Device for Adsorption and Separation of Uranium in Radioactive Wastewater by Graphene Oxide Dispersion

A technology for graphene dispersion liquid and radioactive wastewater, applied in radioactive purification, nuclear engineering, etc., can solve the problems of reducing the dispersion of graphene oxide, complex synthesis process, difficult large-scale application, etc., to achieve recyclable utilization, broad Application prospects and the effect of reducing input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

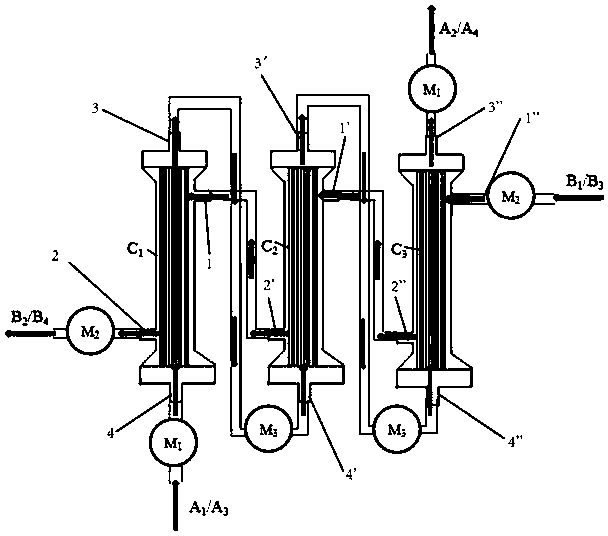

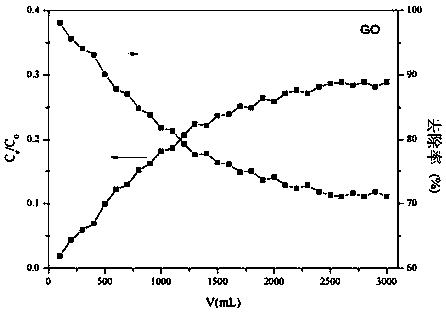

Embodiment 1

[0041] Prepare 1.0 g / L graphene oxide (GO) dispersion and 50 mg / L uranium (VI) solution respectively, and adjust their pH to 6. Start the second power pump M 2 1.0g / L GO dispersion B 1 Enter three hydrophilic pp membrane ultrafiltration columns from top to bottom until full, and from the second power pump M 2 Output uranium-loaded graphene oxide dispersion B 2 , then run at a flow rate ν=0.5 mL / min. Then start the first power pump M 1 and the third power pump M 3 , at a flow rate ν=4.0 mL / min, 50 mg / L uranium ((VI) solution A 1 Input from bottom to top into three hydrophilic pp membrane ultrafiltration columns, and then output purification solution A from the first power pump 2 , while collecting from the second power pump M 2 Output GO dispersion B loaded with uranium 2 . 100 mL of purification solution A per output 2 Take it out and measure uranium (VI) solution A 1 Concentration C 0 and purification solution A 2 Concentration C e . C e / C 0 And the removal ...

Embodiment 2

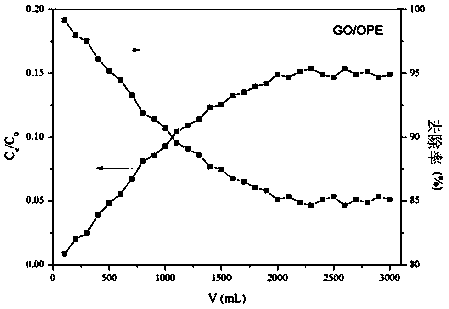

[0044] A 1.0 g / L phosphoethanolamine functionalized graphene oxide (GO / OPE) dispersion and a 50 mg / L uranium(VI) solution were prepared respectively, and their pH was adjusted to 6. Start the second power pump M 2 1.0 g / L GO / OPE dispersion B 1 Enter three hydrophilic pp membrane ultrafiltration columns from top to bottom until full, and from the second power pump M 2 Output GO / OPE dispersion B loaded with uranium(VI) 2 , then run at a flow rate ν=0.5 mL / min. Then start the first power pump M 1 and the third power pump M 3 , at a flow rate ν=4.0mL / min, 50 mg / L uranium (VI) solution A 1 Input from bottom to top into three hydrophilic pp membrane ultrafiltration columns, and then output purification solution A from the first power pump 2 , while collecting from the second power pump M 2 Output GO / OPE dispersion B loaded with uranium(VI) 2 . 100 mL of purification solution A per output 2 Take it out and measure uranium (VI) solution A 1 Concentration C 0 and purificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com