Pod propeller combination tooling

A technology of propellers and pods is applied in the field of combined tooling of podded propellers, which can solve the problems of increasing the number of tooling and production costs, increasing labor intensity, and being prone to danger, and achieving convenient combination, improving manufacturing efficiency, and reducing production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

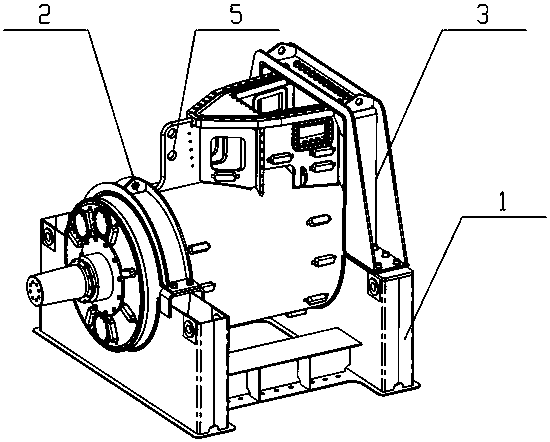

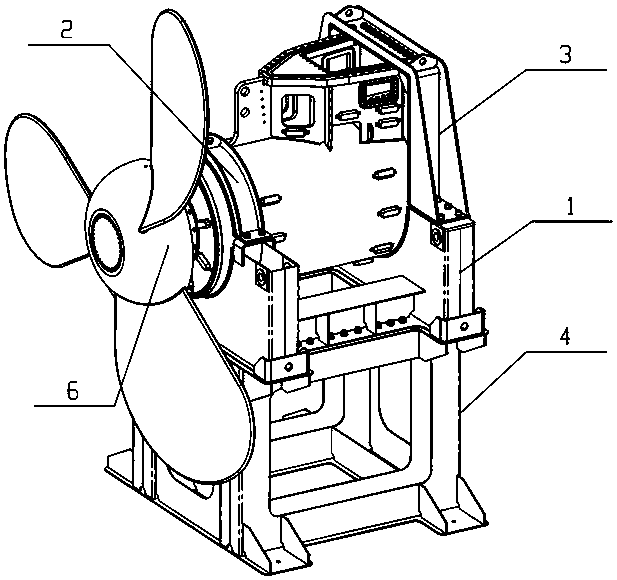

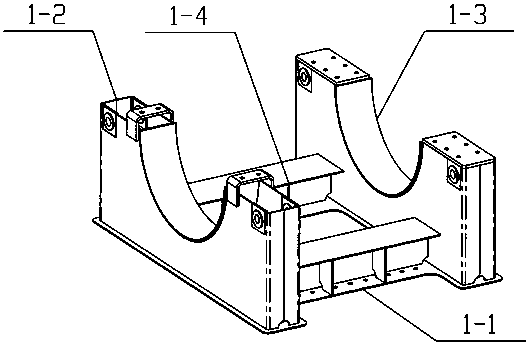

[0022] A kind of pod propeller assembly tool provided in this embodiment, such as Figure 1-Figure 6 As shown, it includes a base 1, a paddle end lock 2 and a paddle end lock 3. The base 1 includes a wall bracket near the paddle end 1-2, a wall bracket 1-3 at the far paddle end, and a base plate 1-1. The end wall frame 1-2 and the far paddle end wall frame 1-3 are symmetrically arranged on both sides of the base bottom plate 1-1, and the two ends of the arc bending plate 2-1 locked near the paddle end are connected with the near paddle end wall frame 1-1. 2 Connected by fasteners, the two ends of the U-shaped bent steel plate 3-1 locked at the far paddle end 3 are fixedly connected to the wall frame 1-3 at the far paddle end, and the top of the U-shaped bent steel plate 3-1 is connected to the pod The flange face of the body 5 top.

[0023] Also includes a support platform 4, the support platform 4 includes a platform base plate 4-1, two support frames 4-2 are symmetrically i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com