Unloading auxiliary mechanism of powder pigment carrying vehicle for shoe making

A technology of auxiliary mechanism and transport vehicle, which is applied in the direction of freight vehicles, motor vehicles, transport objects, etc. It can solve the problems of affecting the operating environment sanitation, powder spillage, and health damage of operators, so as to avoid powder spillage and damage , the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

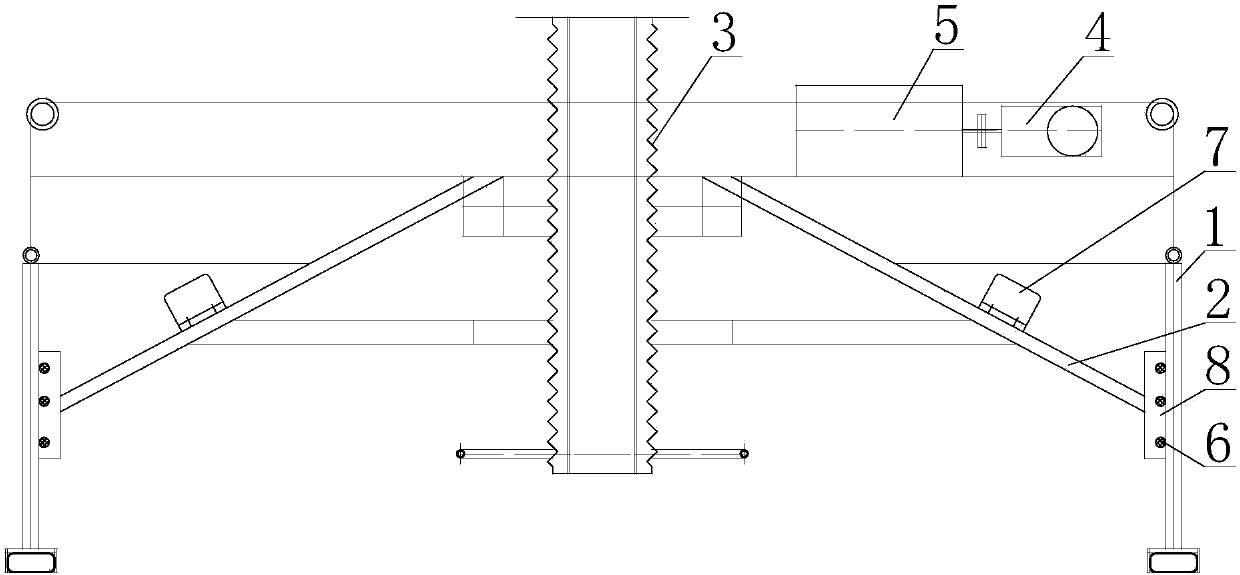

[0015] Such as figure 1 As shown, the unloading auxiliary mechanism of the powder paint truck for shoemaking includes an outer cover 1, an inner cover 2, a discharge cylinder 3 and an outer cover lifting drive mechanism, wherein the outer cover 1 forms a square shape, and its The lower end is open, the inner cover 2 is arranged in the outer cover 1 and forms a cone shape, the inner wall of the outer cover 1 is connected with a rectangular frame-shaped adapter plate 8, and the lower end of the side wall of the inner cover 2 is connected to the adapter plate 8 The top is connected with the outer cover 1, and then the lower end of the inner cover 2 is sealed and connected to the inner wall of the outer cover 1. In order to improve the sealing performance between the outer cover 1 and the adapter plate 8 , a plurality of sealing rings 6 are arranged between the adapter plate 8 and the outer cover 1 . The top of the inner cover 2 is formed with a circular opening, one end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com