Subway station damping beam column joint with high durability and construction method thereof

A technology for subway stations and seismic beams and columns, which is used in earthquake prevention, artificial islands, water conservancy projects, etc., can solve the problems of unconsidered shock absorbers and difficult durability, so as to improve shear deformation resistance and avoid shear compression damage. , the effect of good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

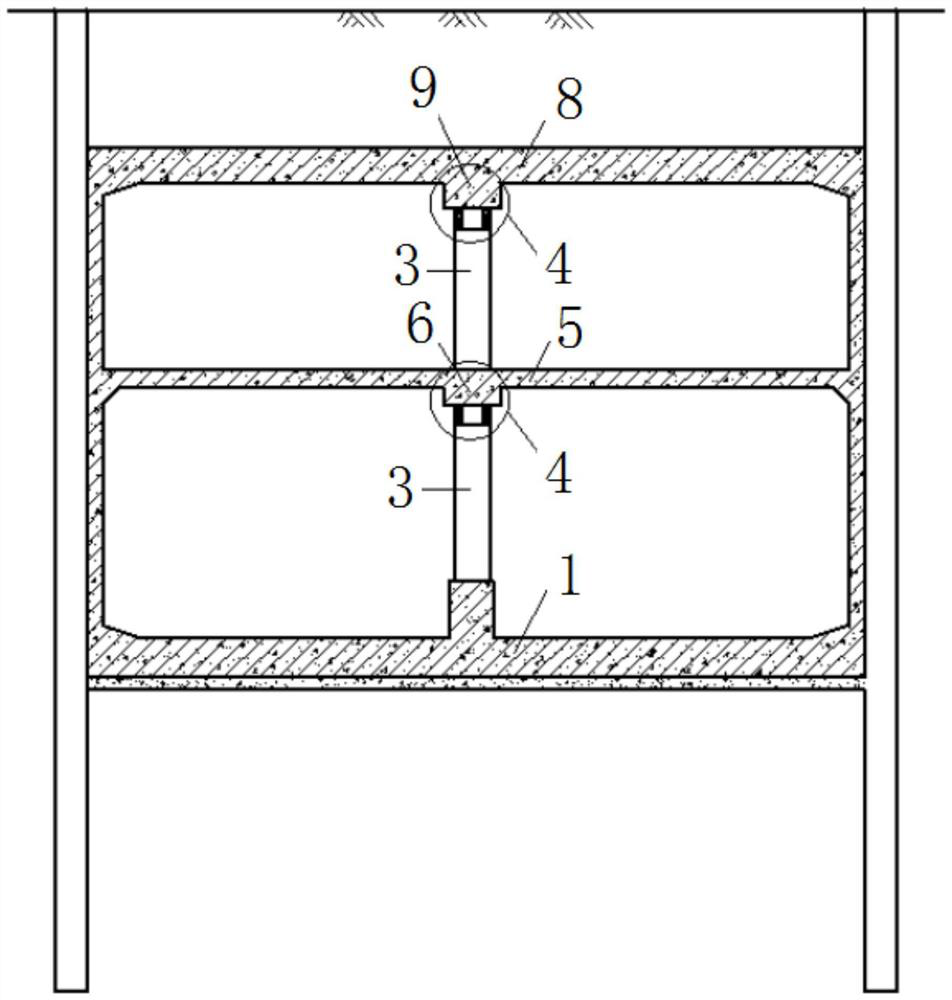

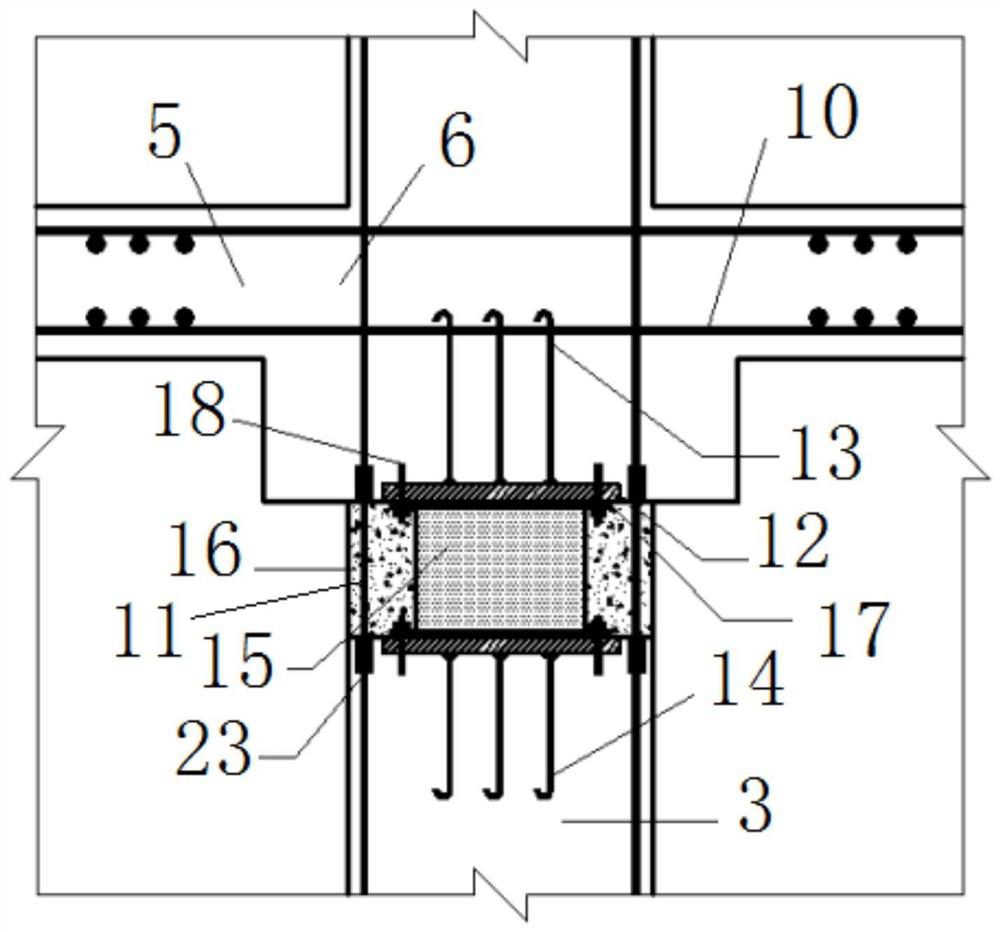

[0045] Such as Figure 1 to Figure 5 As shown, taking into account the high-durability subway station shock-absorbing beam-column nodes, the shock-absorbing beam-column nodes 4 are set between the column end of each middle column 3 and the corresponding top longitudinal beam 9 of the subway station, and the corresponding middle longitudinal beam 6 between;

[0046] Each shock-absorbing beam-column node 4 includes a matching elastic bearing connection system and elastic bearing 15, as well as a protective structure;

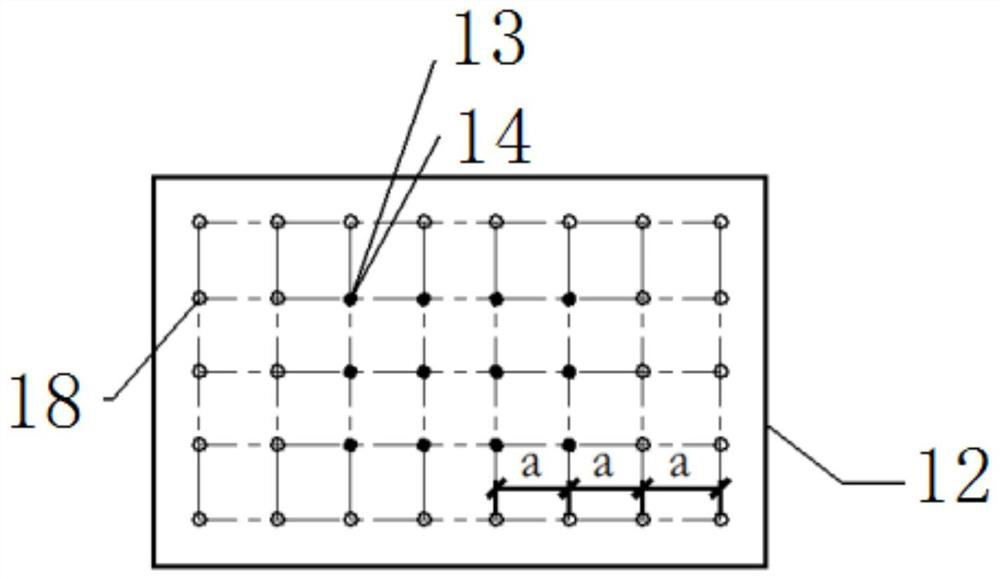

[0047] Each elastic support connection system includes steel bar connectors 23, embedded steel plates 12, embedded column anchor bars 14 and embedded anchor bolts 18 arranged at the ends of the corresponding middle columns 3, and installed on the corresponding top longitudinal beams. 9 or the corresponding steel bar connector 23 at the bottom of the longitudinal beam 6, the embedded steel plate 12, the embedded beam anchor bar 13 and the embedded anchor bolt 18; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com