A kind of track crane installation method

An installation method and technology of rail hoisting, applied in the direction of rail system, transportation and packaging, load hoisting components, etc., can solve the problems of inability to fully install in place, large weight and size, etc., to ensure installation size, reduce requirements, and reduce heights effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

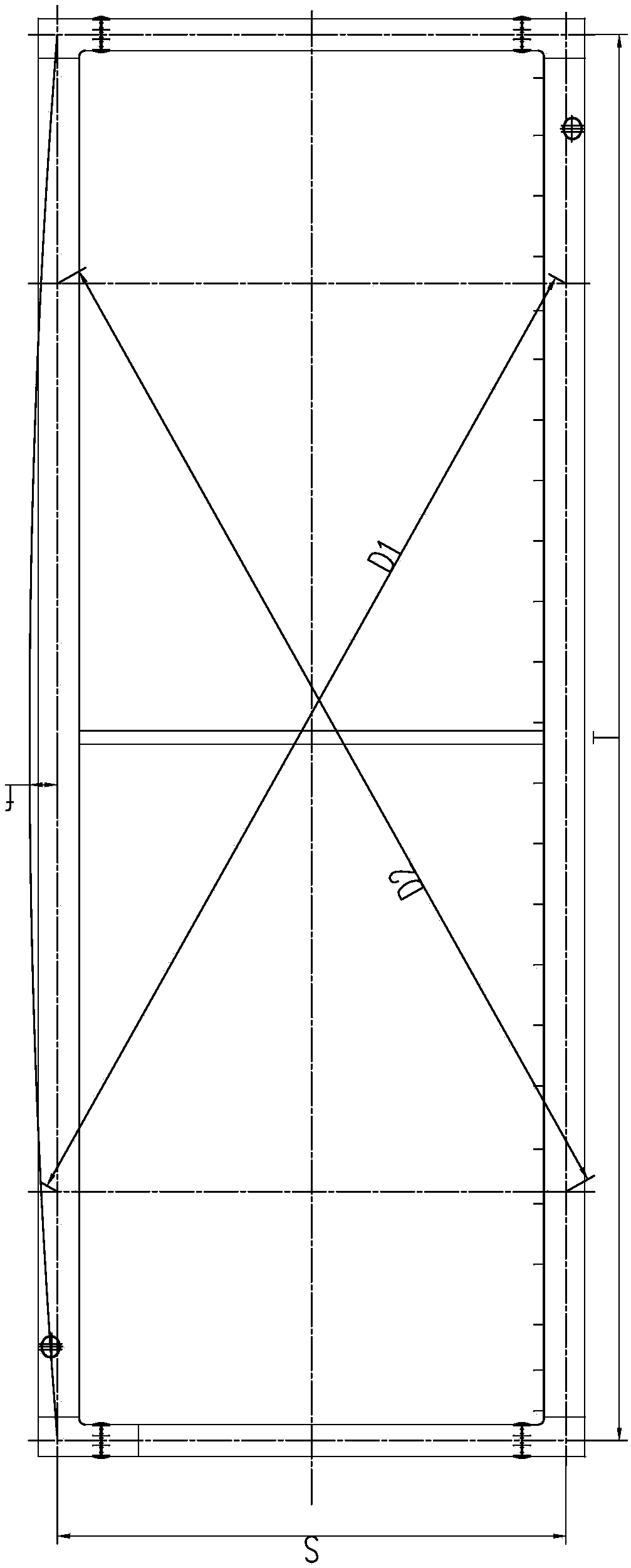

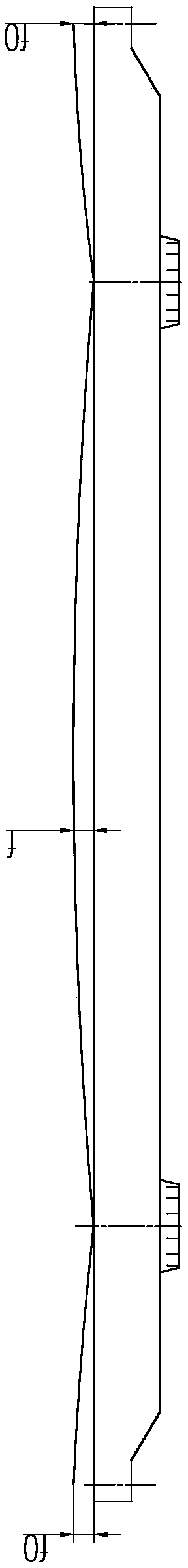

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the embodiments in the drawings:

[0034] The present invention mainly includes the following steps:

[0035] The first step is to arrange the traveling mechanism of the cart:

[0036] (1.1) Trolley track laying: Before installing the trolley running mechanism, lay the qualified trolley track and inspect the trolley track to check whether the trolley track installation meets the standards;

[0037] (1.2) Hoisting of the cart running mechanism: After the cart track is qualified, the cart running mechanism is hoisted to the cart track and the wheel tooth side rim of the cart running mechanism is close to the track;

[0038] (1.3) Installation of accessory parts of the cart running mechanism: After the cart running mechanism is hoisted, use the pin to connect the cart connecting bracket to the upper part of the cart running mechanism and adjust the position to ensure that the cart connecting bracket and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com