Composite suspension type silicon rubber insulator structure

A silicone rubber insulation and substructure technology, applied in the direction of suspension/strain insulators, insulators, electrical components, etc., can solve problems such as high-voltage leakage, limitation, and insulator creepage distance limitation, so as to improve insulation ability, prevent breakdown and conduction, Improved stability and resistance to lateral tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

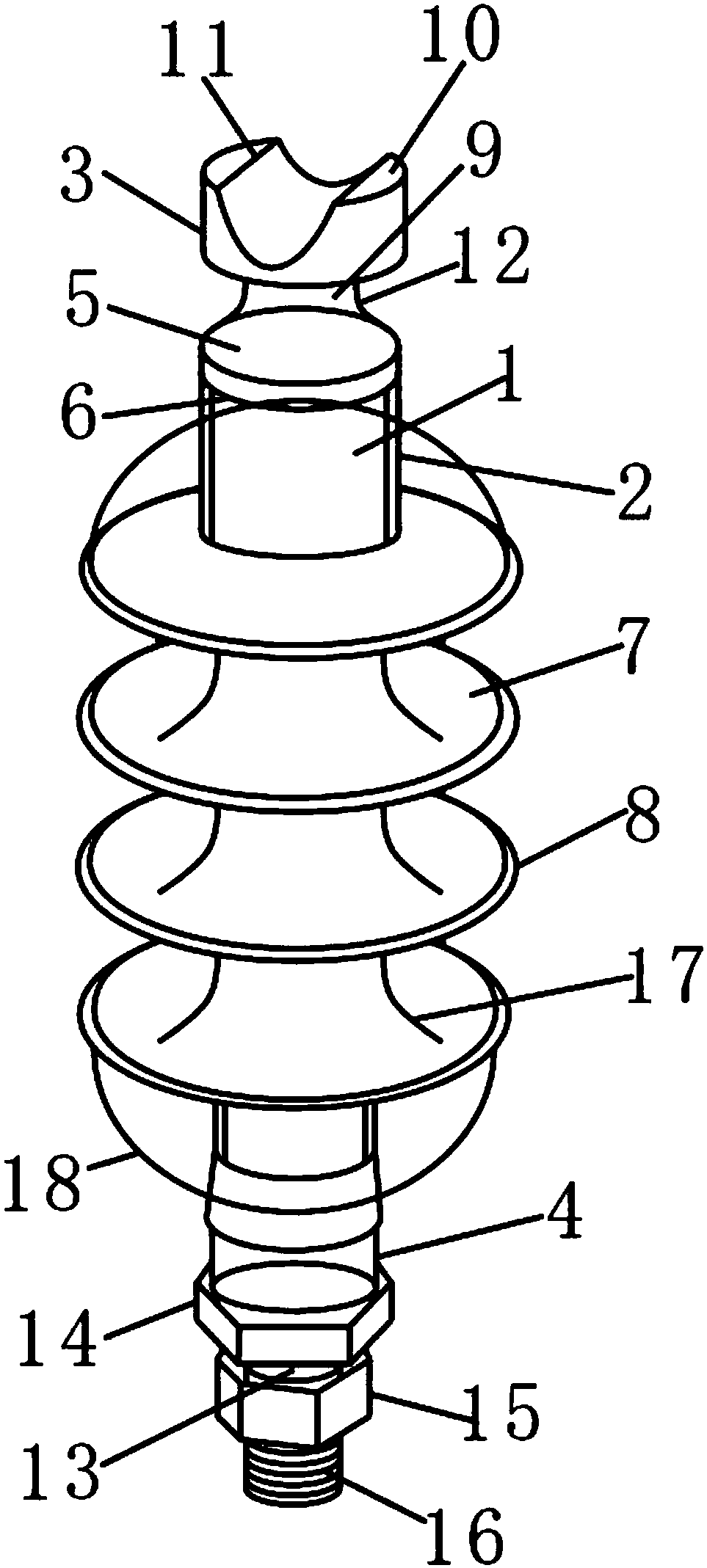

[0022] Such as figure 1 As shown, the present invention provides a composite suspension silicone rubber insulator structure, including a support core 1 and a composite jacket 2, and the two ends of the support core 1 are respectively fixedly installed with a winding binding head 3 and an installation base 4. The winding and binding head 3 is made of glass fiber epoxy resin ceramics, the composite jacket 2 is made of silicon rubber, and the composite jacket 2 is coated on the outer surface of the support core 1, and the support core 1 and the winding and binding head 3 And the connection of the installation base frame 4 is provided with an annular protrusion 5, and the outer surface of the annular protrusion 5 is coated with a silicone rubber ring sleeve 6, and the outer surface of the support core 1 is coated with a composite outer jacket 2, To form an insulation protection effect, and the ring-shaped protrusions 5 are provided at the joints of both ends, and the silicone rubb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com