational disease hazard accidents, the inability to use middle and lower exhaust, and the difficulty of achieving wind speed, etc., to achieve protection Occupational health, enhance poison control effect, avoid pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

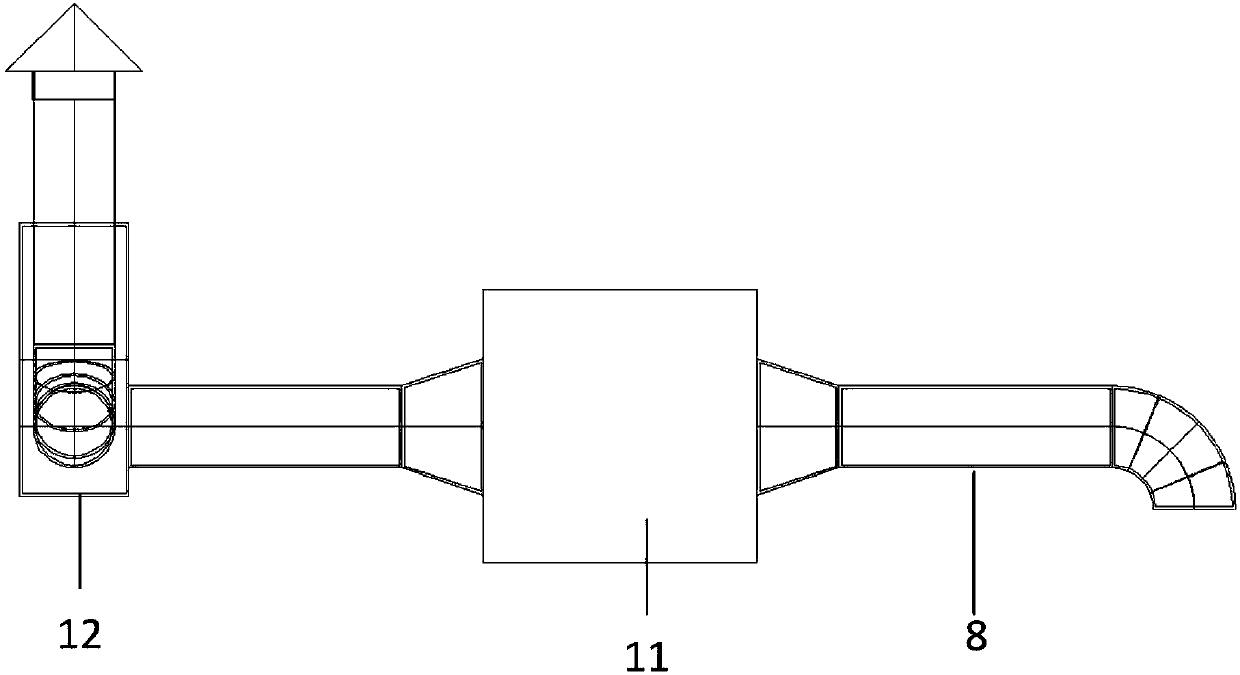

[0022] A large-area uniform lower exhaust workbench, which consists of a workbench shell 1, a porous orifice plate worktop 2, a triangular rectification structure 3, a rectification slit 4, a rectification bottom plate 5, an elbow 6, a variable diameter pipe 7, and an air duct 8. Consisting of a liquid discharge pipe 9, a liquid discharge valve 10, a purification device 11, a fan and a frequency converter 12, an automatic control device 13, and a cover invisible handle 14.

[0023] The laborer walks into the large-area uniform lower exhaust workbench and places the work piece on the porous orifice worktable 2. The automatic control device 13 detects that the operator enters the work area, and automatically turns on the fan and the frequency converter 12. Laborers work on the porous orifice table top 2, and the toxic substances produced during the operation process are rectified by the triangular rectification structure 3 and the rectification bottom plate 5 under the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com