Mold for small-diameter glass reinforced plastic pipeline internal curing production

A fiberglass and internal curing technology, which is applied to home appliances, other home appliances, applications, etc., can solve the problems of easy bending deformation and difficult control of curing temperature, so as to reduce heat loss, reduce thermal bridge effect, and avoid bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] In the present invention, referring to the flow direction of the curing steam, its inflow end is defined as the front end, and its outflow end is defined as the rear end accordingly.

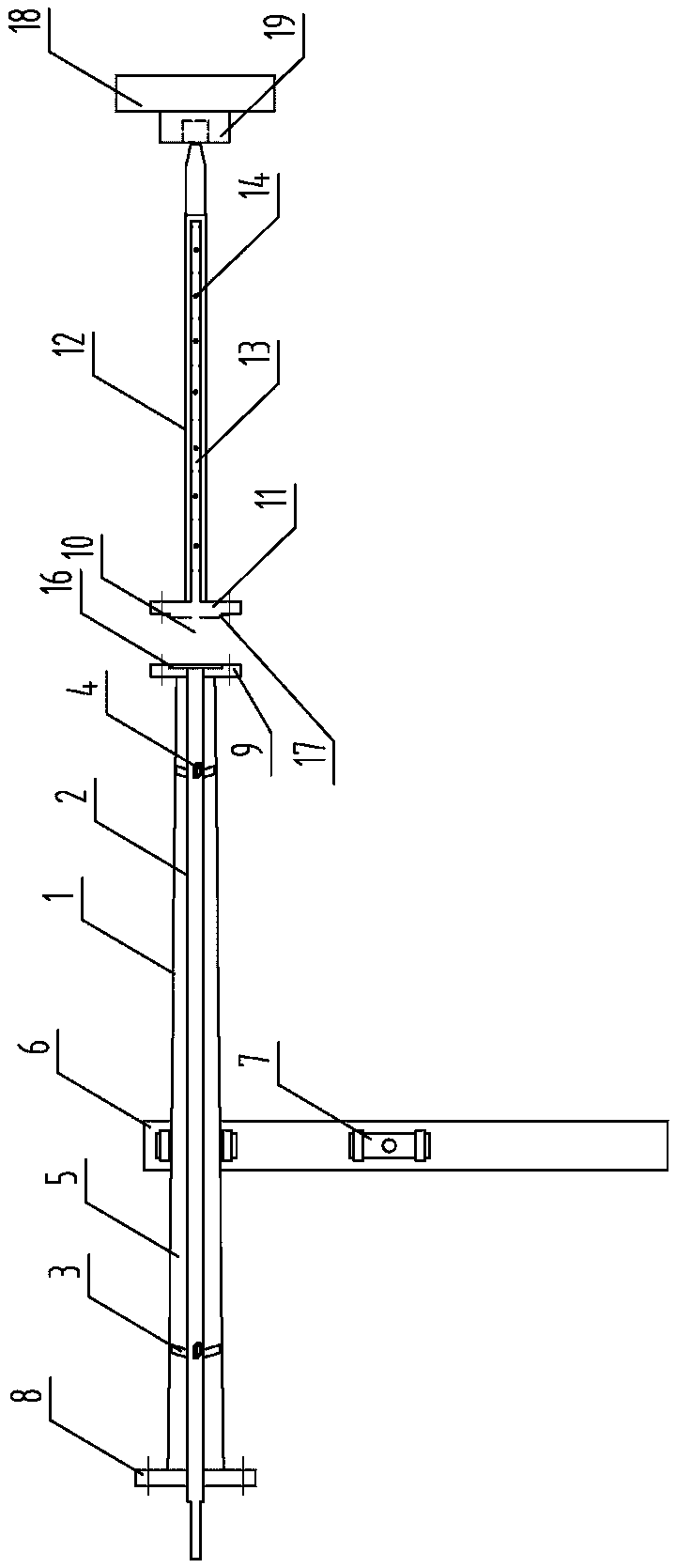

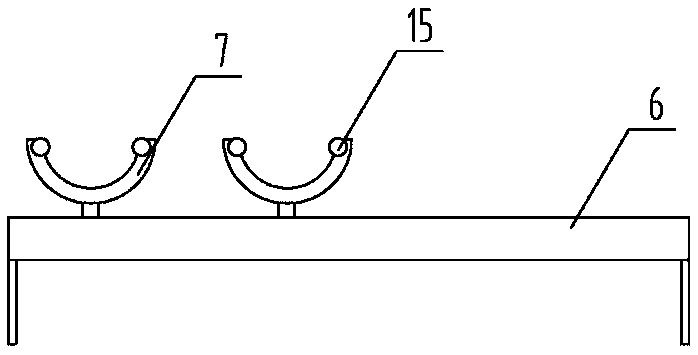

[0033] like figure 1 As shown, in the present invention, an inner cavity is opened in the mold body 12, and a core tube 13 is arranged in the inner cavity, and radial through holes 14 are opened on the tube wall of the core tube 13, and the through holes 14 are evenly arranged. The front end of the mold body 12 fixes the second flange 11, and the inner cavity of the mold body 12 is closed by the second flange 11. The second flange 11 is provided with a protrusion 17 protruding forward, and the protrusion 17 is fitted sealing ring. The front end of the core tube 13 has a socket section 10 protruding from the second flange 11 , and the socket sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com