Tea steaming barrel

A technology for steaming a tea barrel and a barrel body is applied in the field of steaming tea barrels, which can solve the problems of high labor intensity and low work efficiency, and achieve the effects of saving labor, improving work efficiency and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

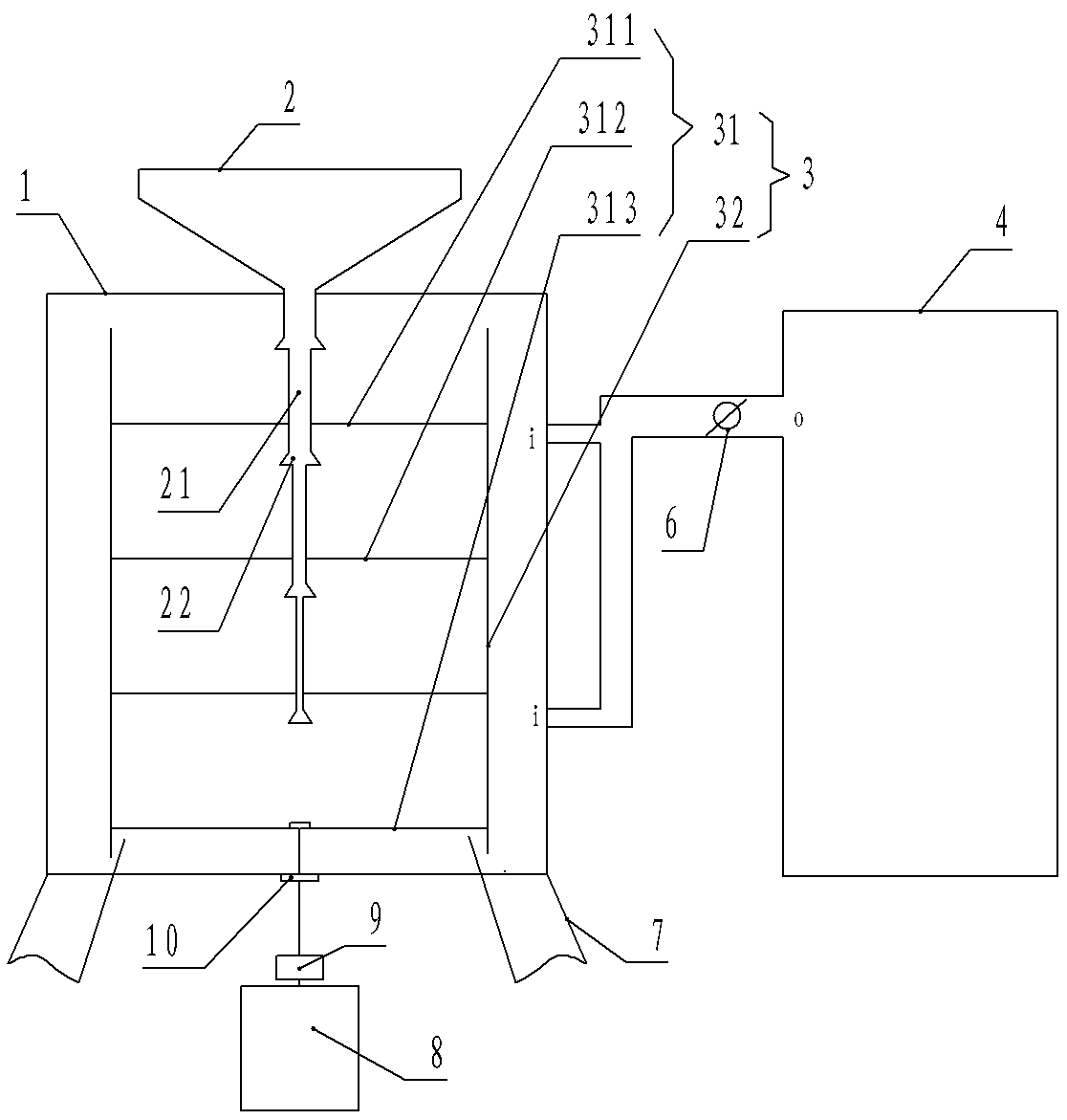

[0014] figure 1 The steamed tea barrel shown includes a barrel body 1, and a steam inlet i is opened on the side wall of the barrel body 1, and the steam inlet i communicates with the steam outlet 0 of a steam generator 4; communicates with the steam outlet 0 A valve 6 is provided on the outlet pipe of the barrel body 1; a steaming frame 3 is provided in the barrel body 1, and the steaming frame 3 includes four vertical support rods 32 and a mesh plate 31 arranged between these support rods 32, and the mesh plate 31 is arranged from above. There are three layers of upper net plate 311, middle net plate 312, and lower net plate 313 downwards; a motor 8 is arranged below the barrel body 1, and a bearing hole of the motor 8 is provided on the bottom plate of the barrel body 1, and the bearing 10 is installed on the bottom plate of the barrel body 1. In th...

Embodiment 2

[0017] The screen plate 31 has four layers from top to bottom; the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com