Pressure self-balancing type reaction kettle

A self-balancing, reactor technology, applied in chemical/physical/physicochemical fixed reactors, pressure vessels/vacuum vessels, pressure vessels used in chemical processes, etc. Increase and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

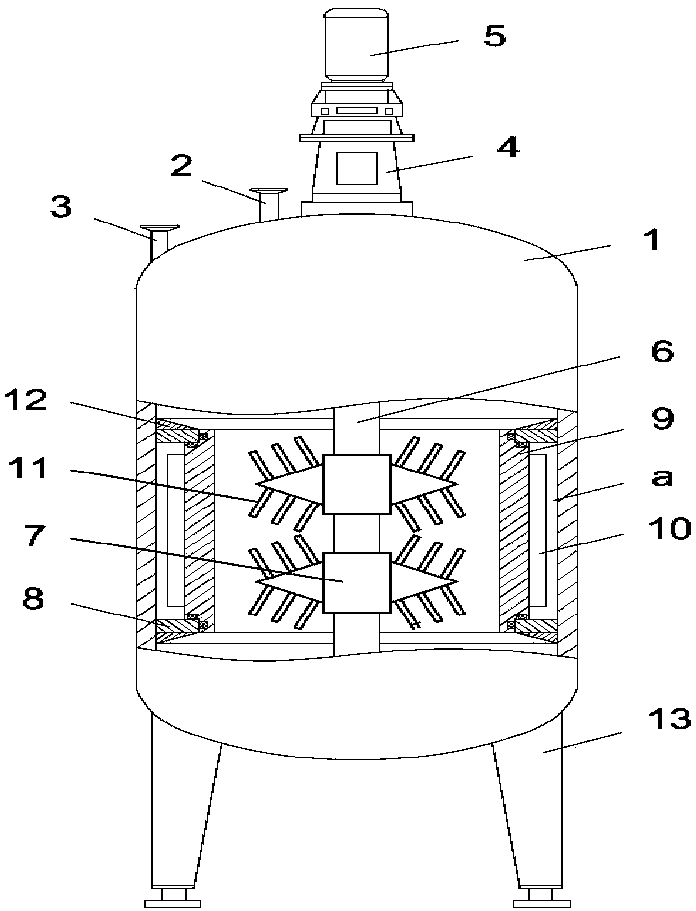

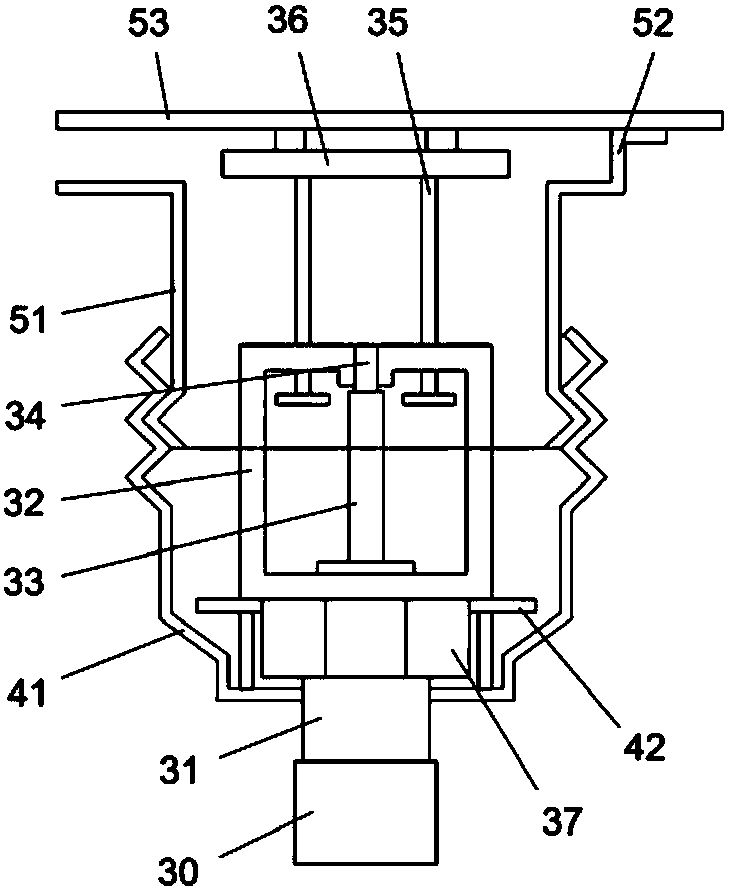

[0017] like Figure 1-2 As shown, a pressure self-balancing reaction kettle includes a kettle body 1, a sampling pipe 2, a pressure relief valve 3 and a motor bracket 4 are fixed on the top of the kettle body 1, and a stirring motor 5 is fixed on the motor bracket 4, and the stirring motor The rotating shaft of 5 is fixedly connected by the motor coupling and the stirring mechanism; the pressure relief valve 3 includes a movable body 51 and a fixed body 41, the outer wall of the movable body 51 is provided with an engaging part 1, and the outer wall of the fixed body 41 is provided with an engaging part 1; Part two, the fixed body 41 is plugged into the inside of the movable body 51, the engaging part 1 and the engaging part 2 are clam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com