A method for sealing test and sealing of half-ship floating stern shaft hole or seabed valve box

A submarine valve box and stern shaft technology, which is applied in ship construction, ship design, ship parts, etc., can solve problems such as damage to the steel castings in the stern shaft hole or the outer bottom plate, inconvenient recycling of the sealing plate, and increased ship construction costs. The effect of welding workload, saving labor costs, and reducing the workload of carbon planing and grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

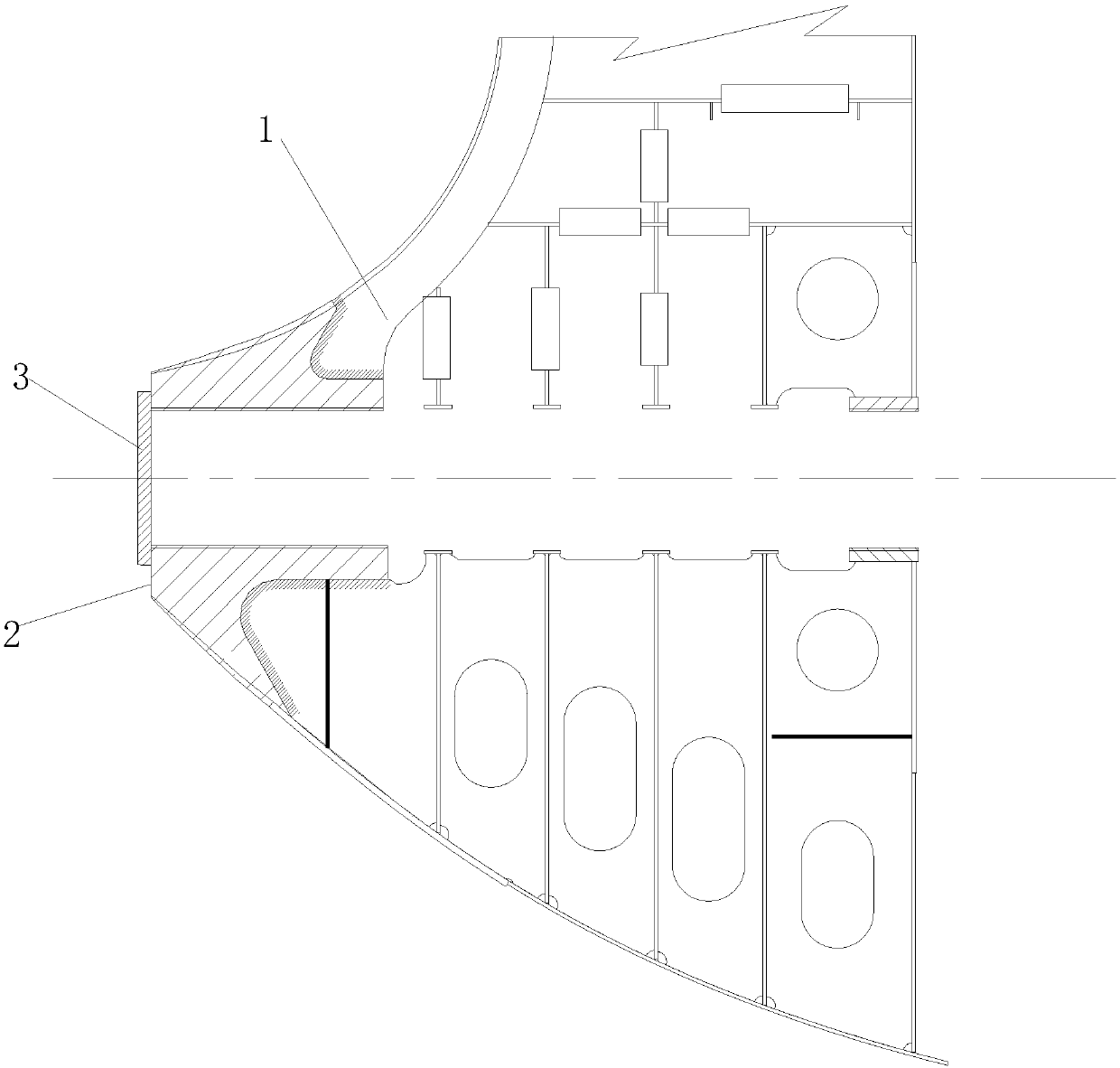

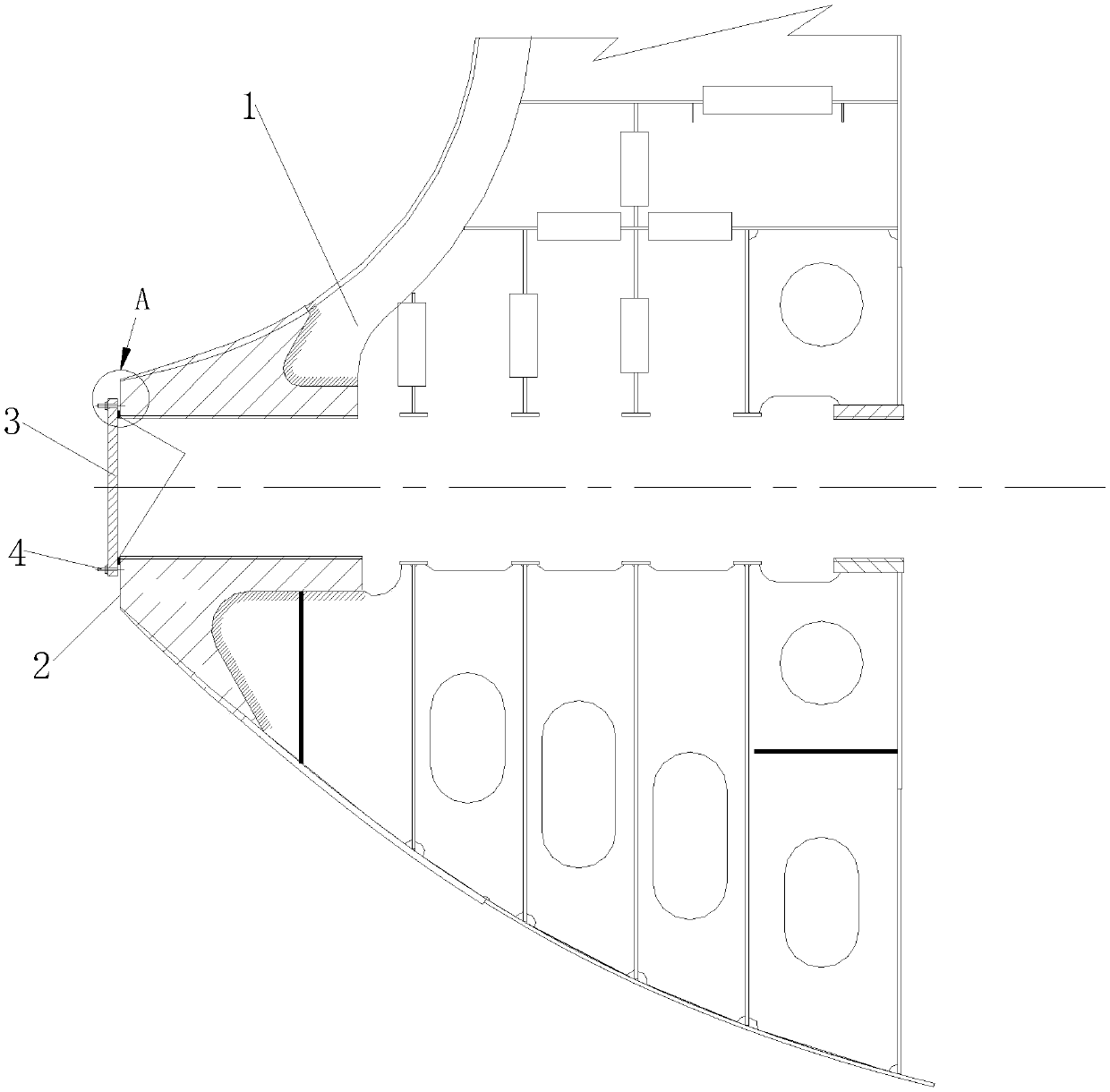

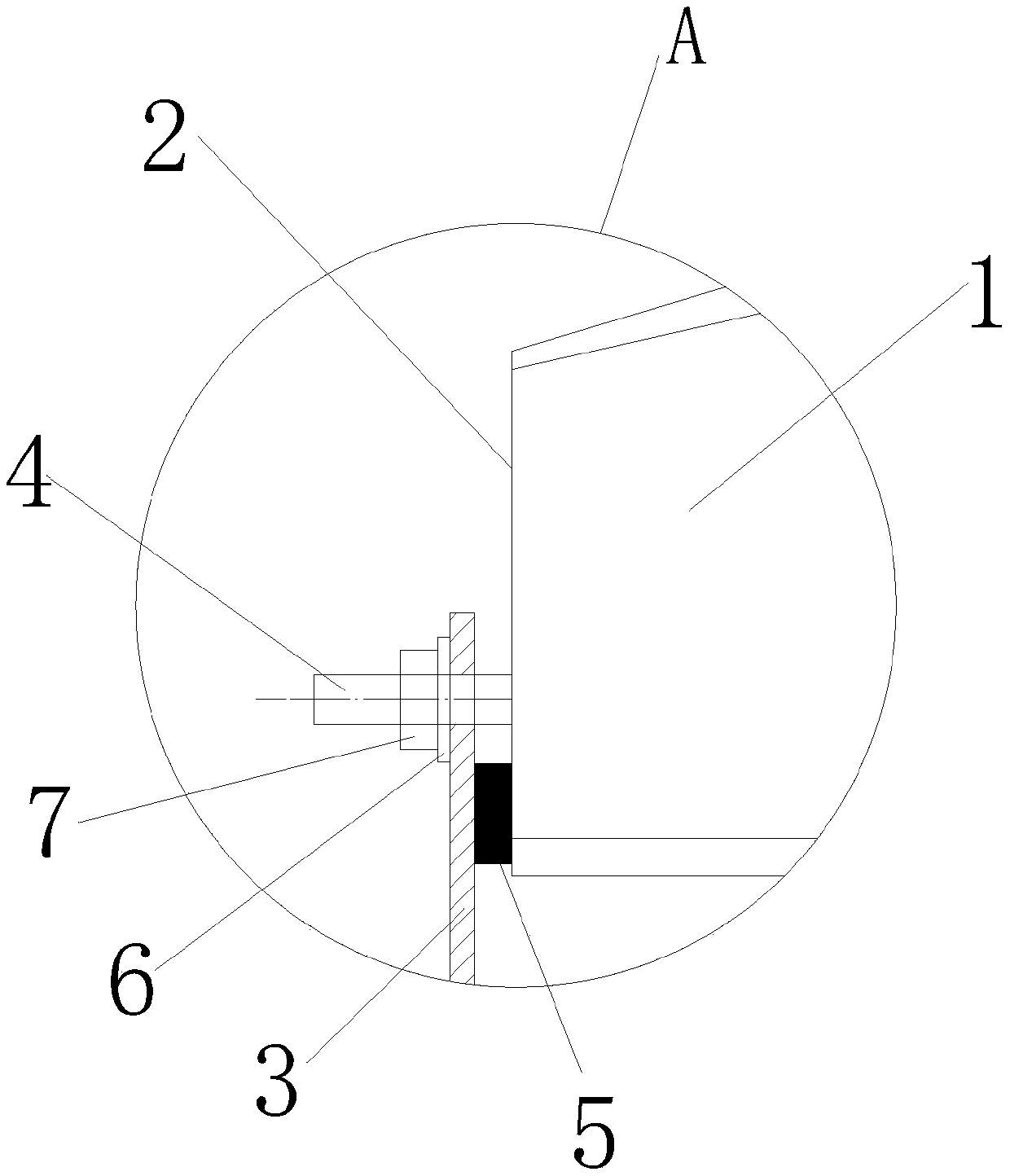

[0025] like figure 2 , 3 As shown, the present embodiment provides a method for sealing test plugging of a semi-vessel hoisting stern shaft hole or a submarine valve box, including the following steps:

[0026] 1) Mark lines for installing bolts on the rear end face 2 of the stern shaft hole or the outer bottom plate of the subsea valve box, and install several screws 4 according to the positions of the marked lines;

[0027] Preferably, the screw 4 is welded and fixed on the rear end face 2 of the tail shaft hole or the outer bottom plate of the subsea valve box by means of stud welding, so as to ensure the reliability of the connection.

[0028] 2) select the blanking material of steel plate to make the blocking plate 3 for blocking the tail shaft hole or the subsea valve box, and open the bolt hole corresponding to the screw 4 on the outer periphery of the blocking plate 3;

[0029] 3) Draw a marking line on the blocking plate 3 according to the size of the aperture of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com