High-strength geotechnical cloth and manufacturing method thereof

A manufacturing method and technology of geotextiles, applied in geotextiles, textiles, papermaking, heating/cooling fabrics, etc., can solve the problems of poor deformation resistance, difficulty in strengthening, and low strength, so as to improve the joint strength and increase the size The effect of stability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to further understand the contents of the present invention, the present invention will be described in detail in conjunction with examples. It should be understood that the examples are only for explaining the present invention and not for limiting it.

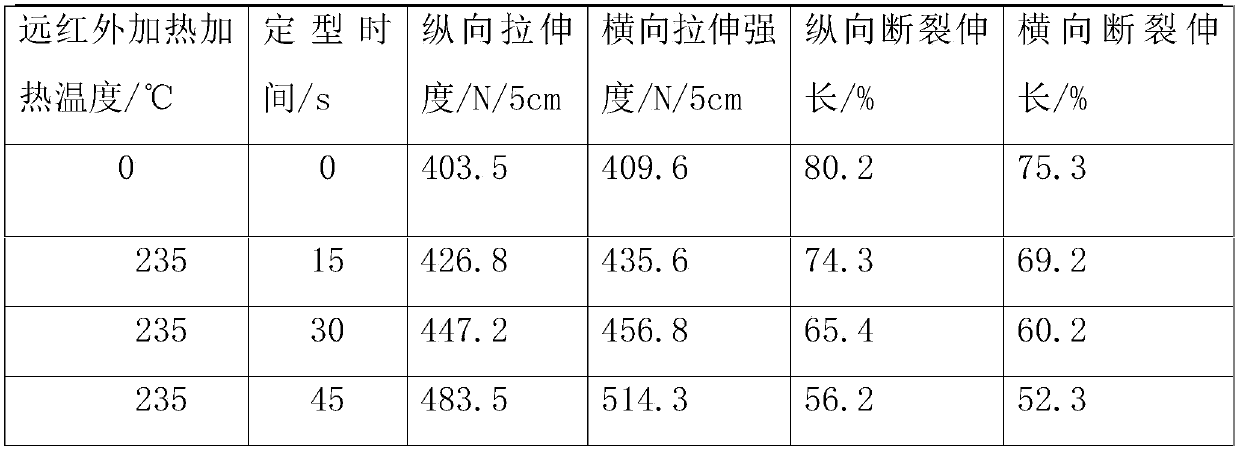

[0014] This embodiment provides a high-strength geotextile and its manufacturing method, including the following steps: opening of non-woven production equipment; carding; messing; laying; needle punching;

[0015] In this embodiment, the non-woven production equipment is any one of a non-woven bag making machine, a non-woven slitting machine or a needle punching machine.

[0016] In this embodiment, the carding machine combs the small cotton bundles prepared by opening and mixing into a thin web composed of single fibers.

[0017] In this embodiment, the disorder is that the short fibers are intertwined with each other.

[0018] In this embodiment, the web laying method is standardized entanglement.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com