Chemical slurry squeezing filtration system

A technology of extrusion filtration and pressurization filter, which is applied in the direction of filtration circuit, filtration separation, chemical instruments and methods, etc. It can solve the problems of inability to adjust in time, low degree of automatic control, single type of chemical slurry, etc., and achieve reduction Inaccurate accuracy, prolonging gravity separation time, and reducing efficiency waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] 本发明的实施例参考 Figure 1-6 shown.

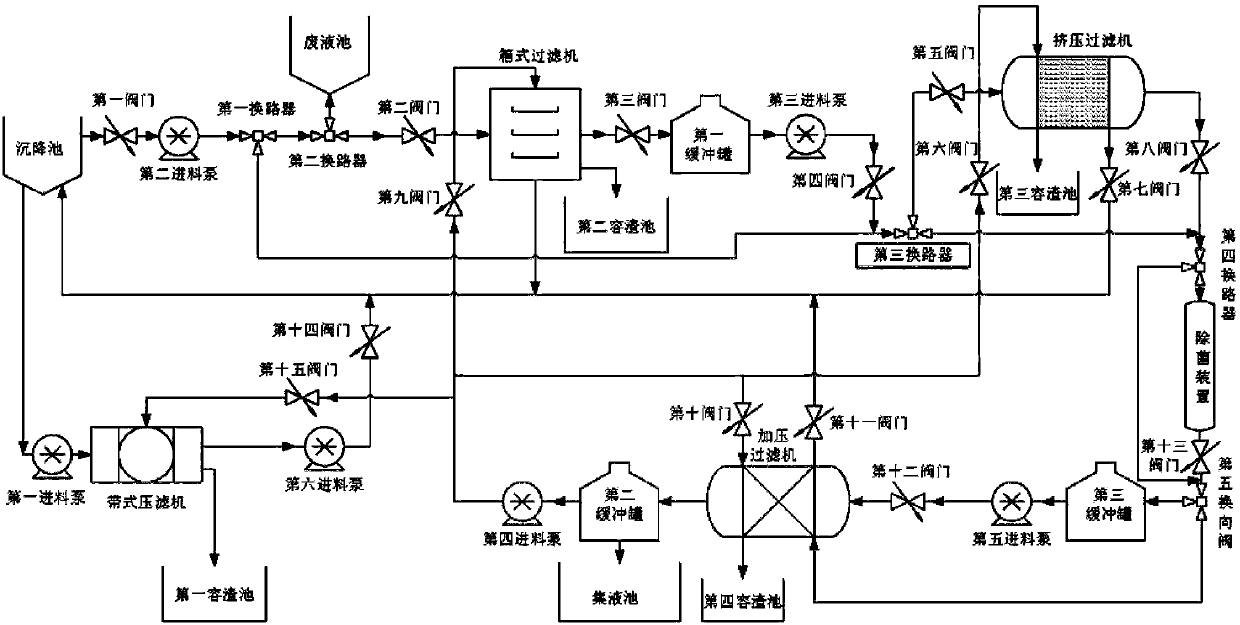

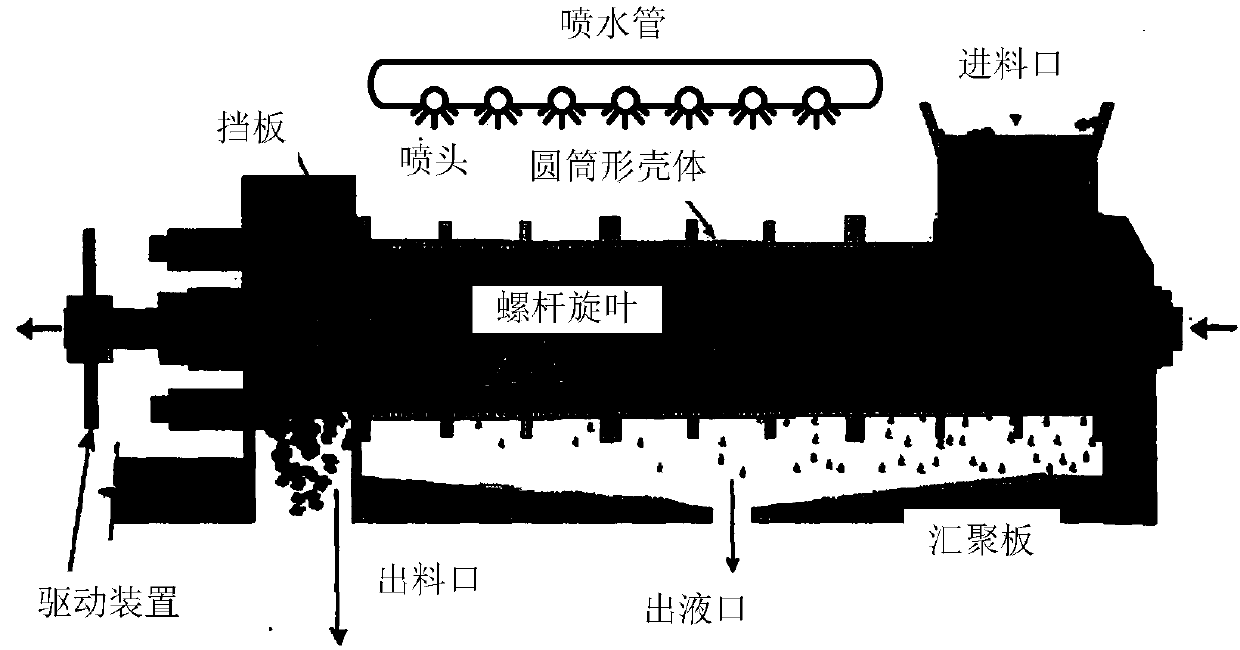

[0025] 一种化工浆料的挤压过滤系统,其包括1个带式压滤机、1个箱式过滤机、1个加压过滤机、1个挤压过滤机、1个除菌装置、1个沉降池、1个废液池、1个集液池、4个容渣池、3个缓冲罐、6个进料泵、5个换路器以及15个阀门,其特征在于:沉降池容纳化工浆料,沉降后的化工浆料通过沉降池底部在第一进料泵的作用下进入带式压滤机,带式压滤机将压滤后的化工物料放入第一容渣池,产生的化工滤液通过第六进料泵以及第十四阀门进入回收主管线返回沉降池,沉降池上部有化工滤液出口,化工滤液通过第一阀门通过第二进料泵进入第一换路器,调节第一换路器,使化工滤液进入第二换路器或者进入第三换路器,调节第二换路器,使化工滤液进入废液池或者进入第二阀门,化工滤液通过第二阀门后,进入箱式过滤机,箱式过滤机下部的化工滤液进入回收主管线返回沉降池,箱式过滤机将过滤后的化工物料放入第二容渣池,箱式过滤机上部的化工滤液经过第三阀门进入第一缓冲罐,缓冲后经过第三进料泵的带动下通过第四阀门进入第三换路器,调节第三换路器,化工滤液进入第五阀门或者第四换路器,化工滤液通过第五阀门后进入挤压过滤机,挤压过滤机下部的化工滤液经过第七阀门进入回收主管线返回沉降池,挤压过滤机将过滤后的化工物料放入第三容渣池,上部的化工滤液通过第八阀门进入第四换向器,调节第四换向器,化工滤液进入除菌装置或者第五换向器,除菌装置底部的化工滤液经过除菌后通过第十三阀门进入第五换向器,调节第五换向器,化工滤液进入第三缓冲罐或者加压过滤机,第三缓冲罐的化工滤液通过第五进料泵以及第十二阀门进入加压过滤机,加压过滤机将过滤后的化工物料放入第四容渣池,加压过滤机底部的化工滤液通过第十一阀门进入回收主管线返回沉降池,加压过滤机上部的化工滤液进入第二缓冲罐,第二缓冲罐内的液体为可重复使用的化工液体,一部分化工液体通过第二缓冲罐底部进入集液池,一部分化工液体作为冲洗液通过第四进料泵分别经过第九阀门、第十阀门、第六阀门以及第十五阀...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com