Soybean product press filter device

A soy product and filter chamber technology, applied in dairy products, milk substitutes, presses, etc., can solve the problems of inability to perform continuous filtration, low efficiency, and high labor intensity of workers, and achieve continuous production, reduce labor intensity, and efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

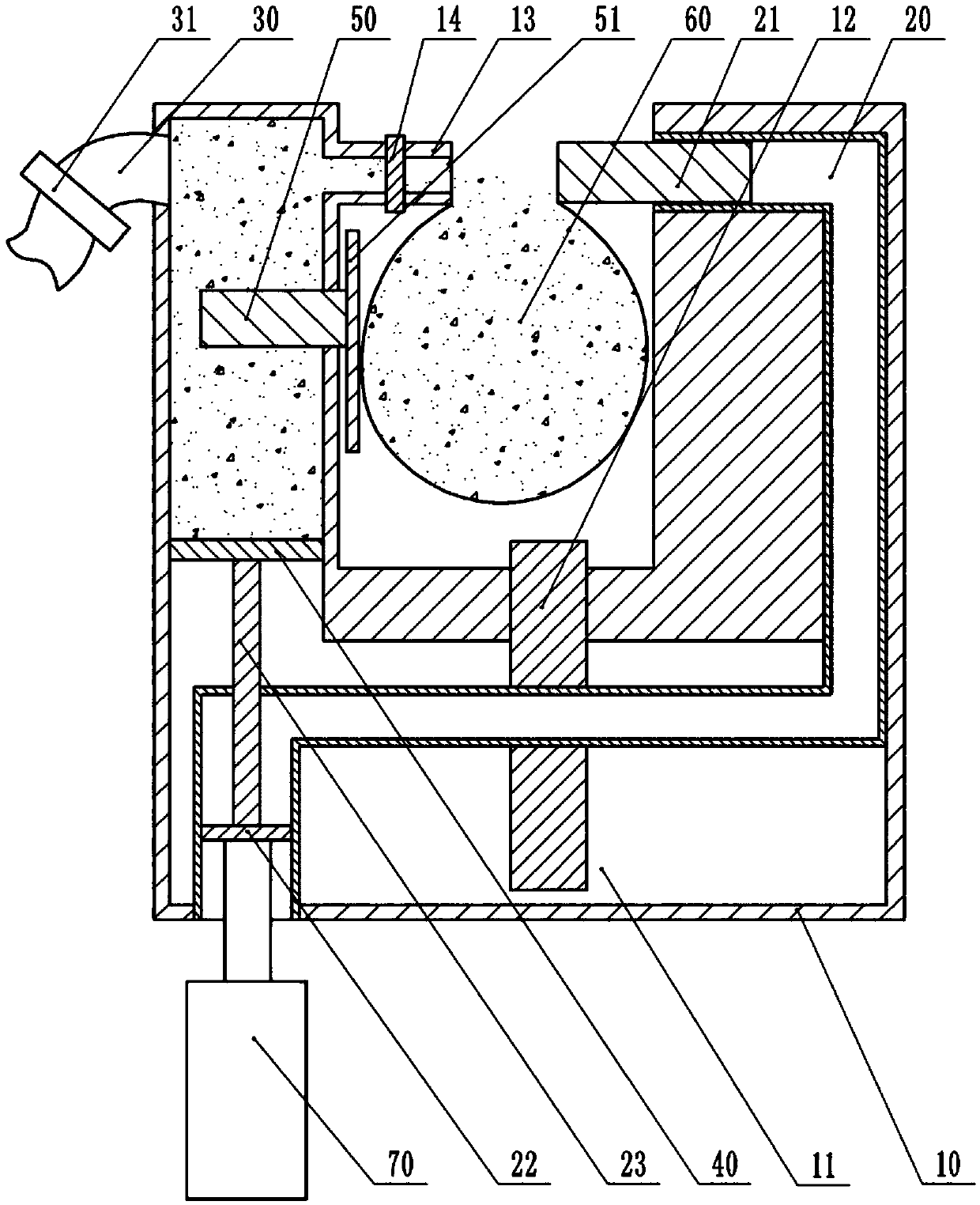

[0024] Such as figure 1 As shown, the bean product press filter device includes a transfer unit, a power unit, a filter press chamber 10 and a filter bag 60, the upper surface of the filter press chamber 10 has a groove, and the filter bag 60 is installed in the groove. The bottom of the filter chamber 10 and the side wall on one side are provided with a cavity 11 communicating with each other, and the side wall of the filter chamber 10 is provided with a discharge pipe 13 and a pressure column for squeezing the filter bag 60 sequentially from top to bottom. 50, the discharge pipe 13 communicates with the cavity 11, and the outlet of the discharge pipe 13 is located in the groove; the discharge pipe 13 is provided with a first check valve 14, when the pressure in the cavity 11 on the side wall of the filter chamber 10 increases , the first one-way valve 14 can be opened automatically. The pressure column 50 is slidably connected to the side wall of the filter chamber 10, one ...

Embodiment 2

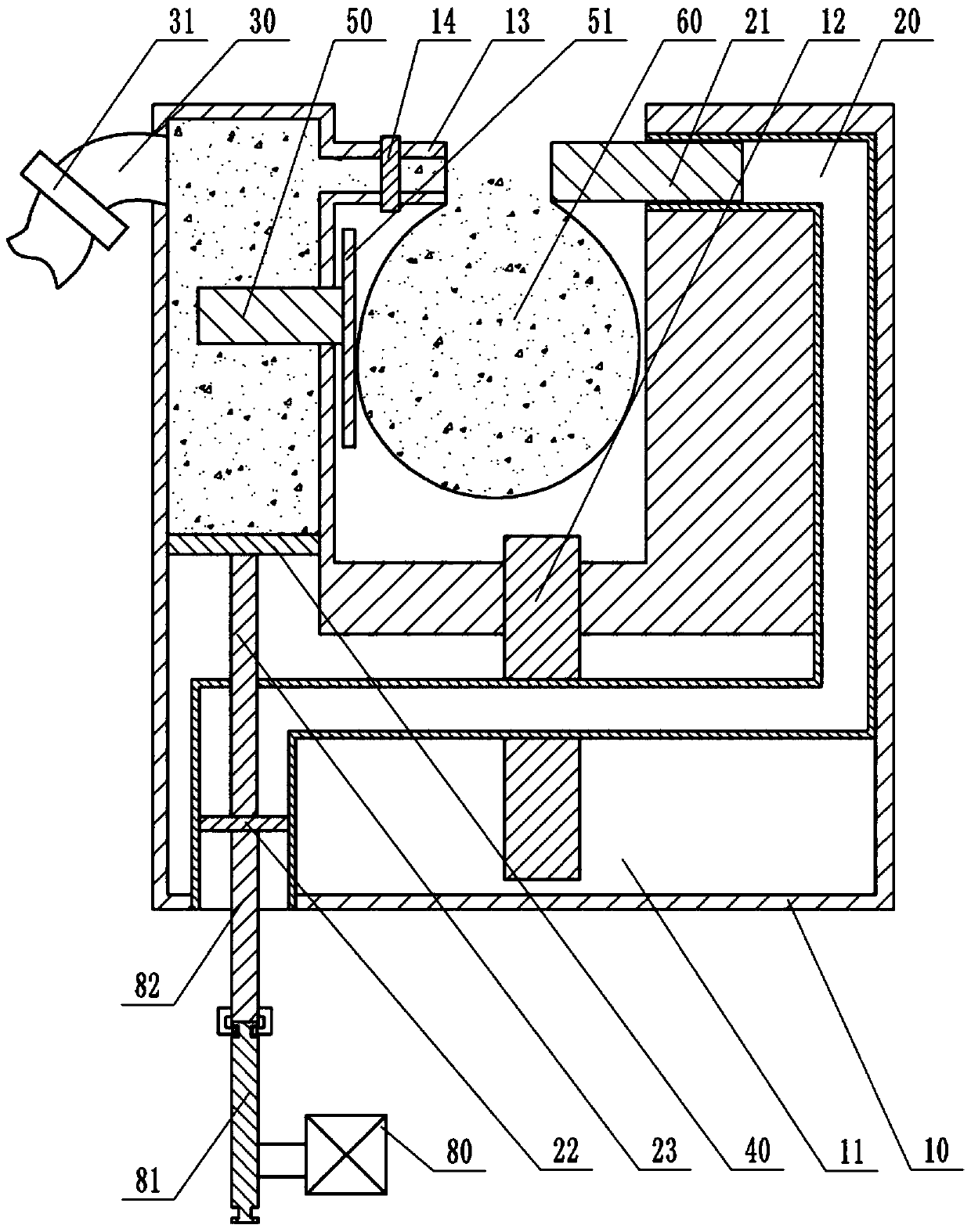

[0028] The difference between this implementation and embodiment 1 is: as figure 2 As shown, the power unit in this implementation includes a cam 81, a push rod 82 and a motor 80, the output shaft of the motor 80 is fixed on the surface of the cam 81, and the motor 80 can drive the cam 81 to rotate. Both sides of the cam 81 are provided with an annular groove consistent with the contour of the cam 81; one end of the push rod 82 is hinged on the pressure plate 22, and the other end is provided with a roller engaged with the annular groove. The motor 80 drives the cam 81 to rotate. During the rotation of the cam 81, the cam 81 can drive the push rod 82 to reciprocate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com