A vehicle-mounted non-contact catenary geometric parameter dynamic detection system and method

A geometric parameter, dynamic detection technology, applied in the field of detection, can solve the problems of complex structure, low precision, difficult installation, etc., to achieve the effect of high detection precision, wide versatility and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

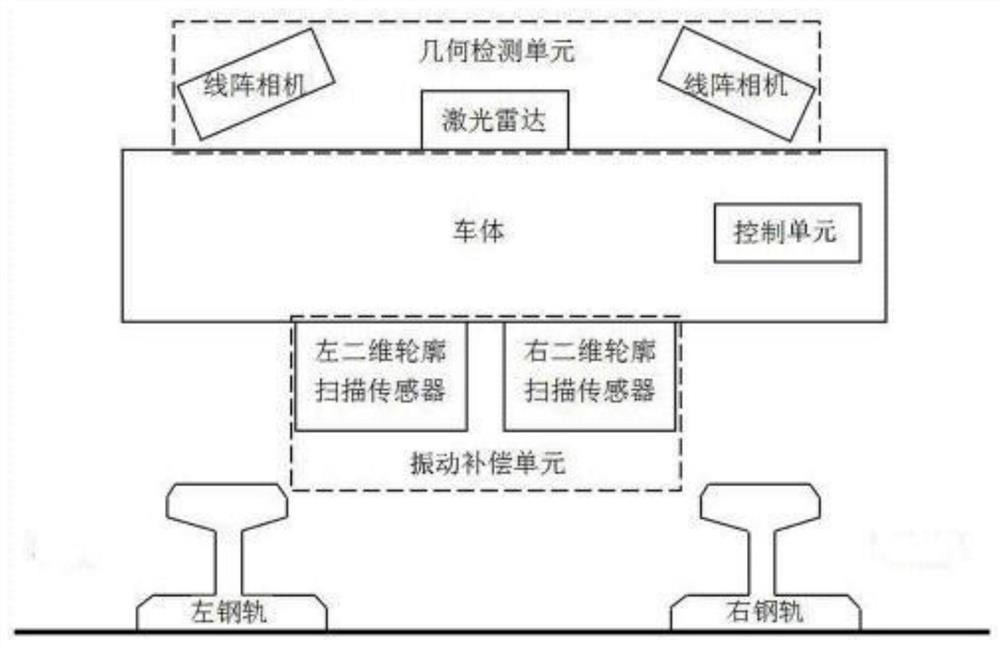

[0035] This embodiment provides a vehicle-mounted non-contact catenary dynamic detection system for geometric parameters. Such as figure 1 As shown, it includes a geometric detection unit located on the top of the vehicle body for detecting the catenary, a control unit installed inside the vehicle body, and a vibration compensation unit located at the bottom of the vehicle body for detecting the vibration of the vehicle body.

[0036] The vibration compensation unit is located at the bottom of the vehicle and is composed of two two-dimensional contour scanning sensors; and the geometric detection unit and the vibration compensation unit are installed in the same cross section of the vehicle body perpendicular to the rail.

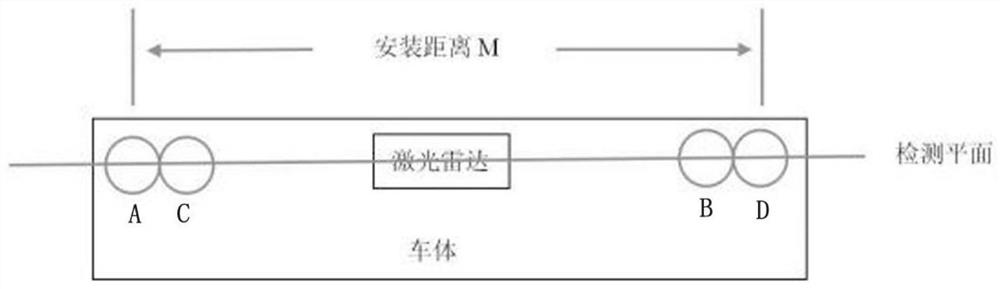

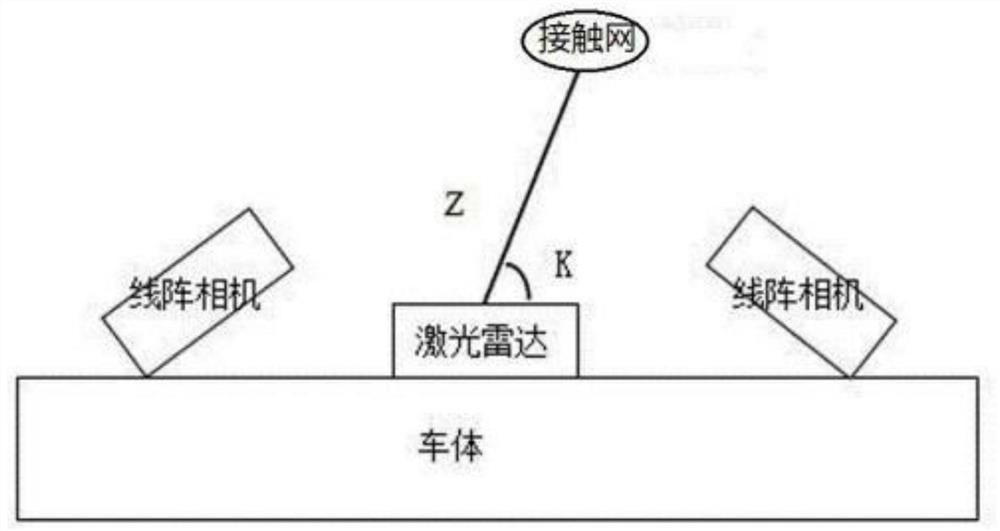

[0037] Such as figure 2 , image 3 As shown, the geometric detection unit is located in the center of the car body, including a lidar, four line array cameras, light sources and mounting brackets. The lidar and line array cameras are installed on the top...

Embodiment 2

[0042] This embodiment provides a detection method using Embodiment 1.

[0043] Include the following steps:

[0044] S1. Use the lidar and the line array camera to detect the spatial position of the catenary on the roof.

[0045] Before the actual detection, the line scan camera is calibrated, the process is as follows.

[0046] S11. Using the regression technique, perform camera calibration on the line scan camera used for measuring the catenary in advance.

[0047] S111 acquires the training data, and obtains the corresponding relationship between the world coordinates and the pixel coordinates of the line array camera;

[0048]During the calibration process, objects with known spatial position information are usually used as scenes for shooting, and such objects are called calibration objects. In this embodiment, a black strip is used as a calibration object, which is photographed from several perspectives. Considering that the target surface of the line scan camera is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com