Slope rock riverbed steel cofferdam based on suspended corner processing structures

A technology of steel cofferdam and slope rock, applied in the field of steel cofferdam, can solve the problems of difficult construction of cofferdam bottom sealing concrete, inability to implement leakage plugging outside the cofferdam, increased workload of foundation pit excavation, etc., and achieves high practical value. , The effect of reducing the amount of excavation of the foundation pit and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

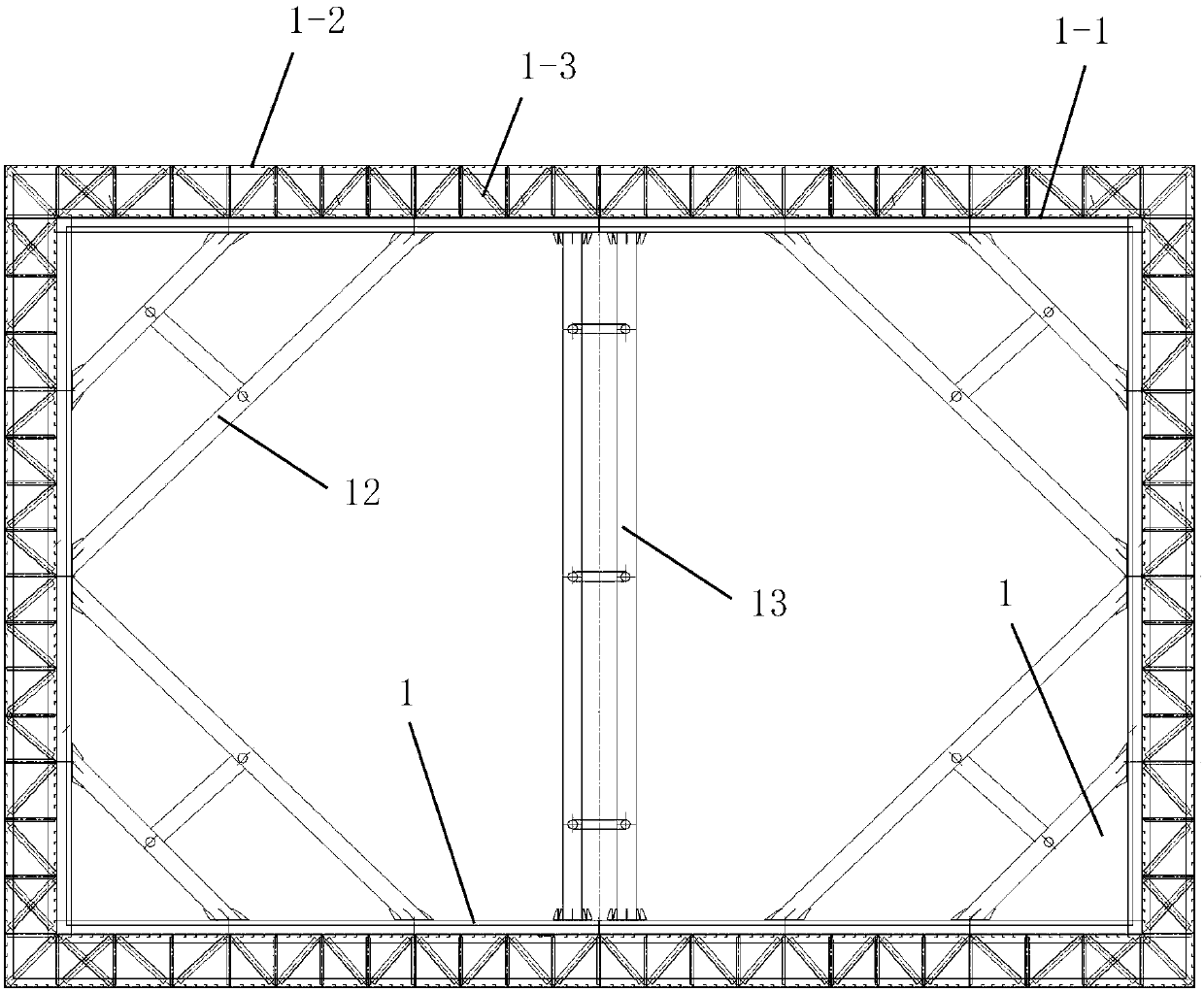

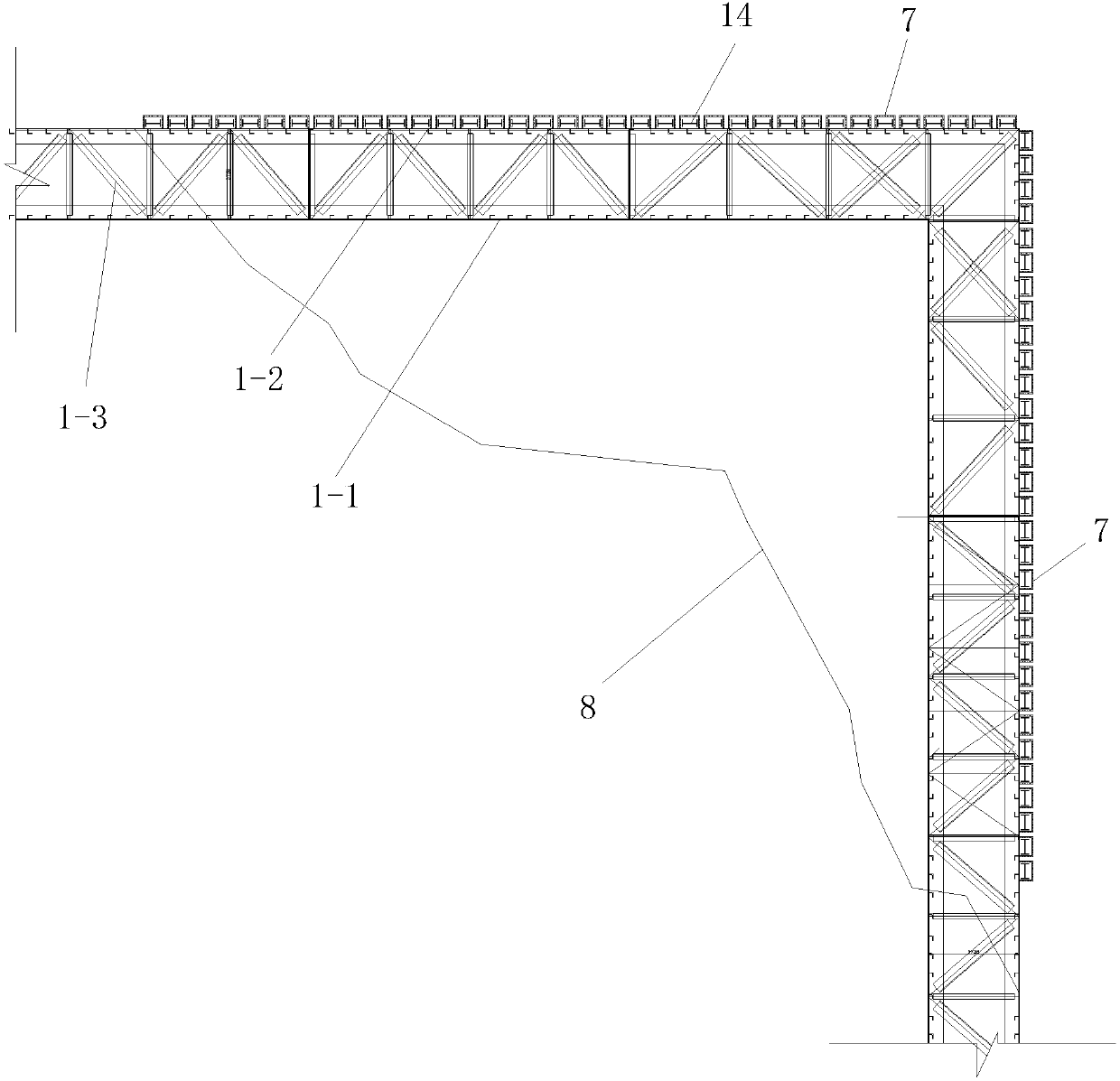

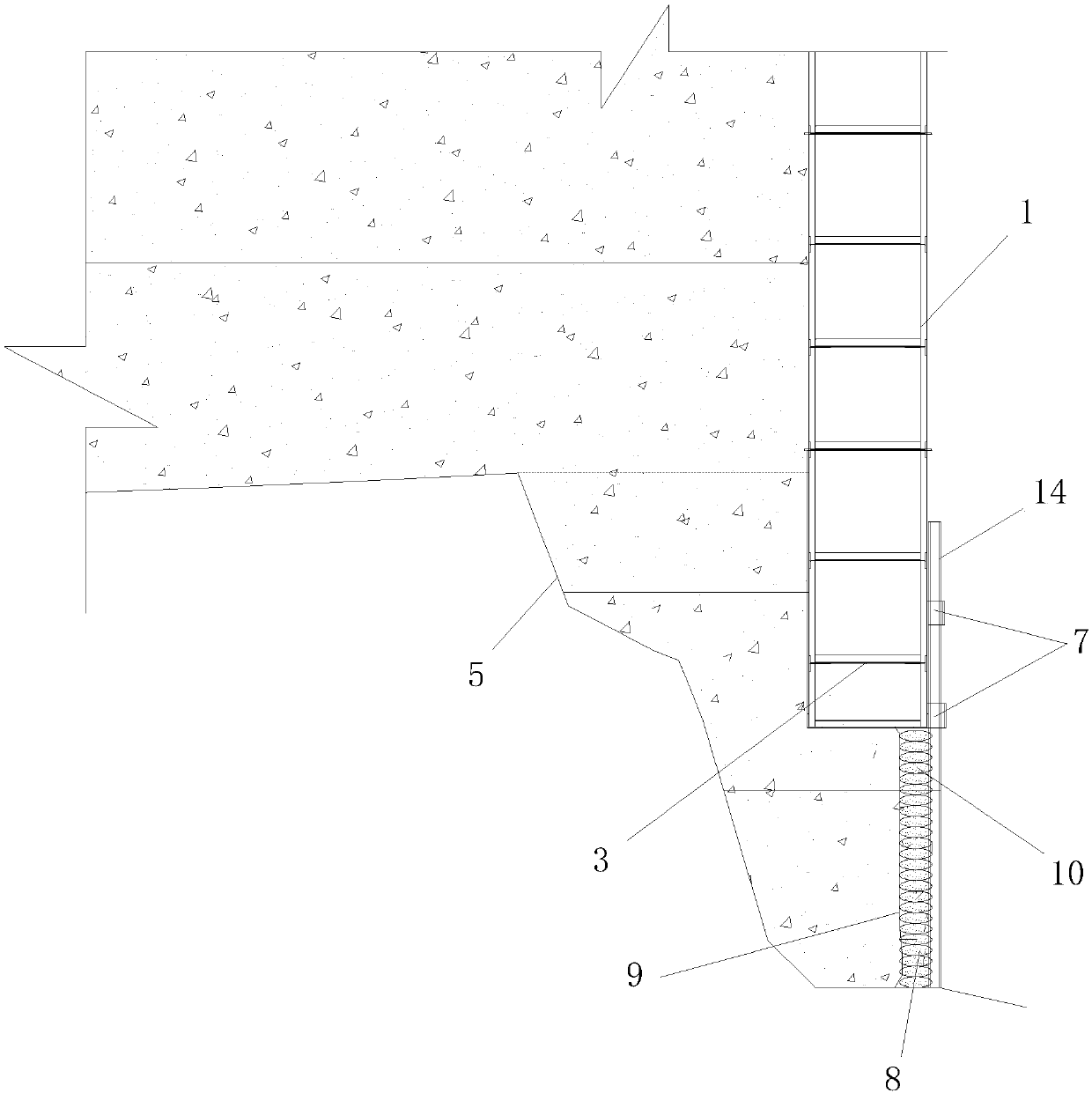

[0040] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the present invention includes a steel cofferdam body 1 and a suspension foot processing structure arranged on the suspension feet of the steel cofferdam body 1, and the steel cofferdam body 1 is a cubic steel sleeve supported on the slope rock riverbed 5 box, the cross-section of the cubic steel box is rectangular; the steel cofferdam body 1 is arranged vertically and it is spliced by four cofferdam panels all arranged vertically; The feet are the top corners suspended at the bottom of the steel cofferdam body 1, and the number of the suspended suspension feet processing structure is the same as the number of the suspended suspension feet; the suspension suspension feet processing structure includes two suspended wall panels arranged vertically The processing structure, each of the suspended wall panel processing structures includes one or more suspended wall panel segment processing stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com