System and method for testing surface quality of Wolter-I--type mandrel by adopting contact-type contourgraph

A testing system and surface quality technology, applied in the field of ultra-precision measurement, can solve the problems of not finding reference vertices, difficult to inspect the surface quality of mandrels, etc., to avoid the effect of long measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

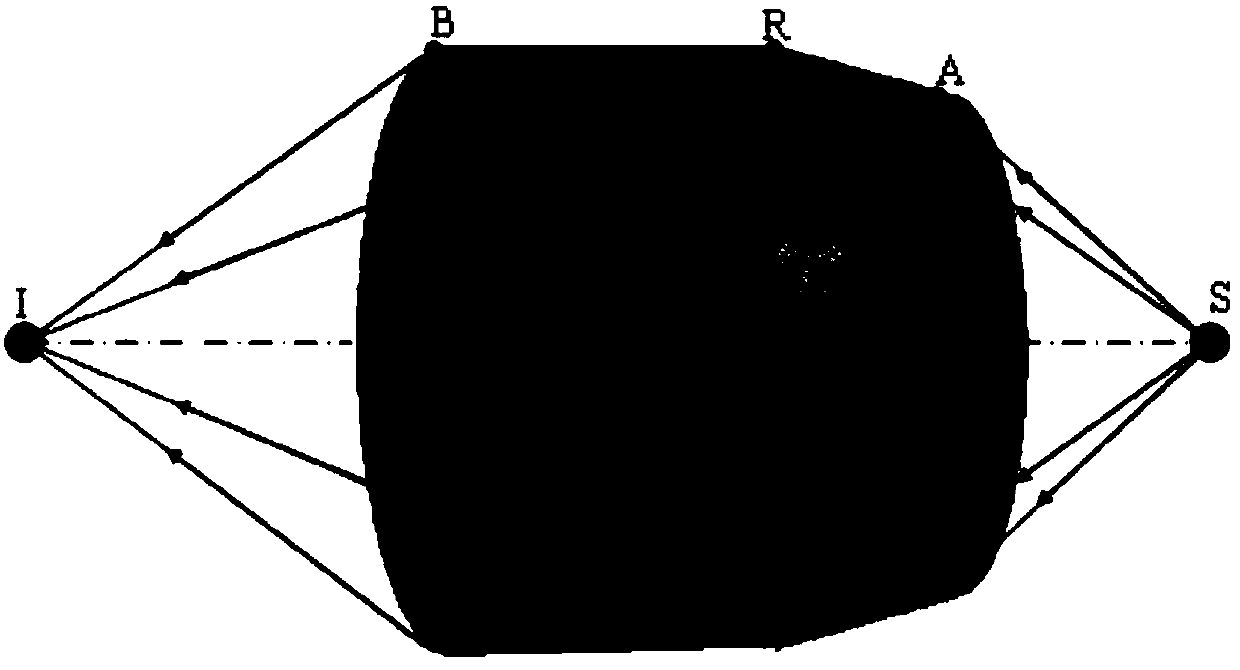

[0045] Embodiment 1: This embodiment provides a method for testing the surface quality of a Wolter-I mandrel using a contact profiler. The specific implementation steps are as follows:

[0046] 1. Build a measurement system

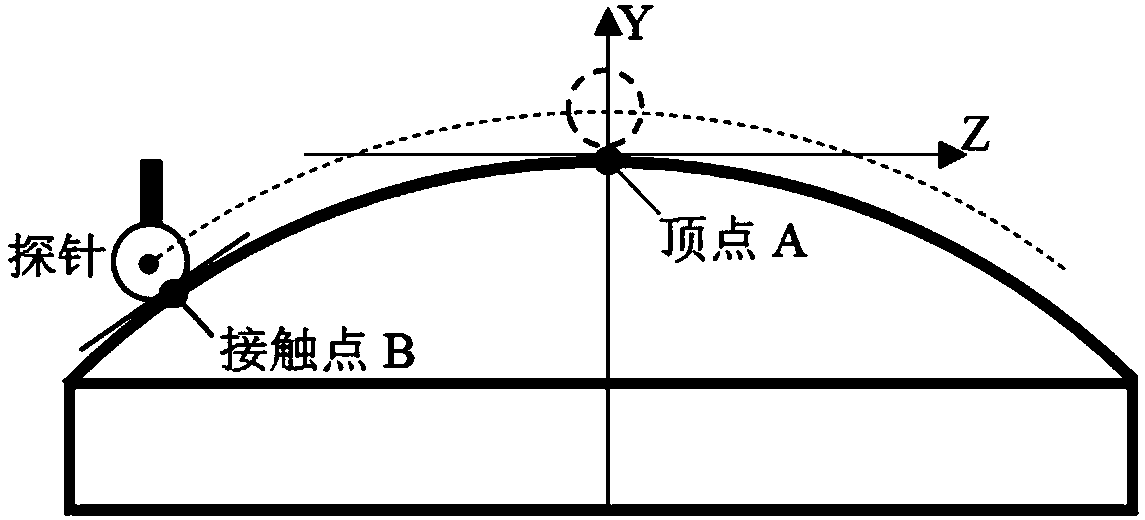

[0047] In order to ensure the accuracy of the measurement of the axisymmetric aspheric surface by the contact profiler, the probe of the profiler must move along the meridian section profile curve of the aspheric surface. Therefore, it is necessary to design an auxiliary adjustment device to precisely adjust the relative position between the mandrel and the probe. The auxiliary adjustment device includes an X-axis linear displacement table 3, a horizontal rotary table 2, a vertical surface rotary table 1, and a chuck 5 for clamping workpieces. Among them, the X-axis linear displacement table 3 is fixedly installed on the table surface of the profiler detection platform, and its motion direction is perpendicular to the motion direction of the probe 6, and...

specific Embodiment approach 2

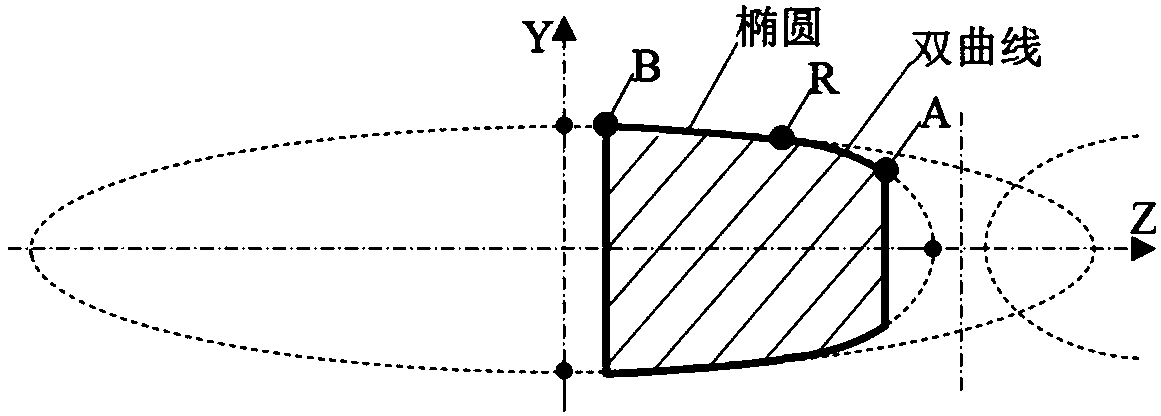

[0062] Specific embodiment two: the Woler I type mandrel used in the experiment in this embodiment is made of ellipsoidal surface and hyperboloid, analyze and calculate with the inspection of ellipsoidal surface quality as example, draw its performance index, hyperboloid surface quality inspection The method of analysis and calculation is the same as that of the ellipsoid. It is known that the diameters corresponding to points R and B on the ellipsoid are d R =150.4872mm and d B =153.4338mm, axial distance L RB =101.3474mm, such as image 3 shown. A probe with a radius of 2 μm was selected, and the sampling interval was set to 1 μm, and the measurement experiment was carried out on the mandrel after ultra-precision turning. Starting from point R, take 70,000 measurement points on the meridian section curve of the ellipsoid for analysis, corresponding to a measurement length of 70mm, and the measurement results are as follows:

[0063] 1) Mandrel radial size error (diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com