Dry-method-connection plate-type structural system and construction method thereof

A connecting plate type, dry method, applied in building structure, construction and other directions, can solve the problems of insufficient thermal insulation durability, low construction efficiency, etc., and achieve the effect of reducing work types, reasonable overall stress, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

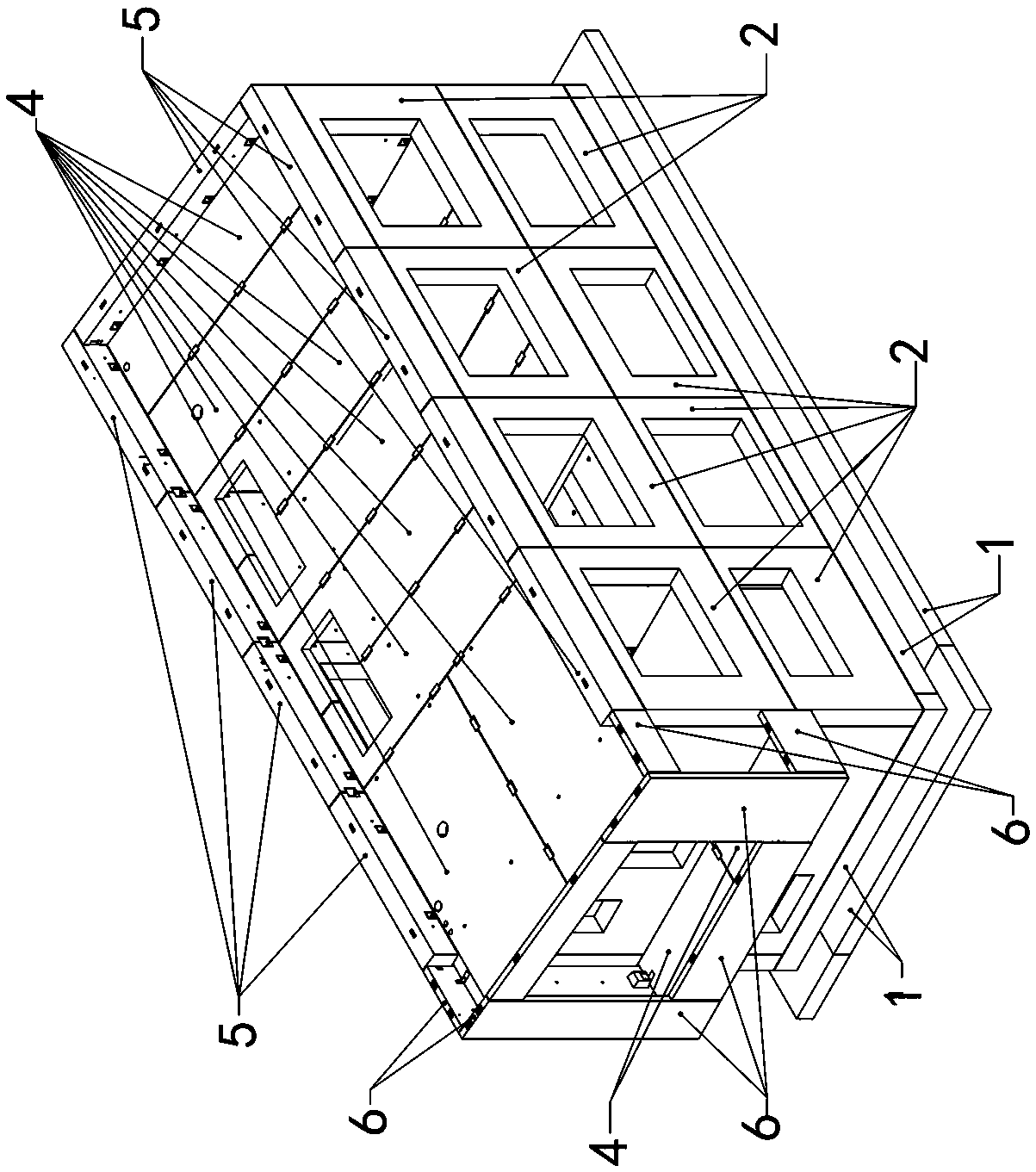

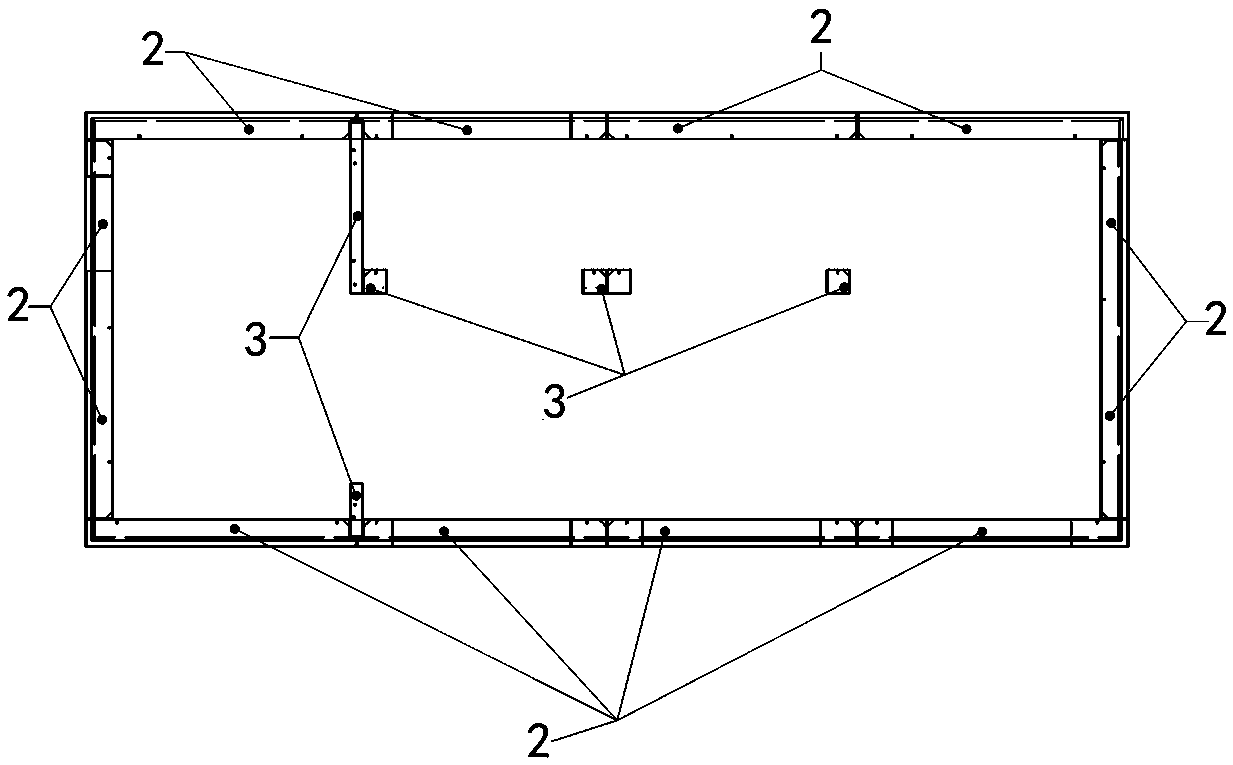

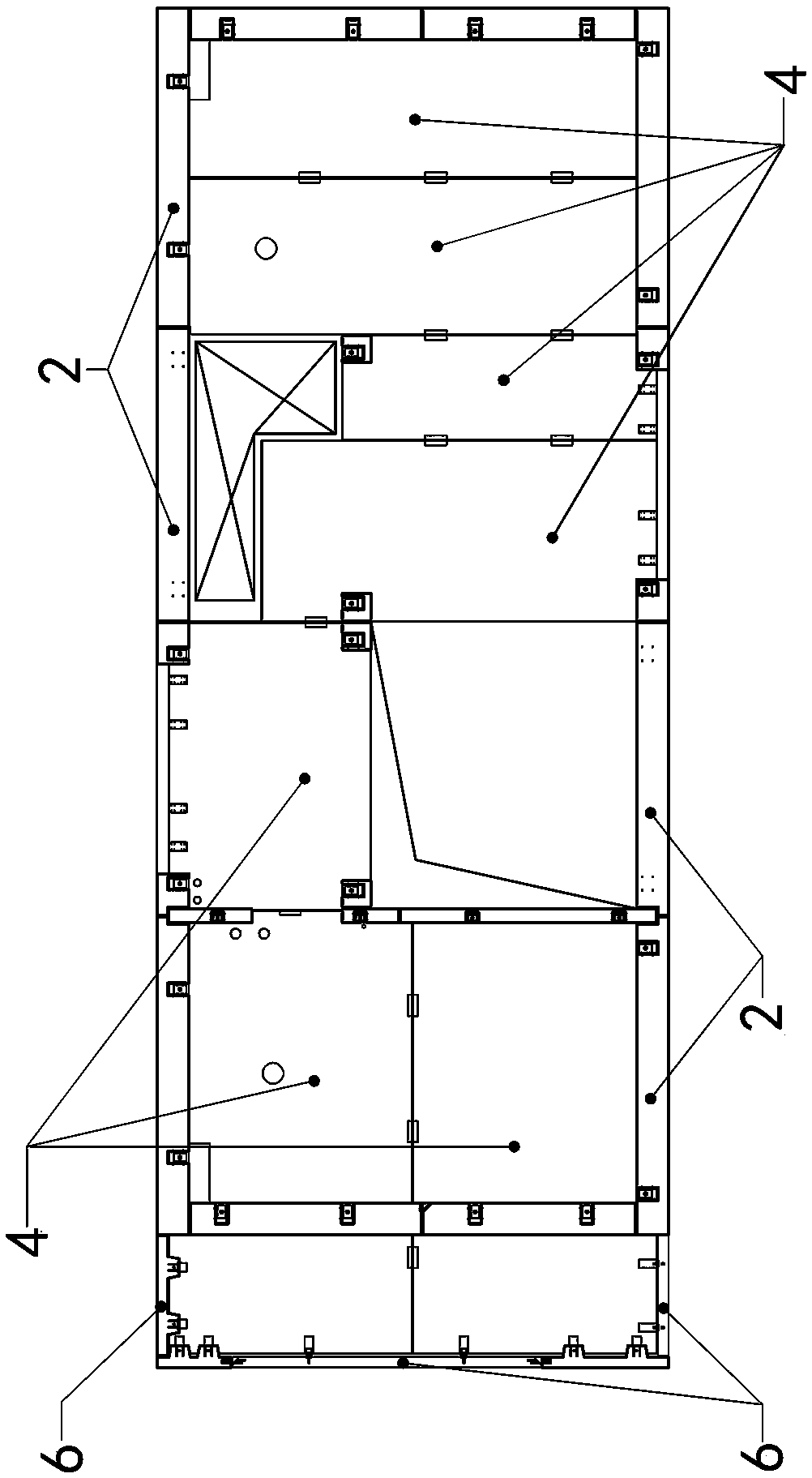

[0062] Examples see figure 1 , 2 , 3, 4, 5 and 6, it is a two-storey residential structure, using a dry-connected panel structure system, including structural foundation 1, vertical members of each floor and horizontal members of each floor, and the vertical members include prefabricated Shear wall panels and prefabricated external cladding panels 6, the horizontal member includes a prefabricated floor slab 4; the prefabricated shear wall panels include a prefabricated exterior wall panel 2 and a prefabricated interior wall panel 3, and also include a prefabricated floor slab with the top floor, a prefabricated floor slab on the top floor Prefabricated parapet 5 with fixed connection of shear wall panels.

[0063] In this residential structure, the vertical connections between the structural foundation 1 and the vertical components or between adjacent vertical components are all connected as a whole through dry vertical connection structures. The schematic diagram of the thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com