PVC calendered ground mat production system

A production system and floor mat technology, which is applied to flat products, household appliances, and other household appliances, can solve the problems of slow transmission speed, low work efficiency, and debris, and achieve the goal of improving work efficiency and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

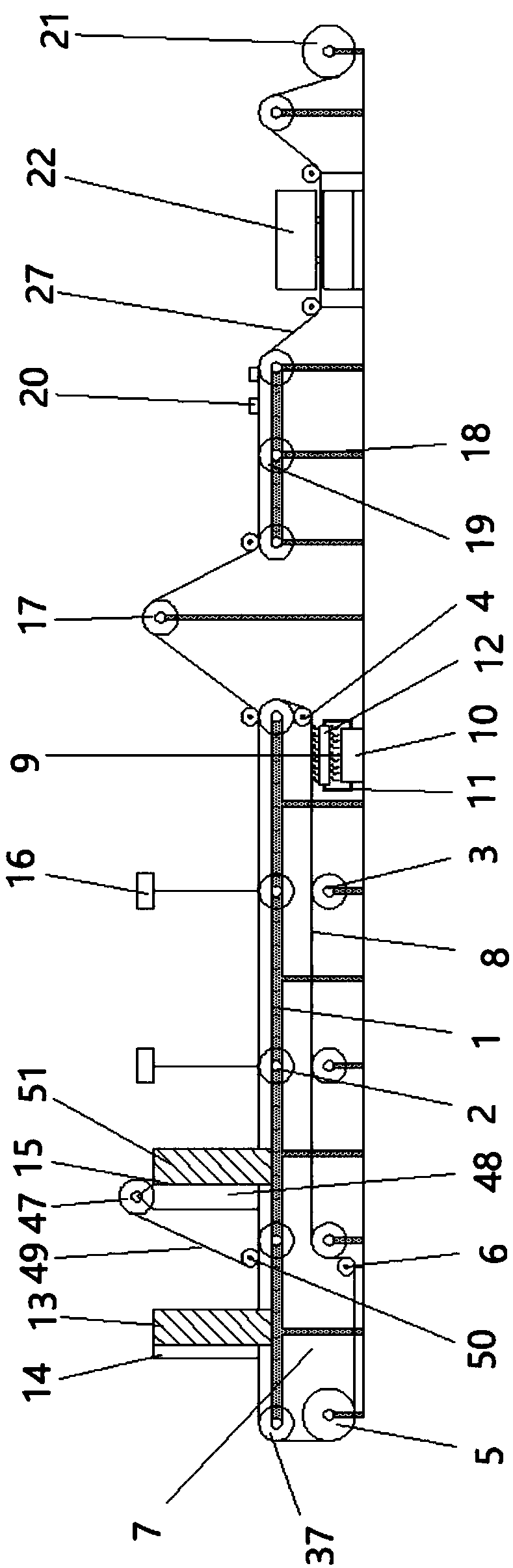

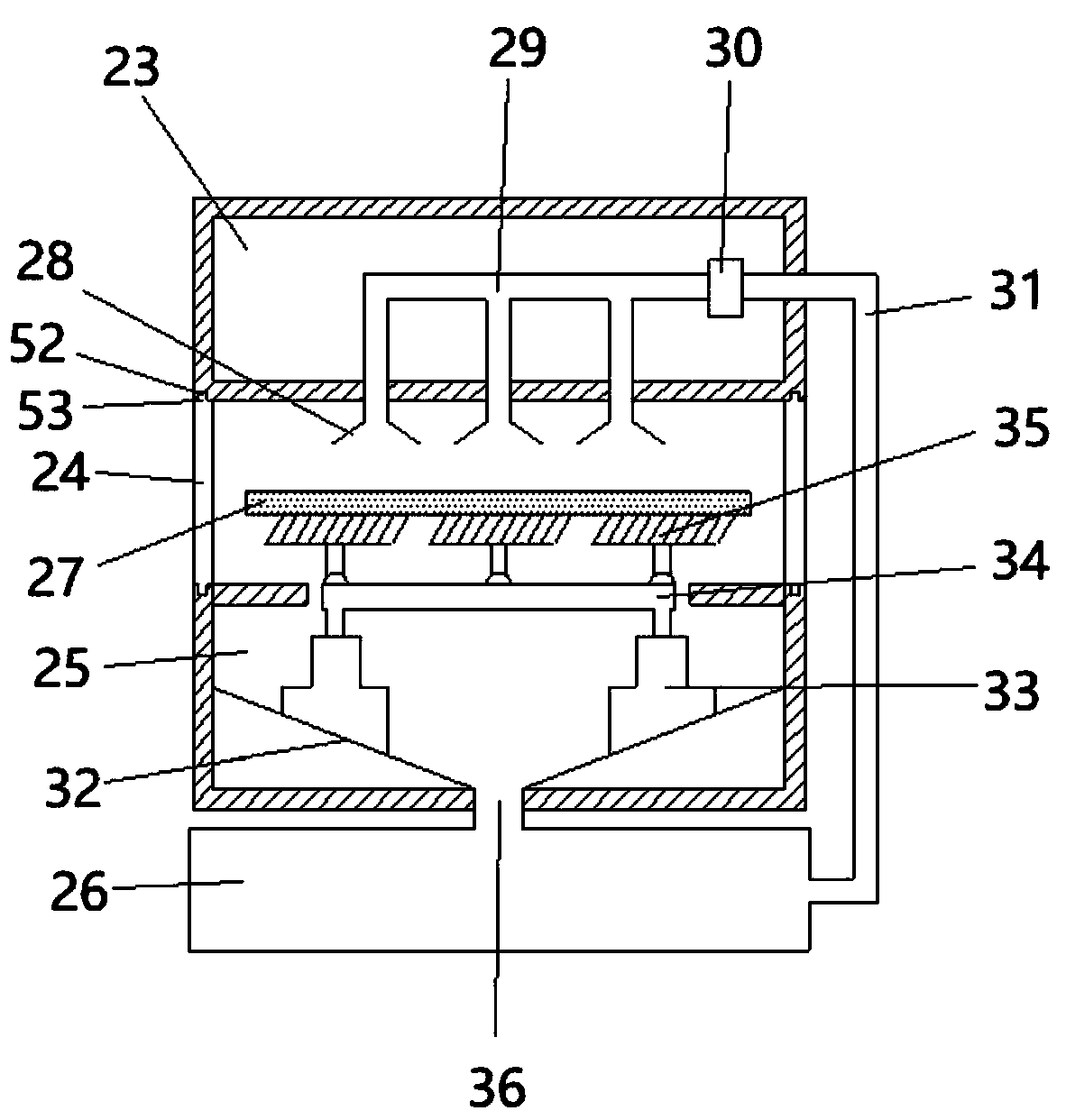

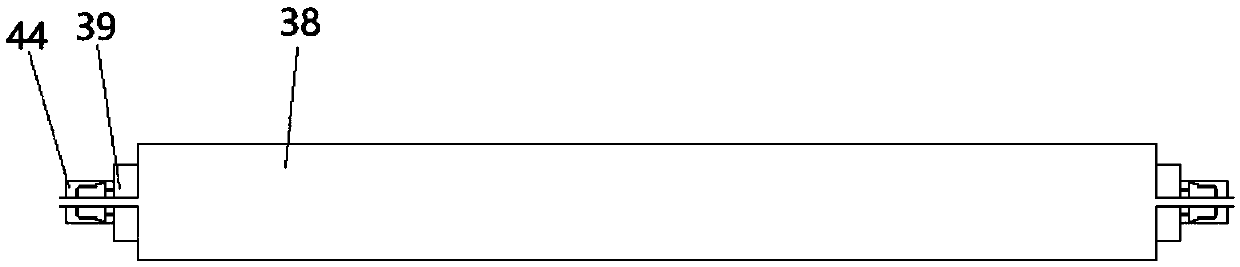

[0017] Embodiment: PVC calendering floor mat production system, structure such as Figures 1 to 5 As shown, the first frame 1 is included, the first frame 1 is provided with a first transmission roller layer 2, the first transmission roller layer 2 is provided with a second transmission roller layer 3, the first transmission roller layer 2 and the second transmission roller layer A first transition roller 4 is arranged between the transmission roller layers 3, a third transmission roller 5 is also provided below the first transmission roller layer 2, and a second transition roller is arranged between the third transmission roller 5 and the second transmission roller layer 3 6. The first transmission roller layer 2, the second transmission roller layer 3 and the third transmission roller 5 cooperate to form a roller circuit 7, and the circulation bottom cloth layer 8 is arranged on the roller circuit 7, and the bottom cloth layer is provided under the circulation bottom cloth la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com