Abrasion-resisting ball hinge controlled on basis of slider-crank mechanism

A crank-slider mechanism and hinge technology, which is applied in the field of ball hinges, can solve the problems of shortening the service life of hinges, increasing costs, and wear of rolling balls.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

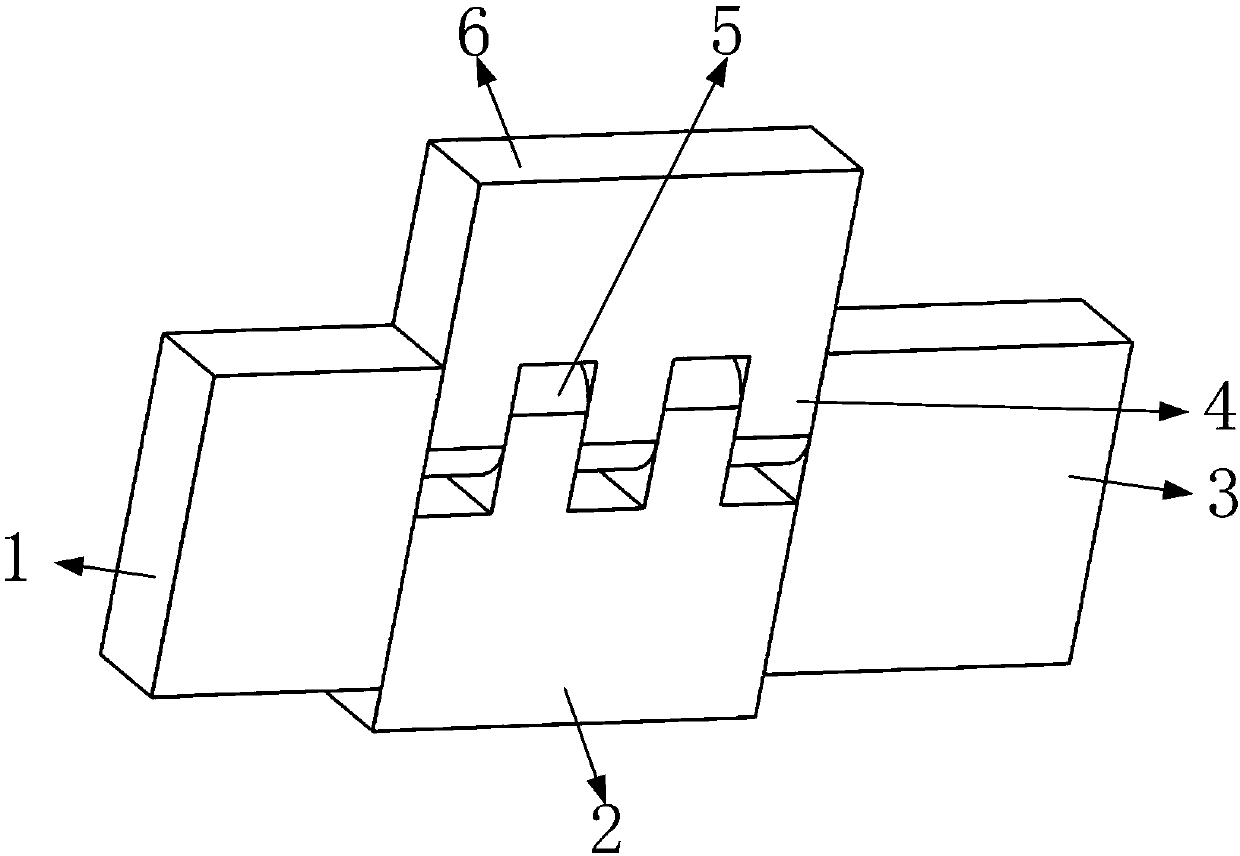

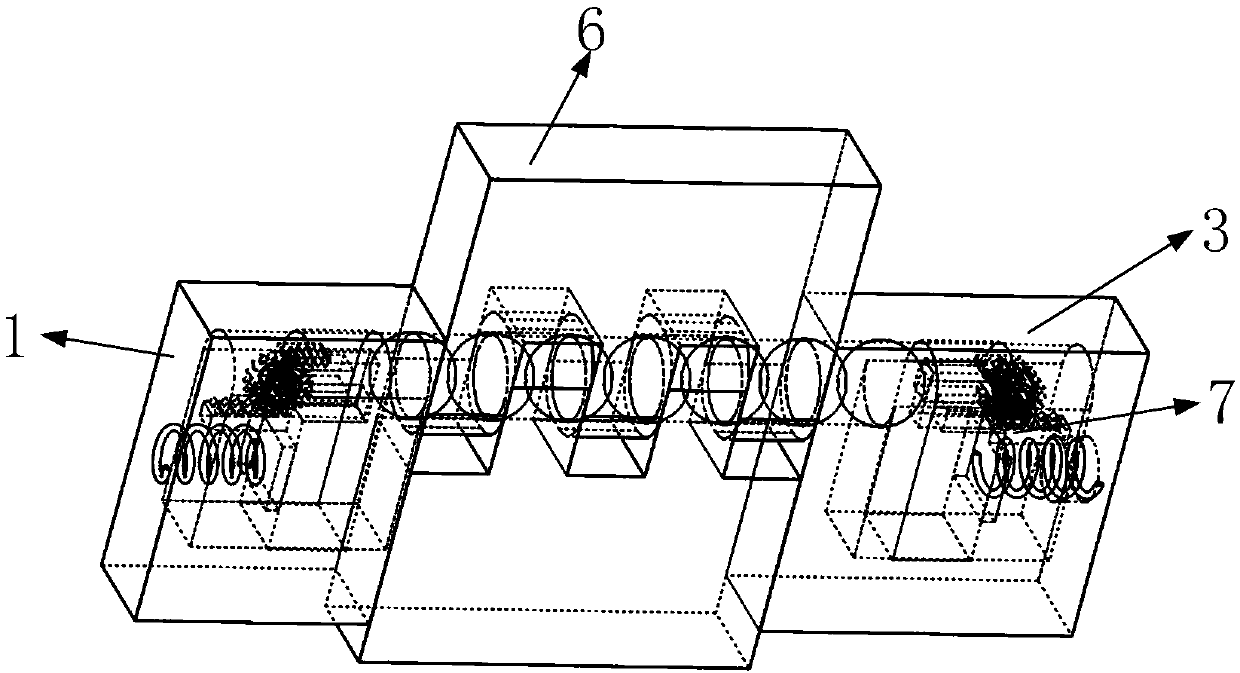

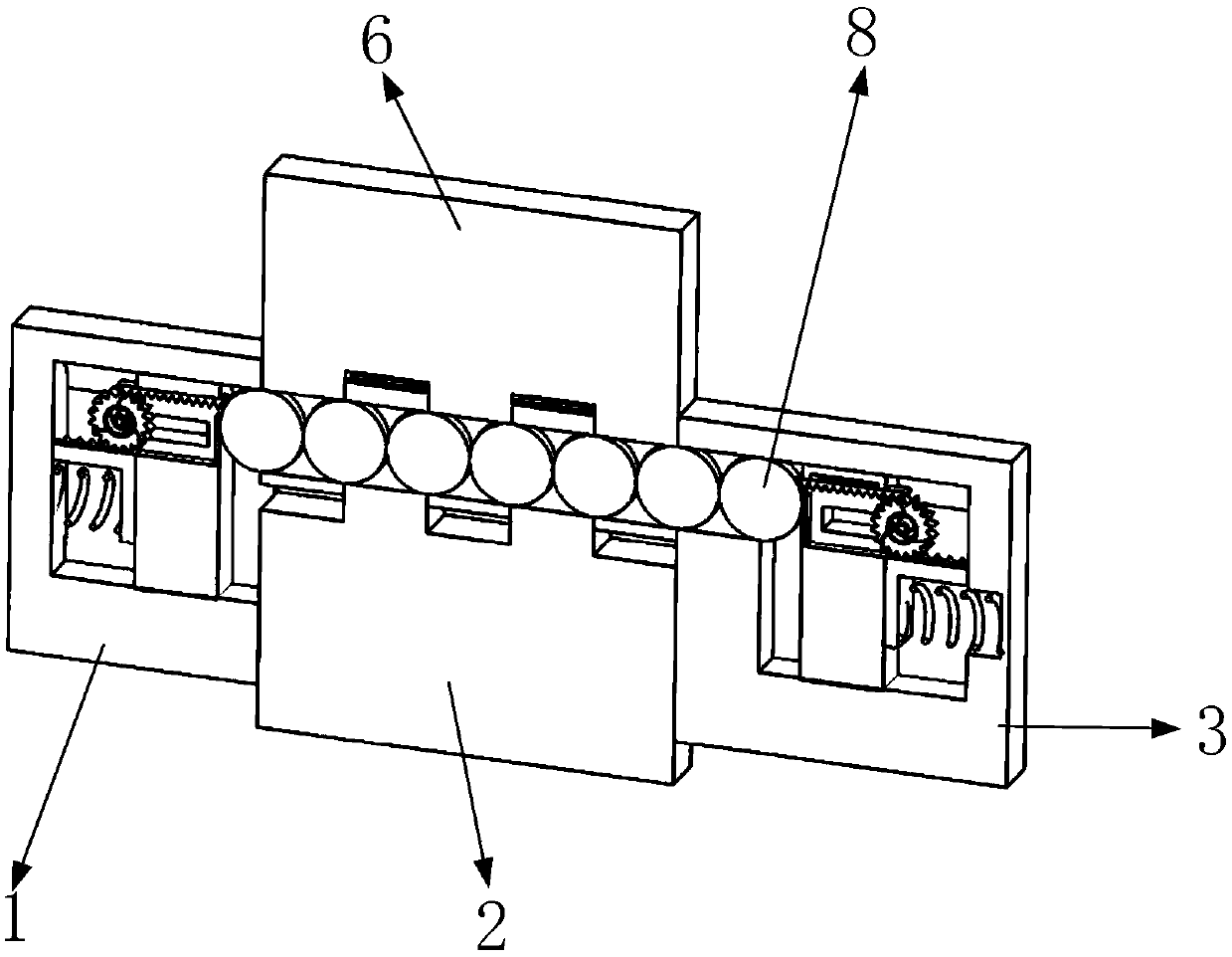

[0050] Such as figure 1 , 2 , 3, it includes the first fixed block 1, the first hinge 2, the second fixed block 3, the first lug 4, the second lug 5, the second hinge 6, the adjustment mechanism 7, the rolling ball 8 , the first housing chamber 9, the round hole 10, the second housing chamber 11, the spring hole 12, such as Figure 4 , 5 As shown, there is a first accommodating chamber 9 on the side of the first fixed block 1; as Figure 8 As shown, the side of the first hinge 2 is installed on the side of the first accommodating cavity 9 of the first fixed block 1; Figure 8 As shown, two second lugs 5 are sequentially installed on the upper end surface of the first hinge 2; as Figure 6 , 7 As shown, there is a round hole 10 on the side of the second fixed block 3, and a second accommodating cavity 11 is opened on the end face of the round hole 10; Figure 7 As shown, there is a spring hole 12 on the end surface of the second accommodation cavity 11; the side of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com