An elevator shaft frame and its installation method

An elevator shaft and frame technology, which is applied to elevators, transportation and packaging, elevators, etc. in buildings, can solve problems such as high cost and difficult elevator installation, reduce installation difficulty, simplify overall aesthetics, and improve overall aesthetics sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

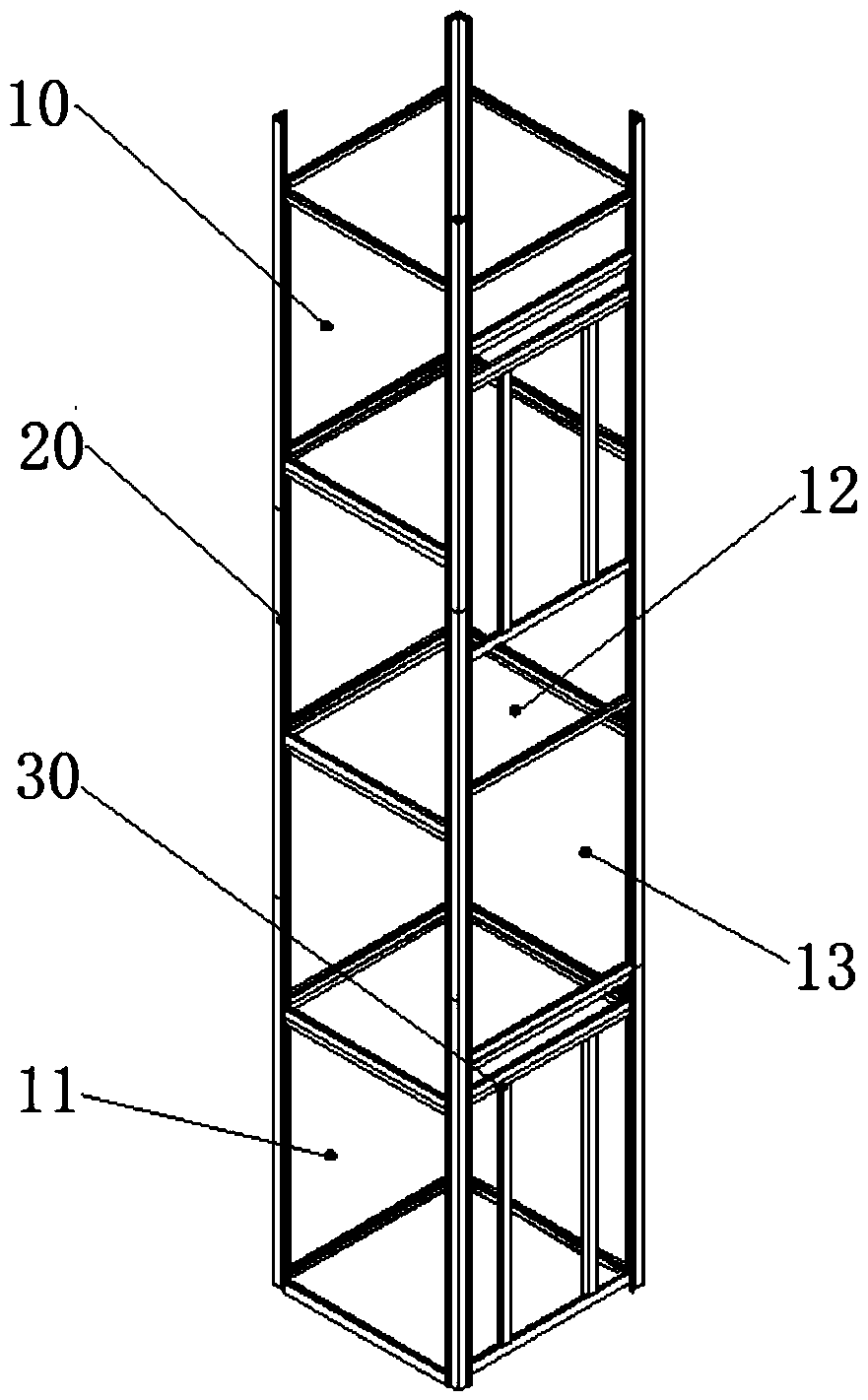

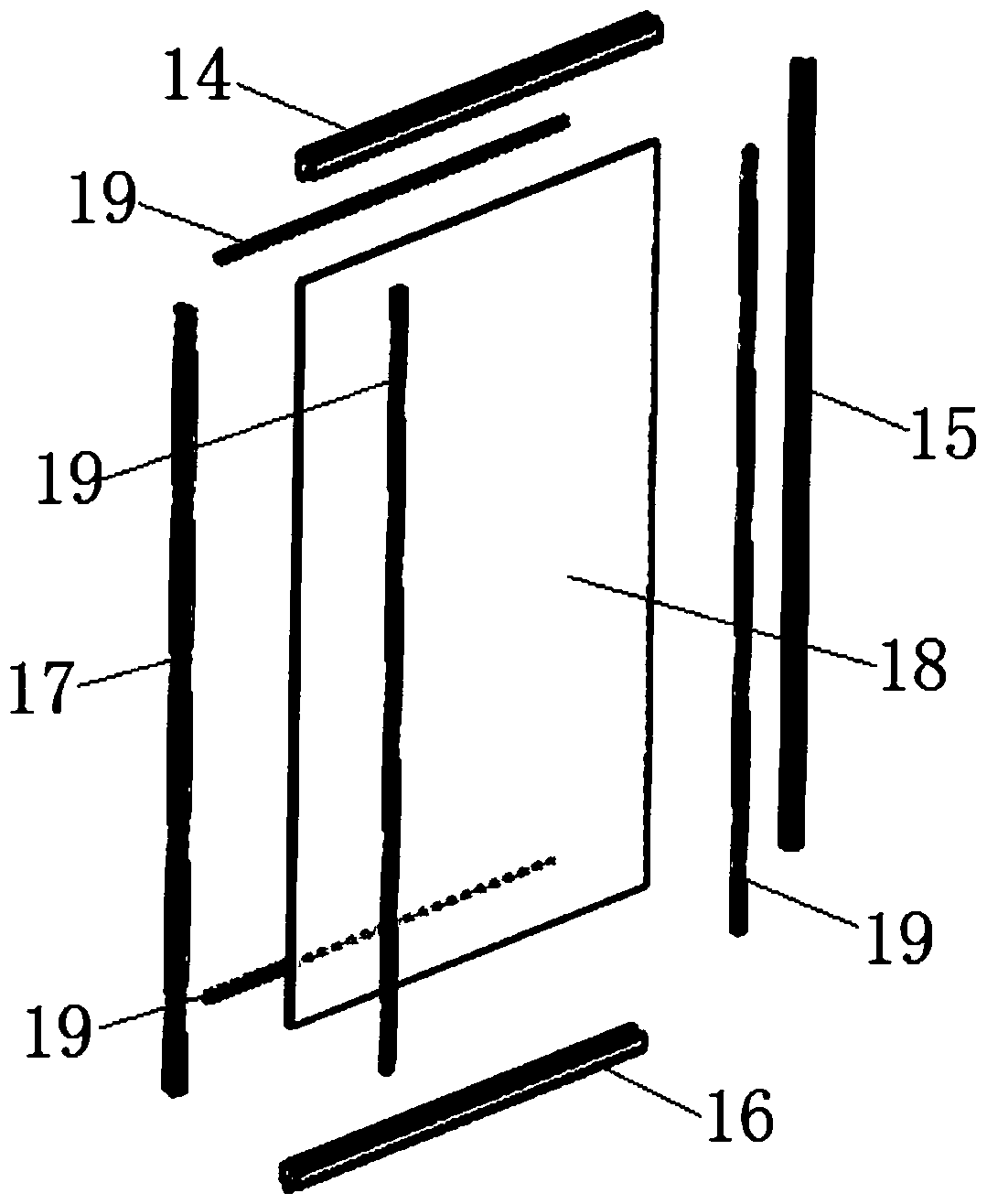

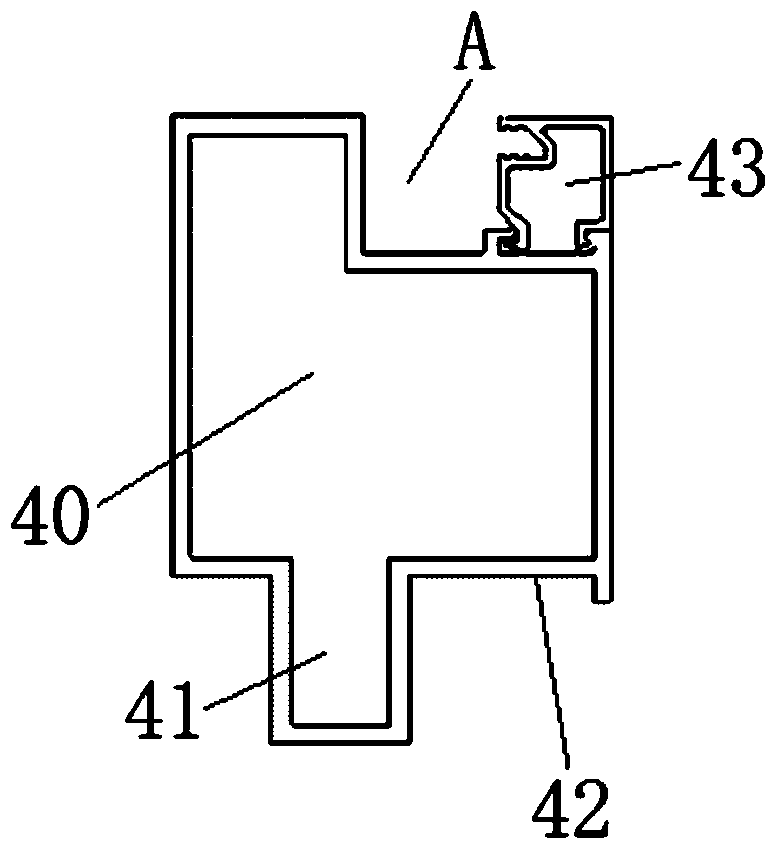

[0032] Such as Figure 1 to Figure 7 As shown, the present invention provides an elevator hoistway frame, including a plurality of door area modules 30, a plurality of hoistway wall modules 10, and a column structure; the column structure forms a square hoistway frame through four columns 20 in the longitudinal direction, specifically including a square The hoistway frame is formed by stacking a plurality of small modular quadrilateral frames, which is convenient for assembly and has better overall performance; a plurality of hoistway wall modules 10 are connected in sequence to form a closed space; the hoistway wall modules 10 are arranged between the columns 20; the door The area module 30 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com