Foundation pit with first support zone having dynamic stress regulation function and construction method of foundation pit

A technology of dynamic stress and stress adjustment, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of inability to control and intervene in dangerous situations, sacrificing the surrounding environment, and inability to apply, and achieve good application prospects, good economy, and expansion of construction methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

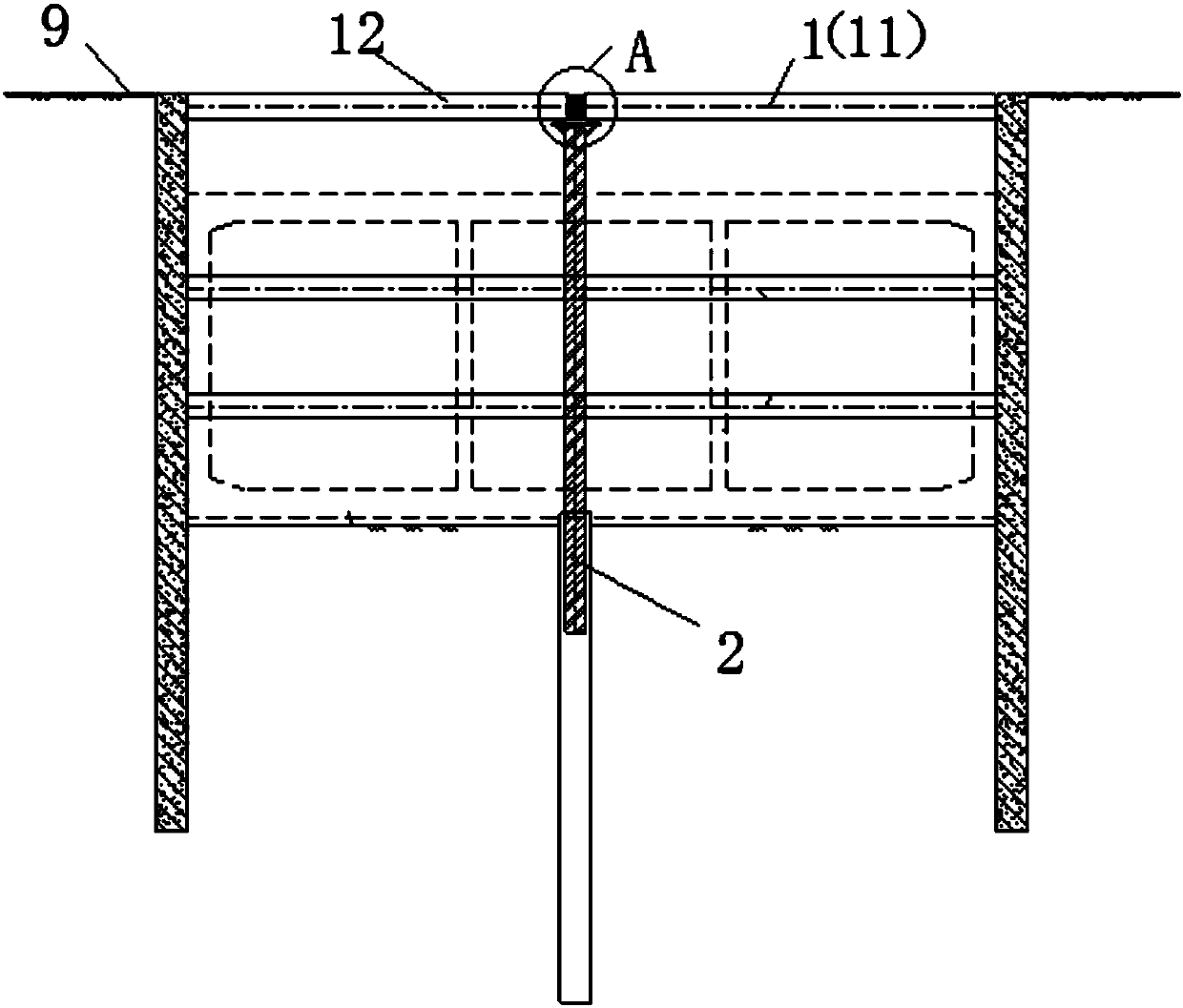

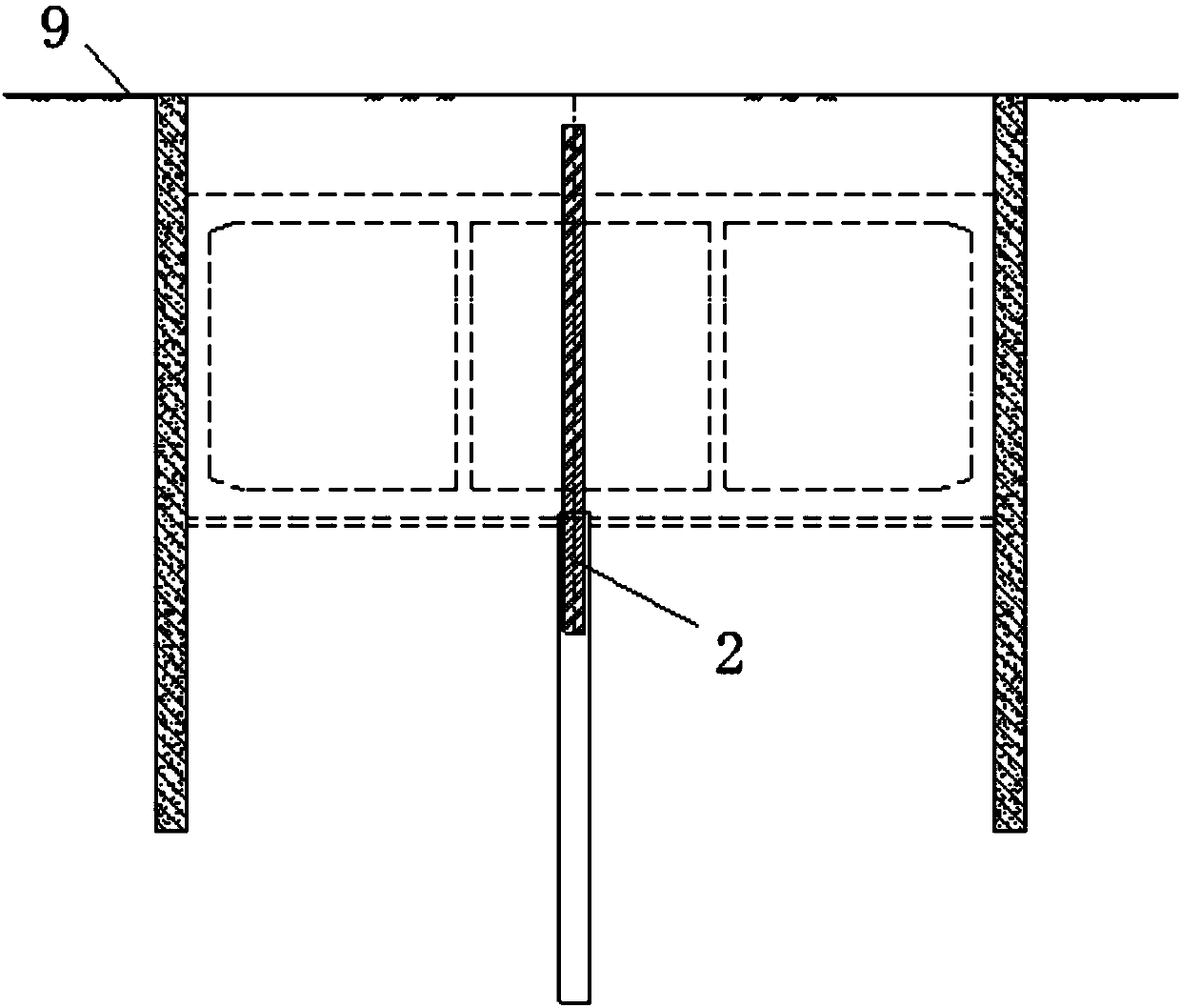

[0038] like figure 1 and figure 2 As shown, the foundation pit with the dynamic stress adjustment function of the first support includes the first support 1 located at the connection between the foundation pit and the ground 9 .

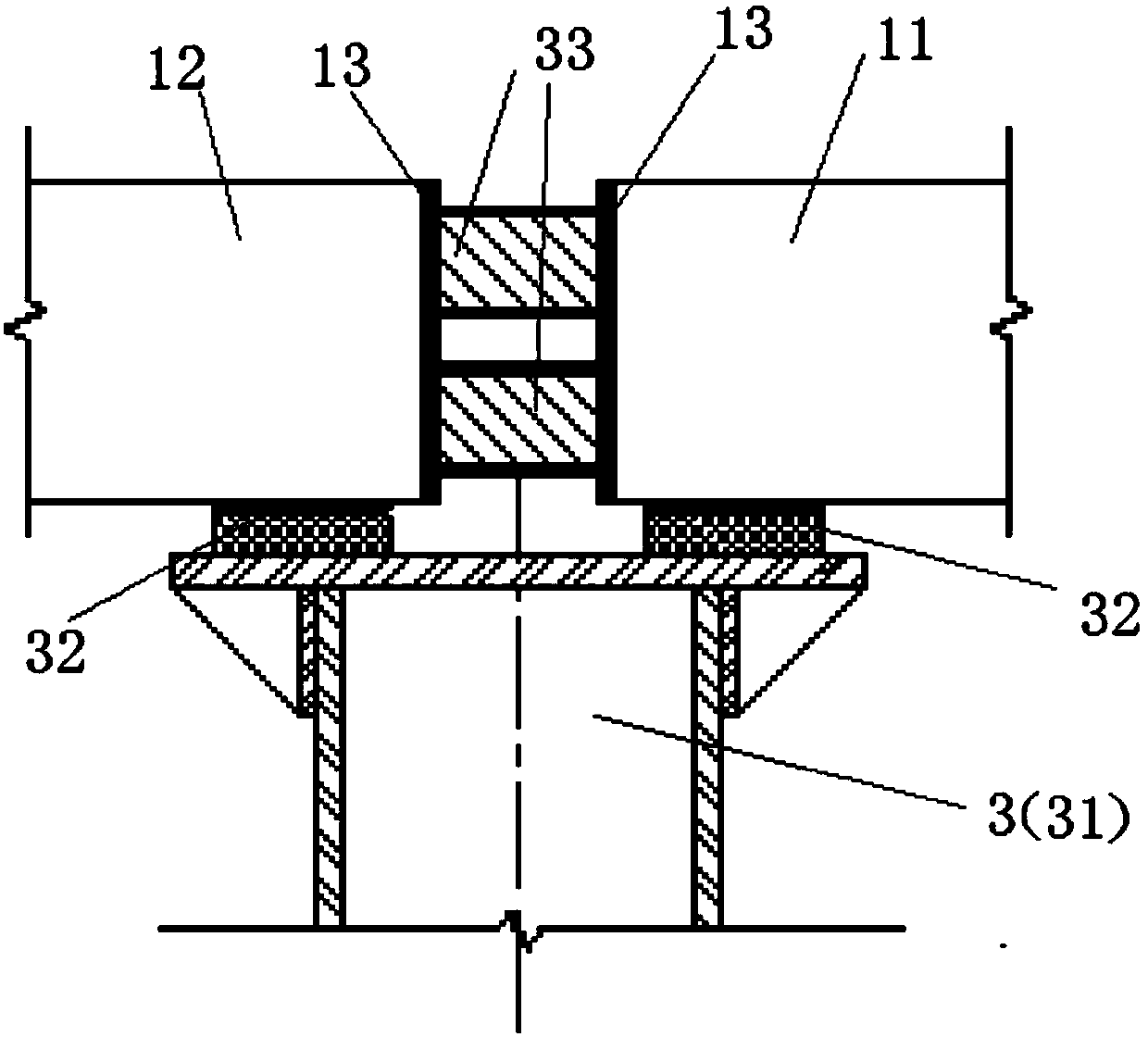

[0039] The first support 1 is disconnected near the middle to form a left half support 12 and a right half support 11, and a stress adjustment device 3 is arranged between the left half support 12 and the right half support 11.

[0040] The stress adjusting device 3 is fixed in the foundation pit by means of a steel column 2 vertically arranged in the foundation pit.

[0041] The stress adjusting device 3 includes a jacking plate 31 , a slide support 32 and a jack 33 .

[0042] The top supporting plate 31 includes a connection portion fixedly connected to the upper end of the steel column 2, and a supporting plate perpendicular to the steel column and extending in a plate shape around the periphery. The center of the supporting plate is located di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com