All-plastic submersible electric pump and injection molding process thereof

A submersible electric pump, electric pump technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of corrosion of metal overcurrent parts, difficult to serialize large-scale production, affecting the life of pumps, etc. The effect of small size and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

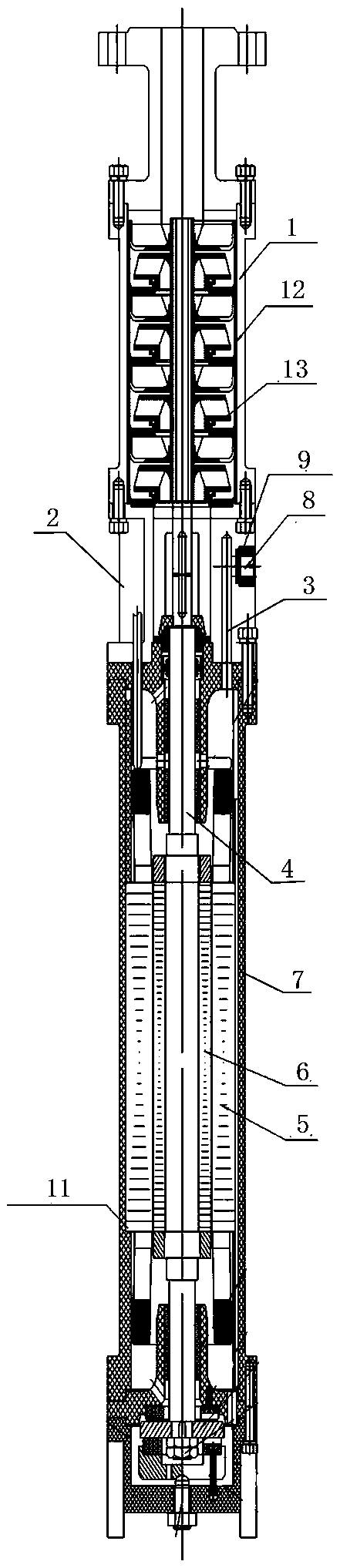

[0025] as attached figure 1 As shown, an all-plastic submersible electric pump includes an injection-molded electric pump main body, an injection-molded overcurrent component arranged in the electric pump main body, and a motor stator 5, a motor rotor 6 and a motor shaft 4 installed inside the injection-molded electric pump main body; The main body of the injection-molded electric pump includes a cylinder 1 wrapped outside the injection-molded flow-through parts, an electric pump casing A2 wrapped outside the water inlet section 3 , and an electric pump casing B7 wrapped outside the motor shaft 4 . The injection-molded flow-passing part includes an impeller 13 and a guide case 12 , and the cylinder 1 plays a role of fixing the impeller 13 and the guide case 12 . The electric pump housing A2 is provided with four holes 8 connected to the water inlet blind hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com