Supported micropore-mesopore composite molecular sieve membrane and preparation method thereof

A composite molecular sieve and molecular sieve membrane technology, applied in molecular sieve catalysts, chemical instruments and methods, organic carbonate preparation, etc., can solve the problems of poor hydrothermal stability and low equilibrium conversion rate of mesoporous materials, and achieve improved equilibrium conversion rate, The effect of enhancing hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

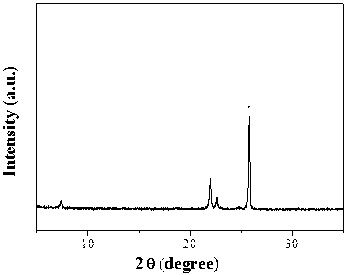

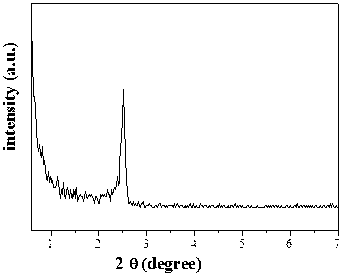

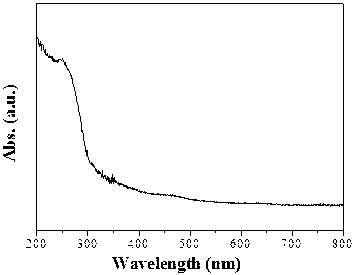

Image

Examples

Embodiment 1

[0019] Preparation of TS-1 microporous precursor solution: Add 14.013g tetrapropylammonium hydroxide (TPAOH) (10.676wt%) and 12.026g water into a three-neck flask, stir vigorously for 20min; slowly add 5.676g ethyl orthosilicate ( TEOS) was vigorously stirred for 3 hours until clarified to obtain a silicon-containing clear liquid; 0.3091 g of tetrabutyl titanate was dissolved in 1.326 g of isopropyl

[0020] Alcohol to obtain titanium-containing isopropanol solution, in ice-salt bath and N 2 Add the obtained titanium-containing isopropanol solution dropwise into the silicon-containing clear solution under protection and slow stirring. After about 1 hour, remove the isopropanol at a constant temperature in a water bath at 80°C for about 0.5 hours, and evaporate to remove the isopropanol. After adding deionized water to the original volume, the molar ratio obtained is SiO 2 : TiO 2 : TPAOH: H 2 O=1:0.033:0.27:50 clear microporous structure synthesis liquid; then transfer the ...

Embodiment 2

[0023] The preparation of TS-1 microporous precursor solution was the same as in Example 1. In the synthesis steps of Ti-HMS-1 molecular sieve membrane, except that the crystallization temperature was 100 °C and the crystallization time was 96 h, the rest were the same as in Example 1.

Embodiment 3

[0025] In the preparation steps of the TS-1 microporous precursor solution, except that the amount of tetrapropylammonium hydroxide (10.676%) was 10.4g, and the amount of ionized water was 15.3g, the rest were the same as in Example 1.

[0026] In the synthesis steps of Ti-HMS-1 molecular sieve membrane, except that the dosage of mesoporous template DDA is 1g, the dosage of TS-1 microporous precursor solution is 25ml, the crystallization temperature is 160℃, and the crystallization time is 36h, the rest are Same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com