Circulating frictional electrostatic precipitation device

A technology of electrostatic dust removal and frictional static electricity, applied in the direction of electrostatic separation, electrostatic effect separation, steam flow control, etc., can solve the problems of low investment and low electrification intensity, achieve low energy consumption and improve friction electrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

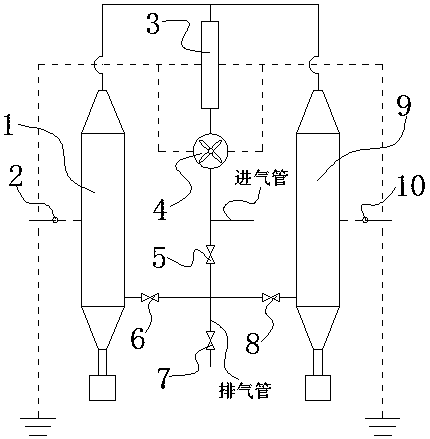

[0014] The following is attached figure 1 , attached figure 2 , attached image 3 , with Figure 4 , attached Figure 5 , the present invention will be described in further detail through the embodiments.

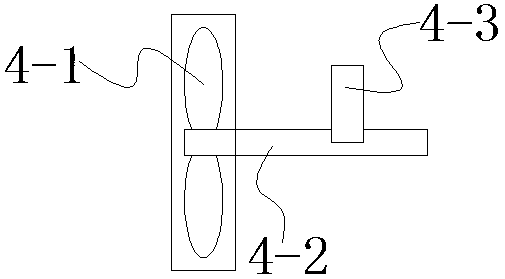

[0015] A circulating friction electrostatic precipitator is composed of a first electrostatic precipitator 1 , a second electrostatic precipitator 9 , a friction generator 3 , a centrifugal fan 4 , a first single-pole double-throw switch 2 and a second single-pole double-throw switch 10 . The first electrostatic precipitator chamber 1 is surrounded by a cylinder and a cone-shaped head arranged at the upper and lower ends of the cylinder. The shaped head communicates with a dust collection chamber through a section of steel pipe; the structure of the second electrostatic precipitator 9 is the same as that of the first electrostatic precipitator 1; the friction generator 3 is a section of borosilicate glass tube 3 whose inner surface is corrugated -1, the outer surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com