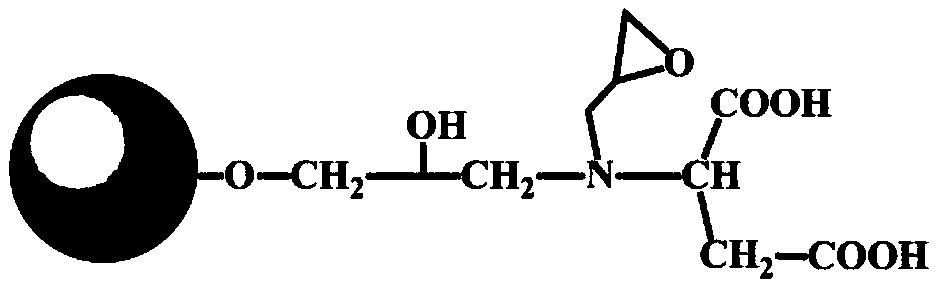

Active carrier and preparation method for directional immobilization of protein A and preparation method of protein A immunoadsorption material

An immunoadsorption material and active carrier technology, applied in the field of protein immobilization, can solve the problems of high price, high synthesis cost of succinimide-based carrier, loss of activity, etc., to reduce production cost and protein A immunoadsorption therapy Cost, effect of improving adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

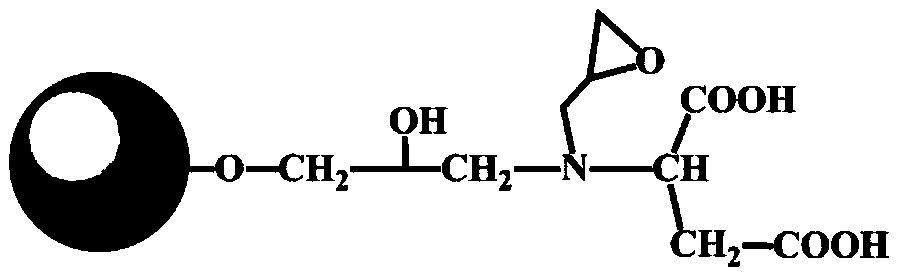

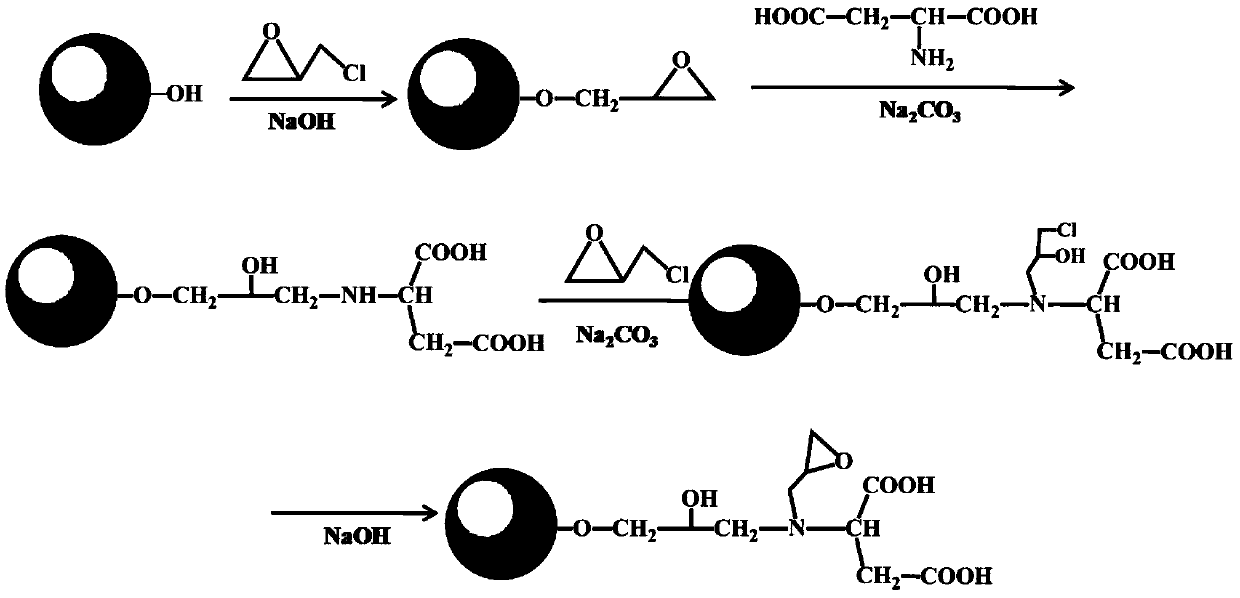

[0034] 1. Preparation of active carrier

[0035](1) Epichlorohydrin activation: take 100mL of agarose gel microspheres (Sepharose 6FF), rinse with distilled water, drain, add to a 1000mL round bottom flask, add 150mL of 3mol / L sodium hydroxide aqueous solution , 0.3 g of sodium borohydride, 100 mL of epichlorohydrin, placed in a constant temperature shaker, reacted at 40 ° C for 2 hours, rinsed with a large amount of distilled water until neutral, and ended the reaction. The amount of epoxy groups on the carrier was detected by the sodium thiosulfate method, and it was measured that there were 55 μmol of epoxy groups per gram of the carrier.

[0036] (2) Bonded aspartic acid: Take 100 mL of the agarose gel obtained by the reaction in step (1), wash it with a large amount of distilled water, drain it and add it to a 1000 mL round bottom flask, add 500 mL of 1.5 mol / L The aspartic acid solution (adjusted to pH 12 with sodium carbonate) was placed in a constant temperature shake...

Embodiment 2

[0061] 1. Preparation of active carrier

[0062] (1) Epichlorohydrin activation: take 100mL cellulose microspheres (MT500, 80-100μm), rinse with distilled water, drain, add to a 1000mL round bottom flask, add 150mL 2mol / L sodium hydroxide Aqueous solution, 0.3 g of sodium borohydride, 100 mL of epichlorohydrin, placed in a constant temperature shaker, reacted at 30 ° C for 6 hours, washed with a large amount of distilled water until neutral, and ended the reaction. The amount of epoxy groups on the carrier was detected by the sodium thiosulfate method, and it was measured that there were 45 μmol of epoxy groups per gram of carrier.

[0063] (2) Bonded aspartic acid: take 100 mL of the cellulose microspheres obtained by the reaction in step (1), rinse them with a large amount of distilled water, drain them and add them to a 1000 mL round bottom flask, add 500 mL of 0.5 mol / L The aspartic acid solution (adjusted to pH 11 with sodium carbonate) was placed in a constant temperatu...

Embodiment 3

[0075] 1. Preparation of active carrier

[0076](1) Epichlorohydrin activation: Take 100mL of agarose gel microspheres (Sepharose 4FF), wash them with distilled water, drain them, add them to a 1000mL round bottom flask, and add 150mL of 2mol / L sodium hydroxide aqueous solution , 0.3 g of sodium borohydride, 100 mL of epichlorohydrin, placed in a constant temperature shaker, reacted at 20 ° C for 8 hours, rinsed with a large amount of distilled water until neutral, and ended the reaction. The amount of epoxy groups on the carrier was detected by the sodium thiosulfate method, and it was measured that there were 35 μmol of epoxy groups per gram of the carrier.

[0077] (2) Bonded aspartic acid: Take 100 mL of the agarose gel microspheres obtained by the reaction in step (1), rinse with a large amount of distilled water, drain and add to a 1000 mL round bottom flask, add 500 mL of 0.2 mol / L of aspartic acid solution (adjusted to pH 10 with sodium carbonate), placed in a consta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com