A method for positioning the side orientation of an object

A positioning method and side orientation technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of large volume, high cost, and high requirements for working space of positioning tooling, and achieve simple structure, low cost, and mechanical equipment and the effect of less manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

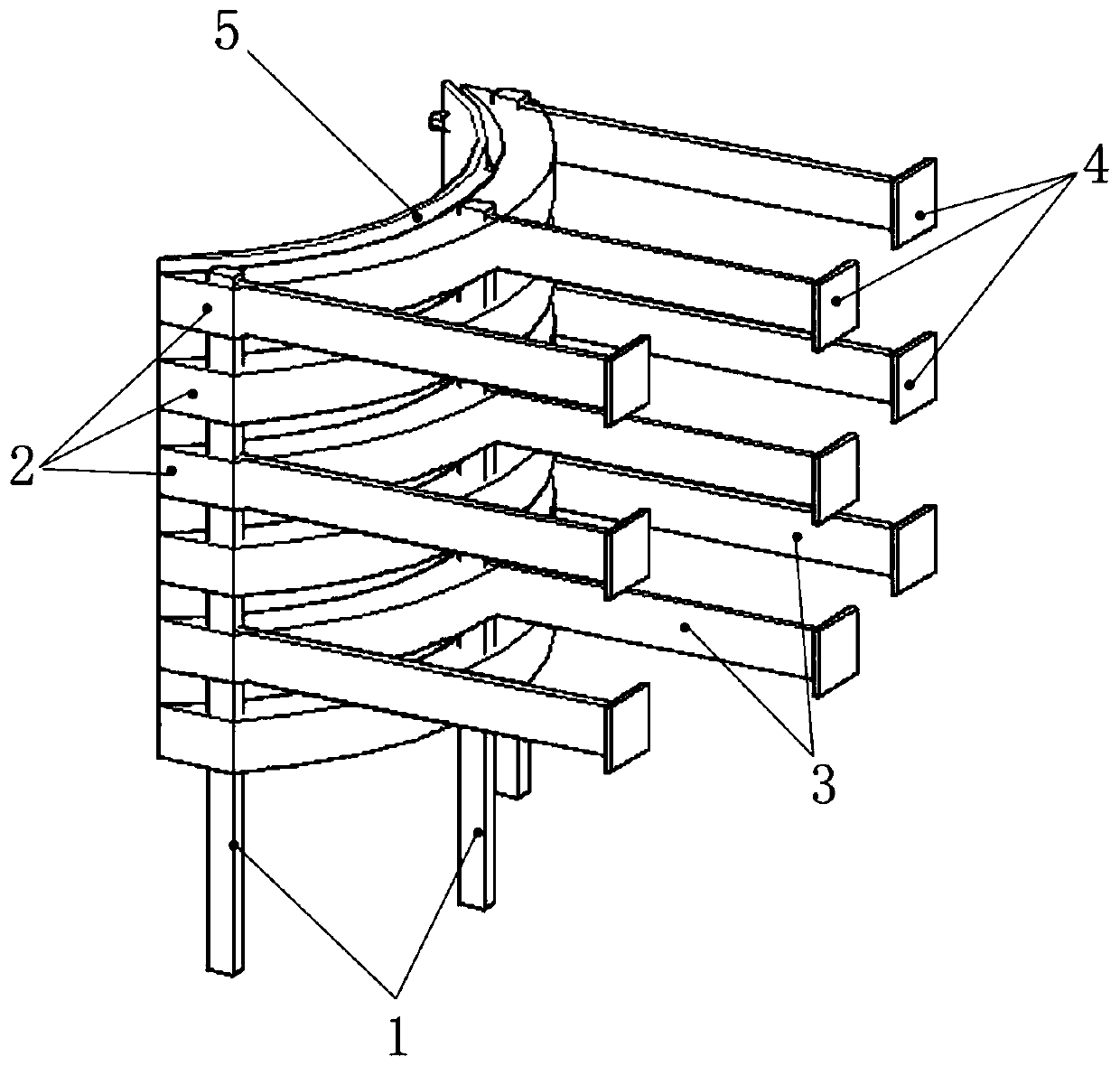

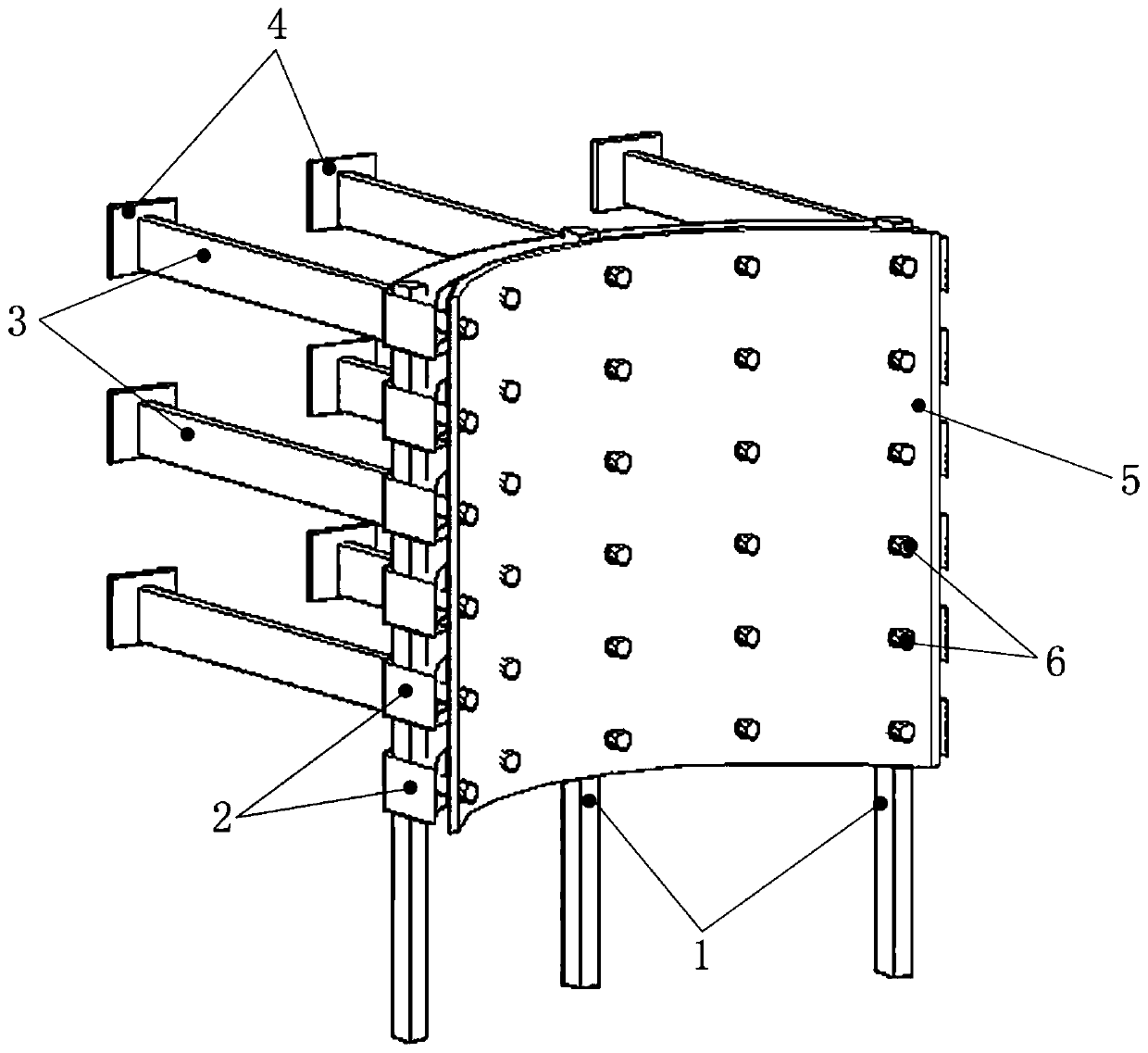

[0024] as attached figure 1 and figure 2 As shown, a side orientation positioning method of an object comprises the following steps:

[0025] (1) Arranging welded steel plates 4 at the outer ends of multiple cross beams 3, and at the same time, fixing the outer sides of the welded steel plates 4 on the object to be fixed;

[0026] (2) Fixing the inner ends of a plurality of beams 3 to the outer surface of a frame whose cross section is an arc-shaped structure, and simultaneously, fixing a plurality of columns 1 in the frame as a vertical support of the frame;

[0027] (3) The liner plate 5 is fixed on the inner surface of the frame body by the fixing bolt 6, and fits with the frame body whose cross section is an arc-shaped structure;

[0028] (4) The object to be positioned is located inside the liner 5 and close to the inner surface of the liner 5 to complete the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com