Supporting shaft for integral type axle and manufacturing method thereof

A manufacturing method and a technology for supporting shafts, which are applied in the field of vehicles, can solve problems such as high input costs, high manufacturing costs, and difficulty in adapting to the development trend of manufacturing flexibility, and achieve the effects of cost reduction, large section modulus, and large overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0047] The invention relates to a support shaft for a monolithic vehicle axle, where the monolithic vehicle axle can be either a supporting axle or a steering axle. For the supporting axle, the supporting shaft may not have a corresponding structure assembled with the steering knuckle, and for the steering axle, the supporting shaft may have a corresponding structure assembled with the steering knuckle (as according to the supporting shaft in the preferred embodiment of the present invention) shaft ends).

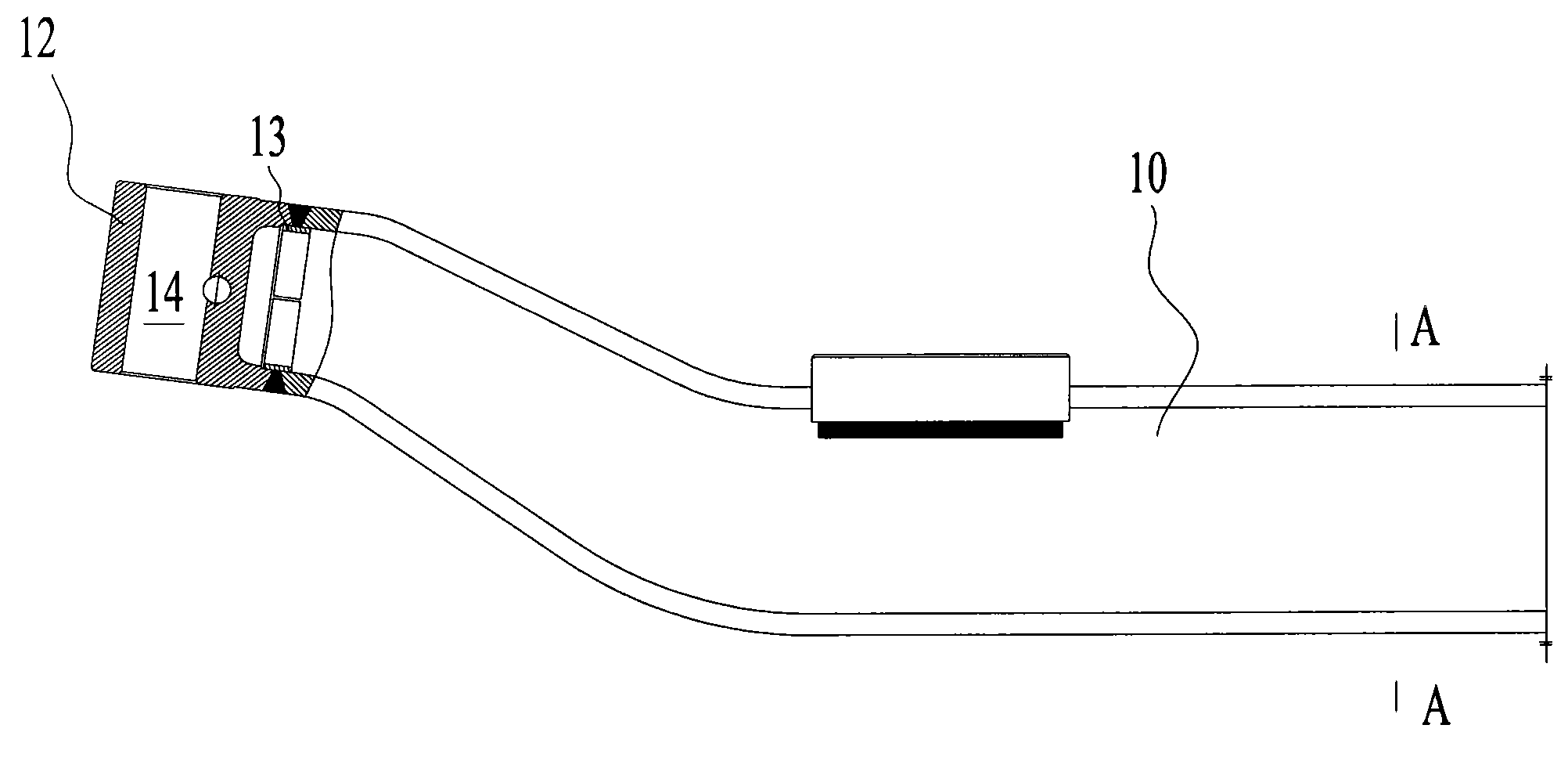

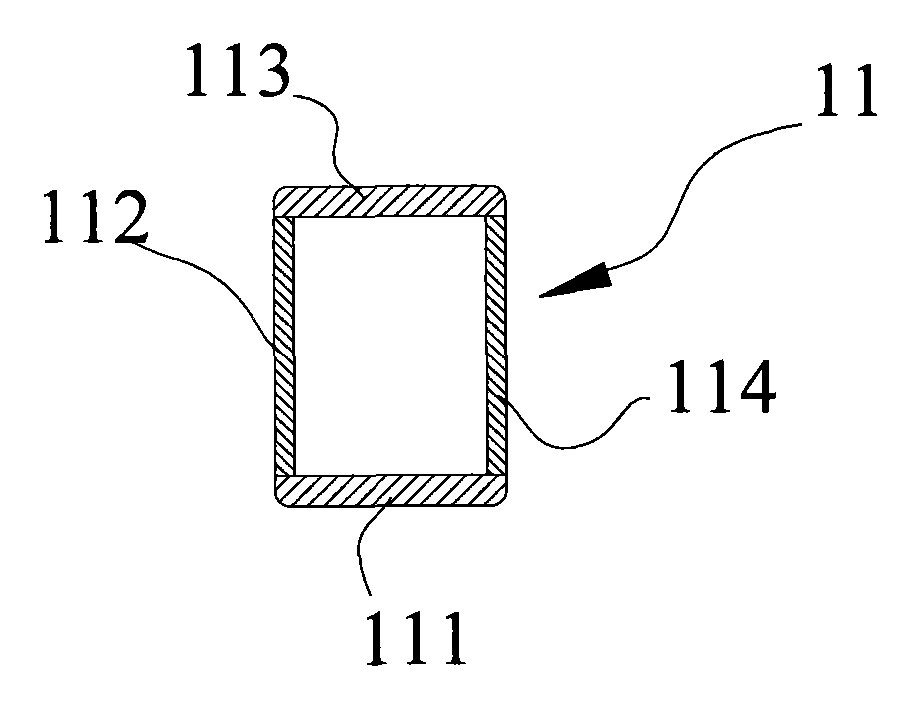

[0048] Such as figure 1 As shown, the support shaft for integral axle provided by the present invention includes a support shaft body 10, wherein, the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com