Phosphogypsum putty powder prepared from phosphogypsum

A technology of phosphogypsum and putty powder is applied in the field of comprehensive utilization of renewable resources, which can solve the problems of affecting appearance and low strength, and achieve the effects of good decoration effect, fast coagulation and hardening, and good breathing function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

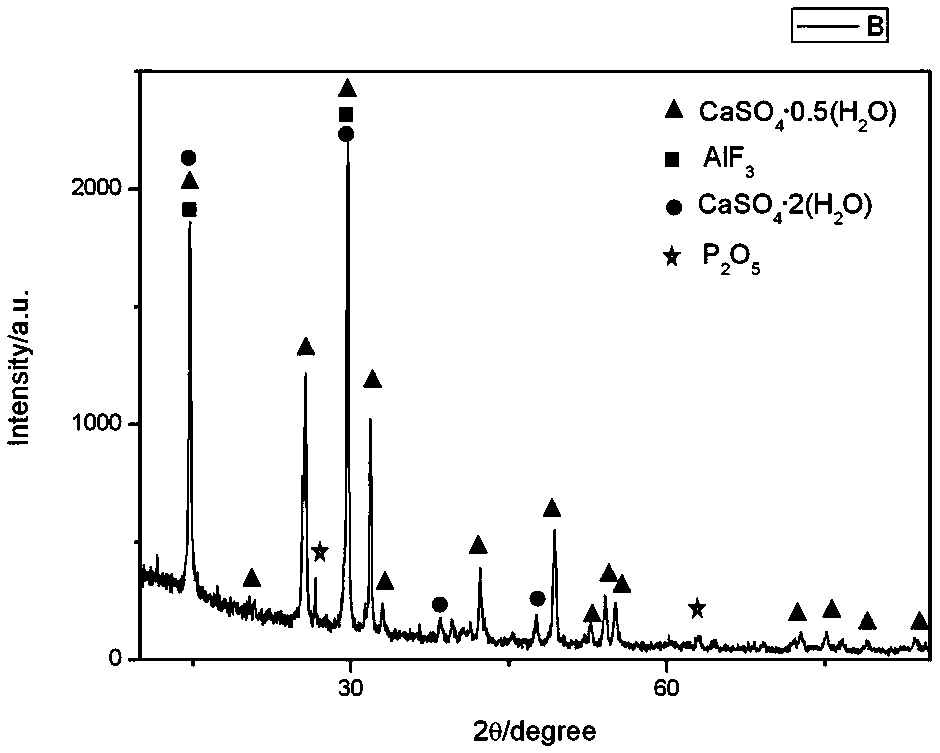

Image

Examples

Embodiment 1

[0040] The preparation operation steps of decolorized phosphogypsum are as follows:

[0041] (1) Put the phosphogypsum in a ball mill tank for ball milling, the ball milling speed is 300 r / min, mill for 1 hour, and get 300 mesh phosphogypsum powder;

[0042] (2) Put the phosphogypsum powder in a tube furnace, calcined at 400°C for 30 minutes, and naturally cooled to room temperature to obtain calcined phosphogypsum;

[0043] (3) Put calcined phosphogypsum and sulfuric acid solution with a mass fraction of 20% in a beaker according to the solid-to-liquid ratio of 1:4, stir at 80°C for 60 minutes, and then filter with suction (tightly connect the Buchner funnel to the suction filter bottle Connect, connect the air pump, put the filter paper into the Buchner funnel, moisten the filter paper with distilled water, slowly pour the solution stirred at constant temperature into the Buchner funnel, turn on the switch of the air pump, and start the suction filtration), washing (filter ...

Embodiment 2

[0050] The preparation operation steps of decolorized phosphogypsum are as follows:

[0051] (1) Put the phosphogypsum in a ball mill tank for ball milling, the ball milling speed is 300 r / min, mill for 1 hour, and get 300 mesh phosphogypsum powder;

[0052] (2) Put the phosphogypsum powder in a tube furnace, calcined at 400°C for 30 minutes, and naturally cooled to room temperature to obtain calcined phosphogypsum;

[0053] (3) Put calcined phosphogypsum and sulfuric acid solution with a mass fraction of 20% in a beaker according to the solid-to-liquid ratio of 1:4, stir at 80°C for 60 minutes, and then filter with suction (tightly connect the Buchner funnel to the suction filter bottle Connect, connect the air pump, put the filter paper into the Buchner funnel, moisten the filter paper with distilled water, slowly pour the solution stirred at constant temperature into the Buchner funnel, turn on the switch of the air pump, and start the suction filtration), washing (filter ...

Embodiment 3

[0062] The preparation operation steps of decolorized phosphogypsum are as follows:

[0063] (1) Put the phosphogypsum in a ball mill tank for ball milling, the ball milling speed is 300 r / min, mill for 1 hour, and get 300 mesh phosphogypsum powder;

[0064] (2) Put the phosphogypsum powder in a tube furnace, calcined at 400°C for 30 minutes, and naturally cooled to room temperature to obtain calcined phosphogypsum;

[0065] (3) Put calcined phosphogypsum and sulfuric acid solution with a mass fraction of 20% in a beaker according to the solid-to-liquid ratio of 1:4, stir at 80°C for 60 minutes, and then filter with suction (tightly connect the Buchner funnel to the suction filter bottle Connect, connect the air pump, put the filter paper into the Buchner funnel, moisten the filter paper with distilled water, slowly pour the solution stirred at constant temperature into the Buchner funnel, turn on the switch of the air pump, and start the suction filtration), washing (filter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com