Anti-deformation-type multi-layer wood composite structure with heating function

A composite structure, anti-deformation technology, applied in the field of flooring, can solve problems such as poor applicability and inconvenient interception, and achieve the effects of improving durability, avoiding curling, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

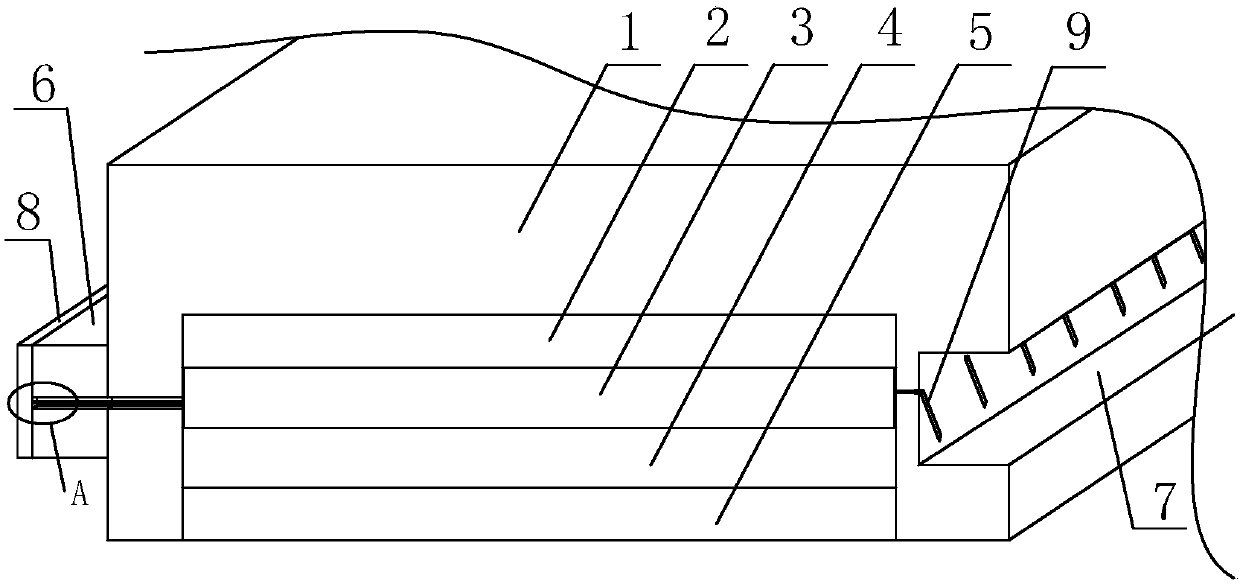

[0025] A form of anti-alteration heating of multi-layer wood composite structures such as figure 1 As shown, it includes a wooden floor body 1, a heat conduction layer 2, a heat generation layer 3, a reflective layer 4 and a heat insulation layer 5 arranged under the wooden floor body 1 in sequence.

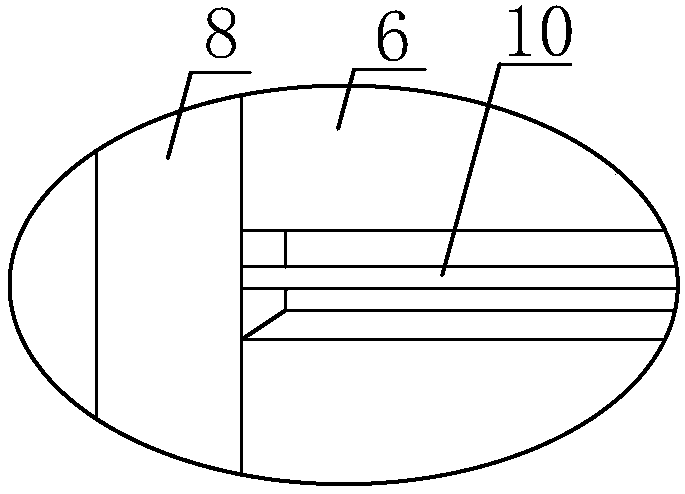

[0026] The wooden floor body 1 is in the shape of a cuboid, and the middle part of the bottom of the wooden floor body 1 has a hollow body arranged along the direction of the long side. Inside the cavity, and the side wall of one long side of the wooden floor body 1 is provided with a protruding strip 6 with the same length as the wooden floor body 1, and the side wall of the other long side of the wooden floor body 1 is provided with a The protruding strip 6 matches the groove 7, and the protruding strip 6 and the groove 7 are both provided with a connecting cable 10 passing through the wooden floor body 1 and communicating with the heating layer 3 .

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the setting method at the position of the connecting cable 10 is optimized in this embodiment, and the specific settings are as follows:

[0029] One side of the protruding strip 6 is fixed on the wooden floor body 1, and the other side of the protruding strip 6 is provided with a guide piece 8, which communicates with the heating layer 3 through a connecting cable 10; There is a connecting piece 9, and the connecting piece 9 is also communicated with the heating layer 3 through another connecting cable 10.

[0030] The length of the guide piece 8 is the same as the length of the wooden floor body 1; the connecting piece 9 is fixed on the first connecting piece connected with the connecting cable 10 on the wooden floor body 1 by one end, and one end is connected with the other end of the first connecting piece. It consists of a fixed second connecting piece, and the angle between the second connecting piece...

Embodiment 3

[0032] The difference between this embodiment and Embodiment 2 is that the structural settings are optimized, and the specific settings are as follows:

[0033] The angle between the second connecting piece and the first connecting piece is set at 95-100 degrees. The heating layer 3 is a nickel-chromium alloy heating layer. The heat conduction layer 2 is made of aerospace grade aluminum alloy material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com