Preparation technology of pure titanium and titanium alloy ultrafine wire

A preparation process and ultra-fine wire technology, which is applied in the field of pure titanium and titanium alloy ultra-fine wire preparation technology, can solve the problems of difficult control of surface treatment and surface cleaning process, inability to guarantee the surface quality of wire materials, and difficulty in realization, etc. The effect of good quality, high dimensional accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This embodiment provides a preparation process of pure titanium and titanium alloy ultra-fine wire, comprising the following steps:

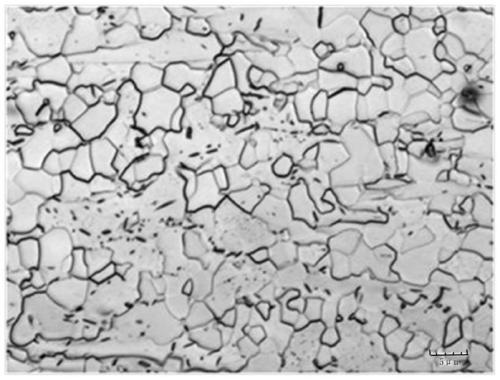

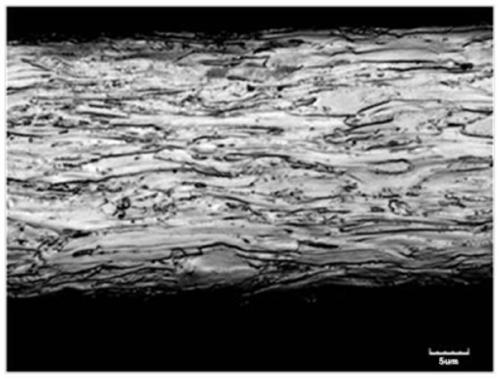

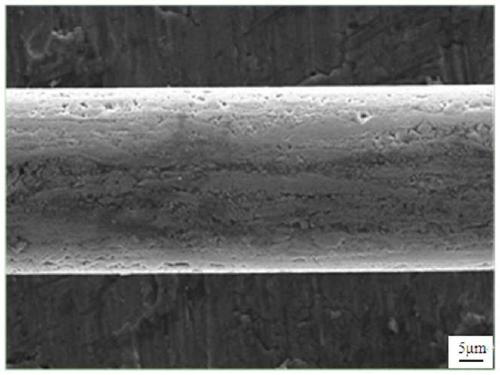

[0026] (1) Room temperature drawing process: the Pure Ti wire billet ( figure 1 The microstructure of the TA1 pure Ti wire base material is given) Each drawing is carried out through a wire drawing die, the drawing speed is controlled at 10m / min, the deformation of a single die is 7%, and graphite milk is used as the drawing process. Lubricant, the graphite milk is industrial drawing graphite milk, its main components include graphite with a content of about 20-25% and a particle size of 1-3 μm; after 20 times of drawing, the cumulative deformation reaches 80%, and the obtained As drawn TA1 ultra-fine wire, the tensile yield strength can reach 900MPa, the tensile strength can reach 1000MPa, and the elongation can reach 2%; figure 2 and image 3 The microstructure and surface morphology of the as-drawn TA1 ultra-fine wire are provide...

Embodiment 2

[0029] This embodiment provides a preparation process of pure titanium and titanium alloy ultra-fine wire, comprising the following steps:

[0030] (1) will The TA1 pure Ti wire billet was drawn through 7 wire drawing dies for the first round, the drawing speed was controlled at 15m / min, the deformation of a single die was 10%, and T-RS-2A type modulation lubricating oil was used as the drawing process. Lubricant; cumulative deformation reaches 52% after 7 die drawing;

[0031] (2) Perform the first intermediate annealing treatment on the wire after the first round of drawing and deformation, and control the vacuum degree to 1×10 - 3 Pa, the annealing temperature is 550±5°C, and the annealing time is 20min;

[0032] (3) Repeat steps (1) and (2) 10 times for the wire after the first intermediate annealing, and finally obtain TA1 ultra-fine wire. in, The tensile yield strength of the drawn TA1 ultra-fine wire can reach 850MPa, the tensile strength can reach 950MPa, and ...

Embodiment 3

[0034] This embodiment provides a preparation process of pure titanium and titanium alloy ultra-fine wire, comprising the following steps:

[0035] (1) will The pure Ti wire blank is drawn in the first round through 3 wire drawing dies, the drawing speed is controlled at 20m / min, the deformation of a single die is 15%, and graphite milk is used as a lubricant in the drawing process, and the graphite milk is Brushed graphite milk for industrial use, its main components include graphite with a content of about 20-25% and a particle size of 1-3μm; the accumulated deformation reaches 38% after being drawn by 3 dies;

[0036] (2) Perform the first intermediate annealing treatment on the wire after the first round of drawing and deformation, and control the vacuum degree to 1×10 - 3 Pa, the annealing temperature is 620±5°C, and the annealing time is 15min;

[0037] (3) Repeat steps (1) and (2) 16 times for the wire after the first intermediate annealing, and finally obtain TA1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com