Propulsion-type lawn mowing device

A mowing device and propulsive technology, which is applied in the direction of cutters, harvesters, agricultural machinery and implements, etc., can solve the problems of limited application range, different pruning sizes, laborious use, etc., and achieve wide application range, neat and beautiful pruning , the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

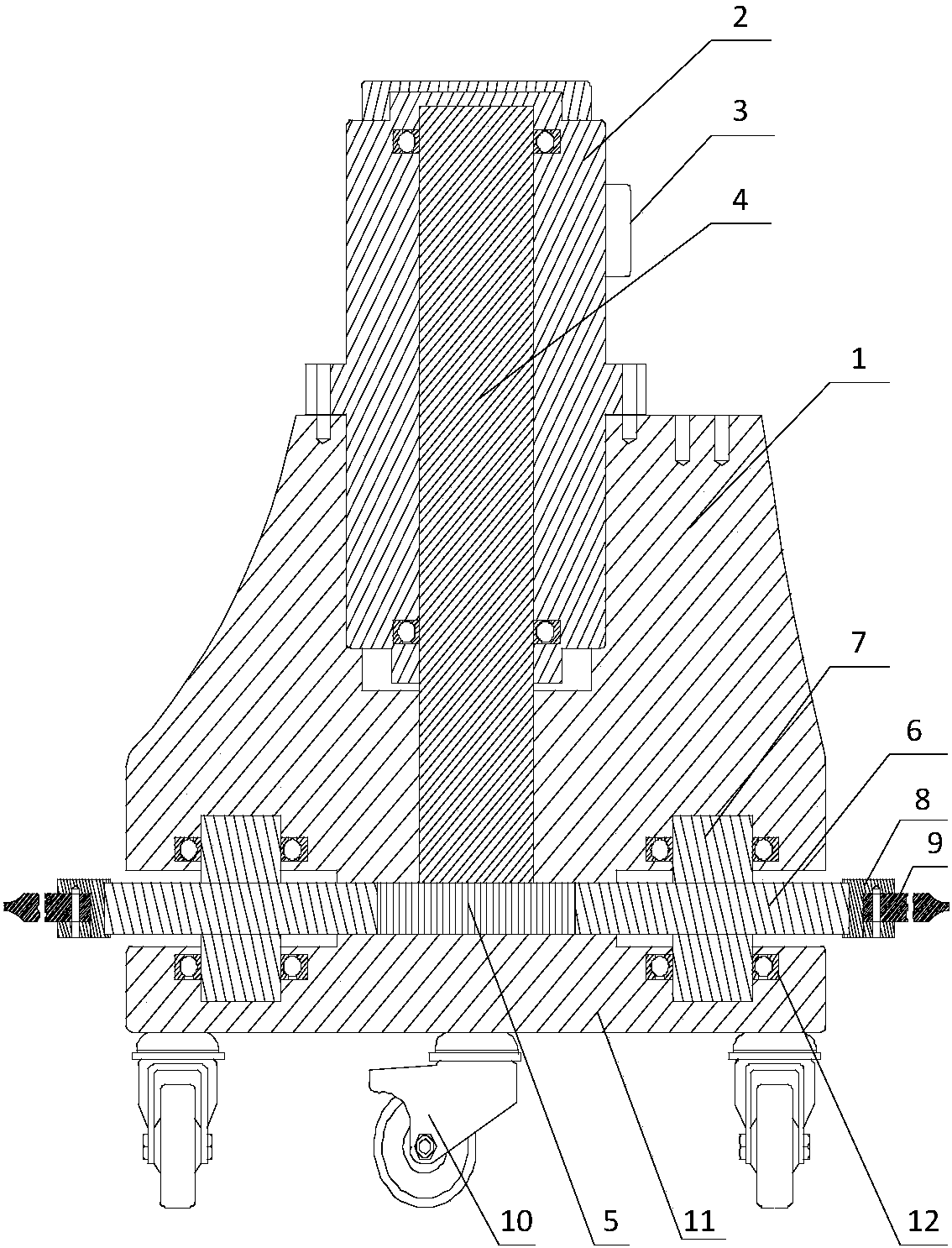

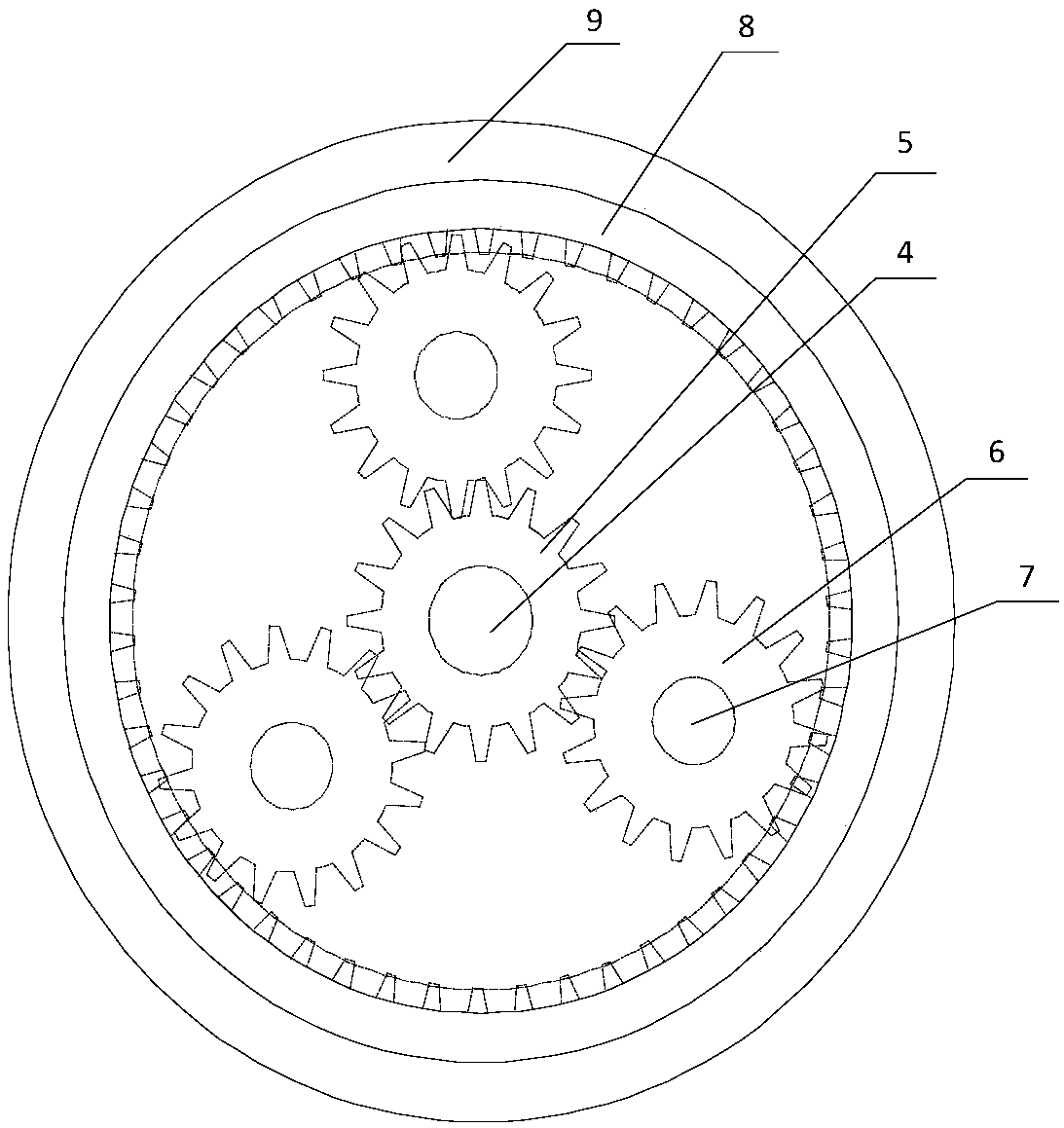

[0024] Such as Figure 1 to Figure 3 As shown, a push-type lawn mowing device includes a cutting motor 2, a junction box 3 arranged on the edge of the outer wall of the cutting motor 2 housing, a motor shaft 4 arranged in the cutting motor 2, connected with the cutting motor 2 housing The cutting propulsion base 1, the motor gear 5 arranged at one end of the motor shaft 4, the lower bottom plate 11 arranged at the bottom of the cutting propulsion base 1, the three drive gears 6 meshing with the motor gear 5, coaxial with the drive gear 6 Center, integrally formed and the upper and lower ends respectively penetrate the support bearing 7 in the cutting propulsion base 1 and the lower bottom plate 11, sleeved on the end of the support bearing 7, the rolling bearing 12 for providing rolling friction, meshed in the inner part of the drive gear 6 The toothed disc 8, the cutting blade 9 fixed on the inner toothed disc 8 and in the shape of a ring, and the four universal wheels 10 arr...

Embodiment 2

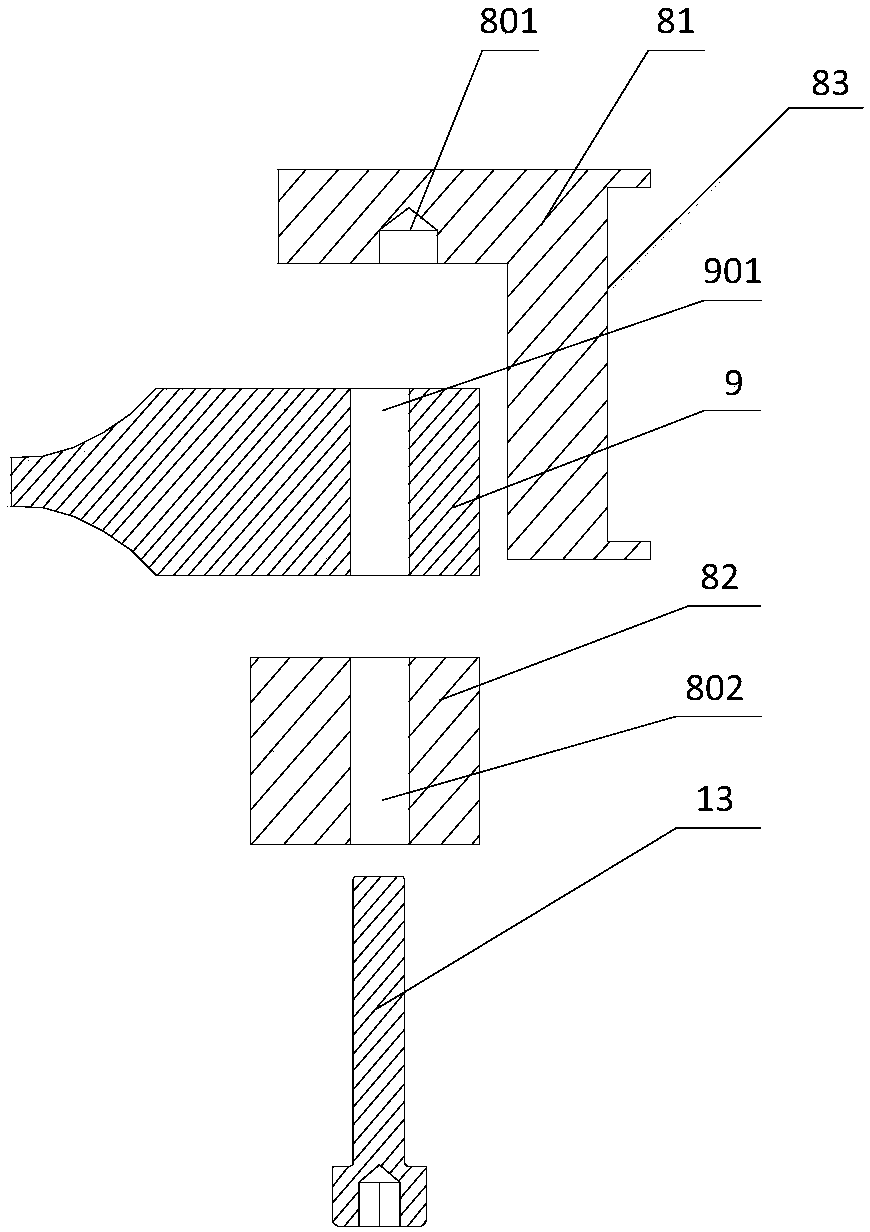

[0027] Such as Figure 4 As shown, other parts of its mowing device are all the same, only the difference between the inner toothed disc 8 and the cutting blade 9, wherein the inner toothed disc 8 includes an upper inner toothed disc (81) and an extrusion plate 82, and the upper inner toothed disc 81 The bottom circle is provided with a blind hole 801 for fixing the cutting blade 9, and the extruding plate 82 is L-shaped, and the first through hole 802 matching the blind hole 801 is arranged on the extruding plate 82, and the inner hexagonal bolt 13 is used. The cutting blade 9 is fastened and pressed between the upper inner gear plate 81 and the pressing plate 82, and the cutting blade 9 is in the shape of a ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com