Variable cross-section drilling pouring support pile structure and construction method thereof

A technology for drilling and pouring and supporting piles, which is applied in basic structure engineering, excavation, sheet pile walls, etc., can solve problems such as waste of supporting structures, and achieves expansion of construction means, good economy, and reduction of supporting structure engineering quantities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

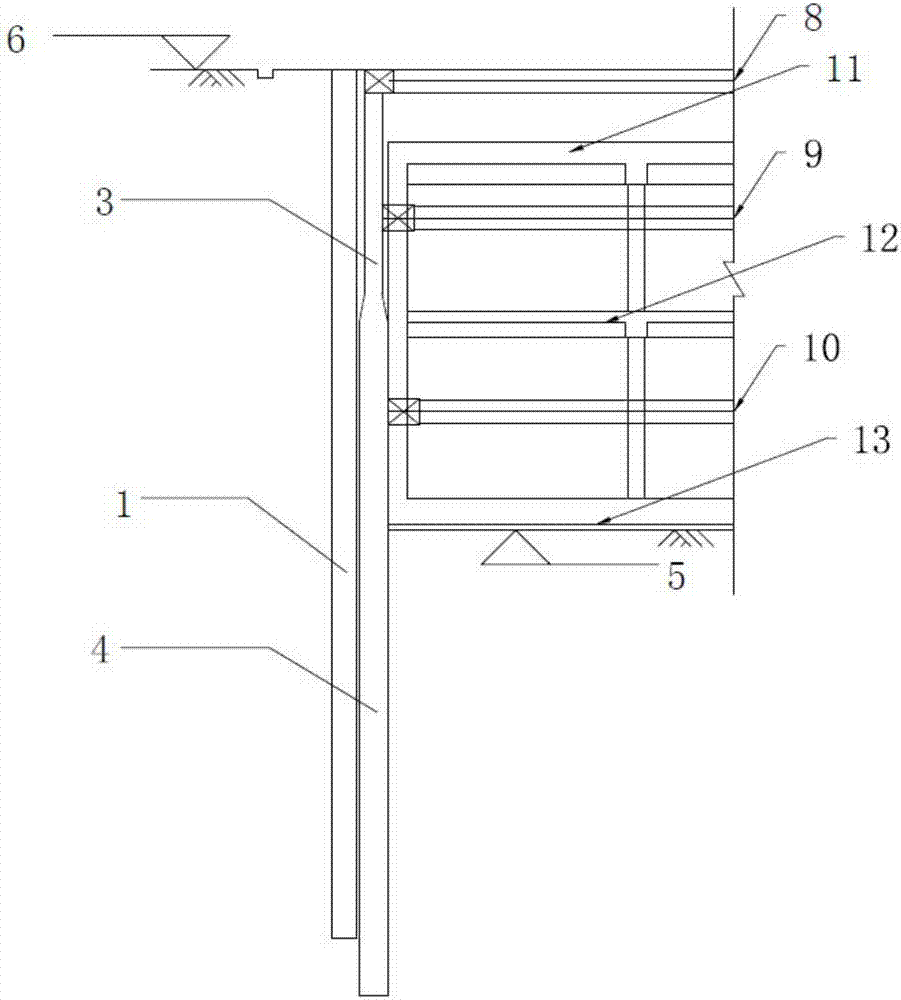

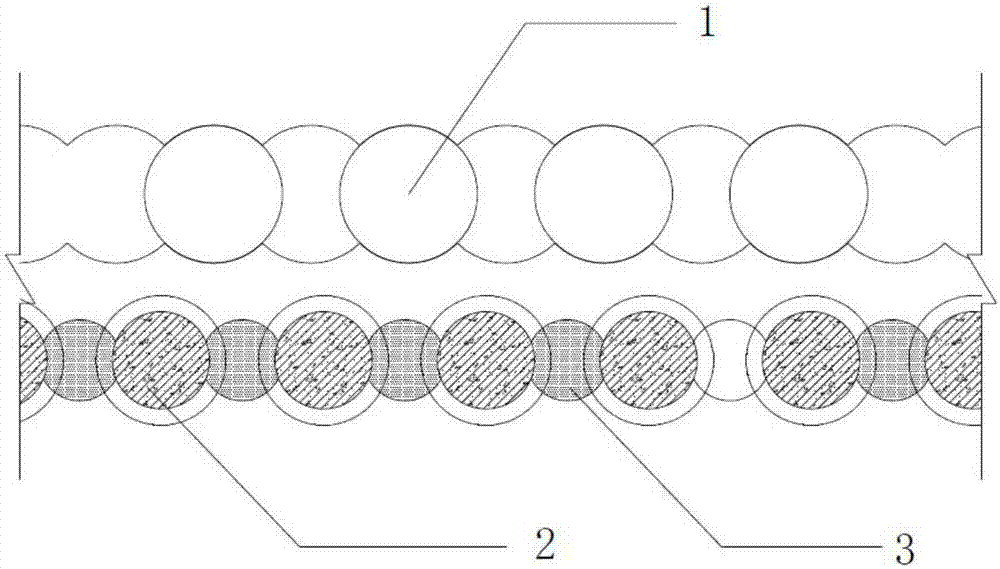

[0019] Such as figure 1 and figure 2 As shown, the variable cross-section bored grouting support pile structure includes a water-stop curtain 1 and several support piles 2, and several support piles 2 are arranged in parallel to form a support wall, and the support wall and water-stop curtain 1 are arranged in parallel. A retaining pile 2 includes a shallow support pile section 3 and a deep support pile section 4 arranged as one, the top of the shallow support pile section 3 is flush with the foundation pit top 6, and the shallow support pile The section diameter of section 3 is smaller than that of deep support pile section 4, and inter-pile soil reinforcement 7 is arranged between every two shallow support pile sections 3 .

[0020] In this embodiment, several support components are arranged on the support pile 2 . The support assembly includes a first support plate 8 , a second support plate 9 and a third support plate 10 from top to bottom, and the first support plate 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com