Connector

A technology for connectors and soldering parts, which is applied in the direction of connection, fixed connection, conductive connection, etc., and can solve problems such as assembly errors, inability to perform reflow soldering process steps, and poor soldering effect of connector circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to facilitate a better understanding of the purpose, structure, features, and effects of the present invention, the present invention will now be further described in conjunction with the accompanying drawings and specific embodiments.

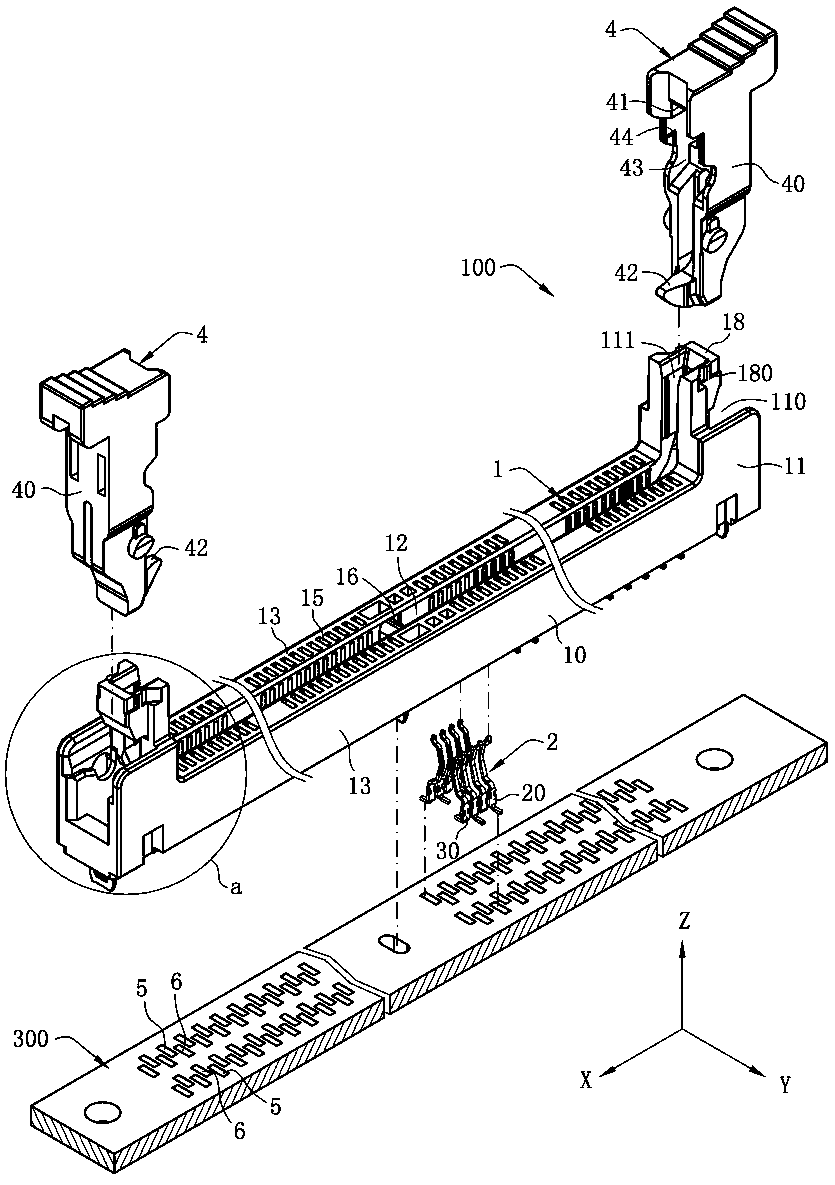

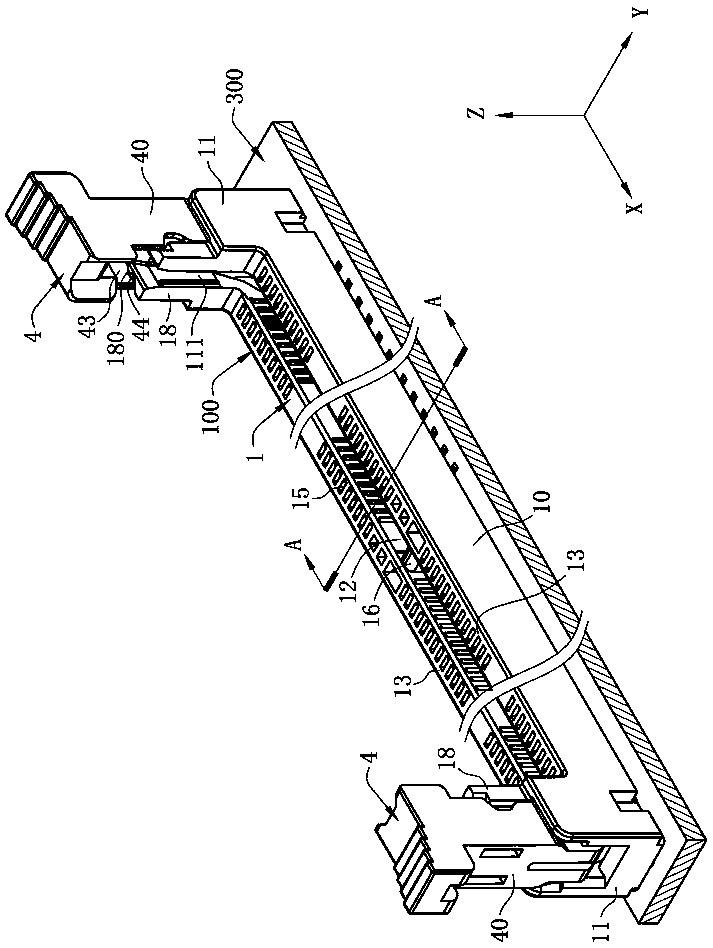

[0041] see figure 1 and Image 6 , is a connector 100 of the present invention, used to electrically connect the electronic card 200 and the circuit board 300, the connector 100 is installed downward on the circuit board 300, and the connector 100 includes an insulating body 1, A plurality of terminals 2 disposed on the insulating body 1 and two ear buckles 4 pivotally connected to the insulating body 1 . The connector 100 defines a longitudinal direction X, a lateral direction Y, and a vertical direction Z, and the three are perpendicular to each other.

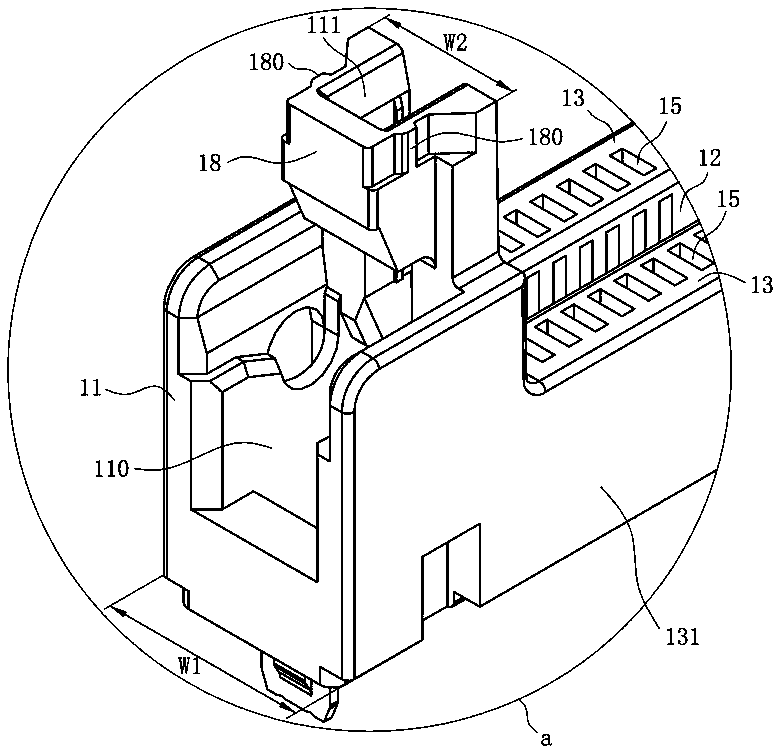

[0042] see figure 1 , figure 2 and Image 6, the bottom surface of the insulating body 1 is set facing the circuit board 300 . The insulating body 1 has a base portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com