A tool for detecting the position and size of holes on the surface of parts

A technology of size detection and surface hole, applied in the direction of measuring device, mechanical measuring device, using mechanical device, etc., can solve the problem that the position of the surface hole of the part cannot be positioned and measured as a whole, so as to meet the needs of design and production, the results are accurate, and the scope of application is improved. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

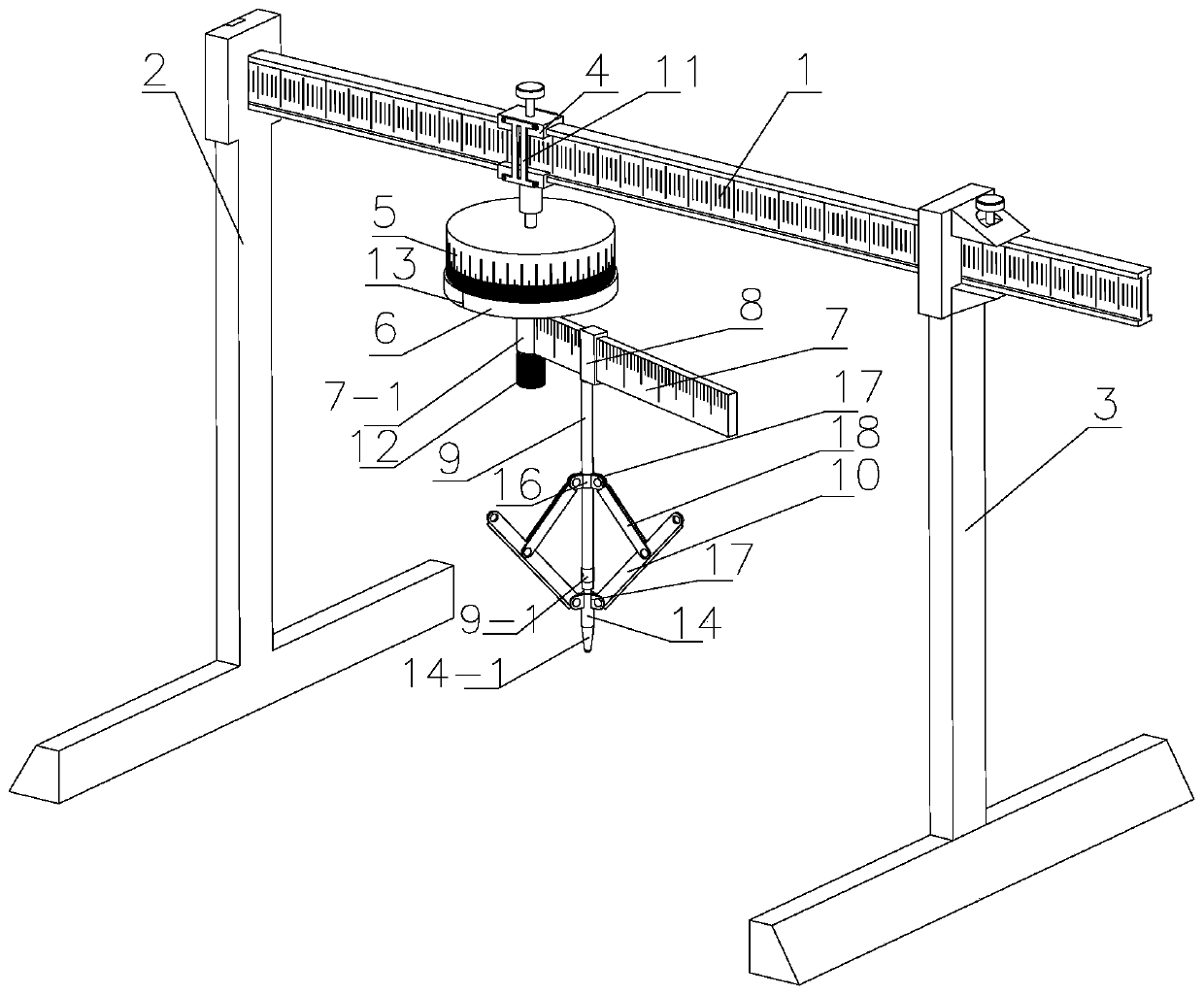

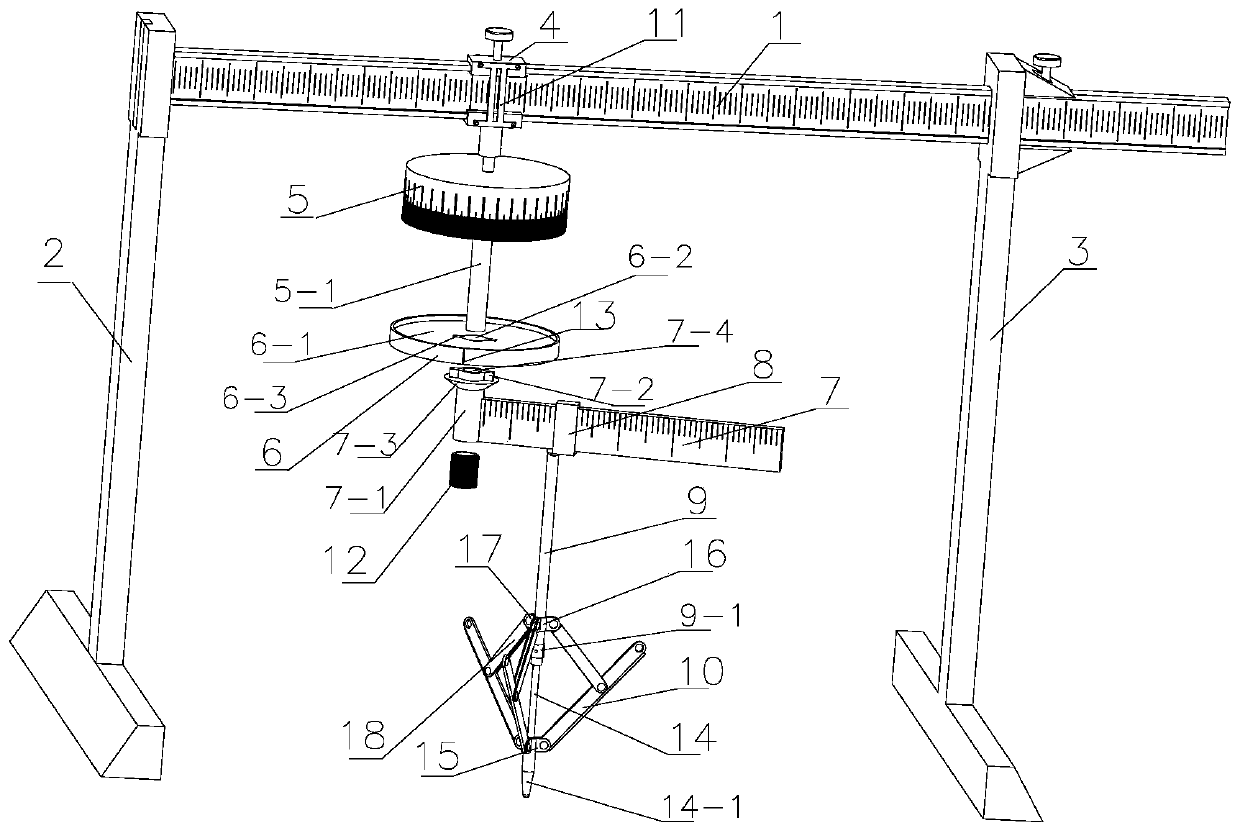

[0020] Such as Figure 1~2 As shown, a tool for detecting the position and size of holes on the surface of a part includes a diameter scale 1, a measuring assembly and a positioning assembly. One end of the diameter scale 1 is fixed with a fixed base 2, and the other end of the sliding sleeve is provided with a movable base 3. A main vernier 4 is slidably arranged on the diameter scale 1 , and the measuring assembly is fixed on the bottom of the main vernier 4 ; a counter 11 is fixed on the main vernier 4 .

[0021] The measuring assembly includes an angle plate 5, an angle measuring plate 6 and a secondary measuring ruler 7, the angle plate 5 is fixed on the main vernier 4, and the angle measuring plate 6 is rotatably arranged on the angle plate 5, so The auxiliary measuring ruler 7 is fixed on the angle measuring disc 6, the auxiliary measuring ruler 7 is perpendicular to the axis of the angle disc 5, and the auxiliary measuring ruler 7 is slidably provided with an auxiliary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com