Pressurized water nuclear reactor nested component

A nuclear reactor and nested technology, applied in the field of nuclear power, can solve problems such as difficult to eliminate coolant turbulence and turbulent eddy current, unsatisfactory flow distribution effect, and coolant flow attenuation, so as to achieve stable and uniform coolant, simple structure, and low Attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

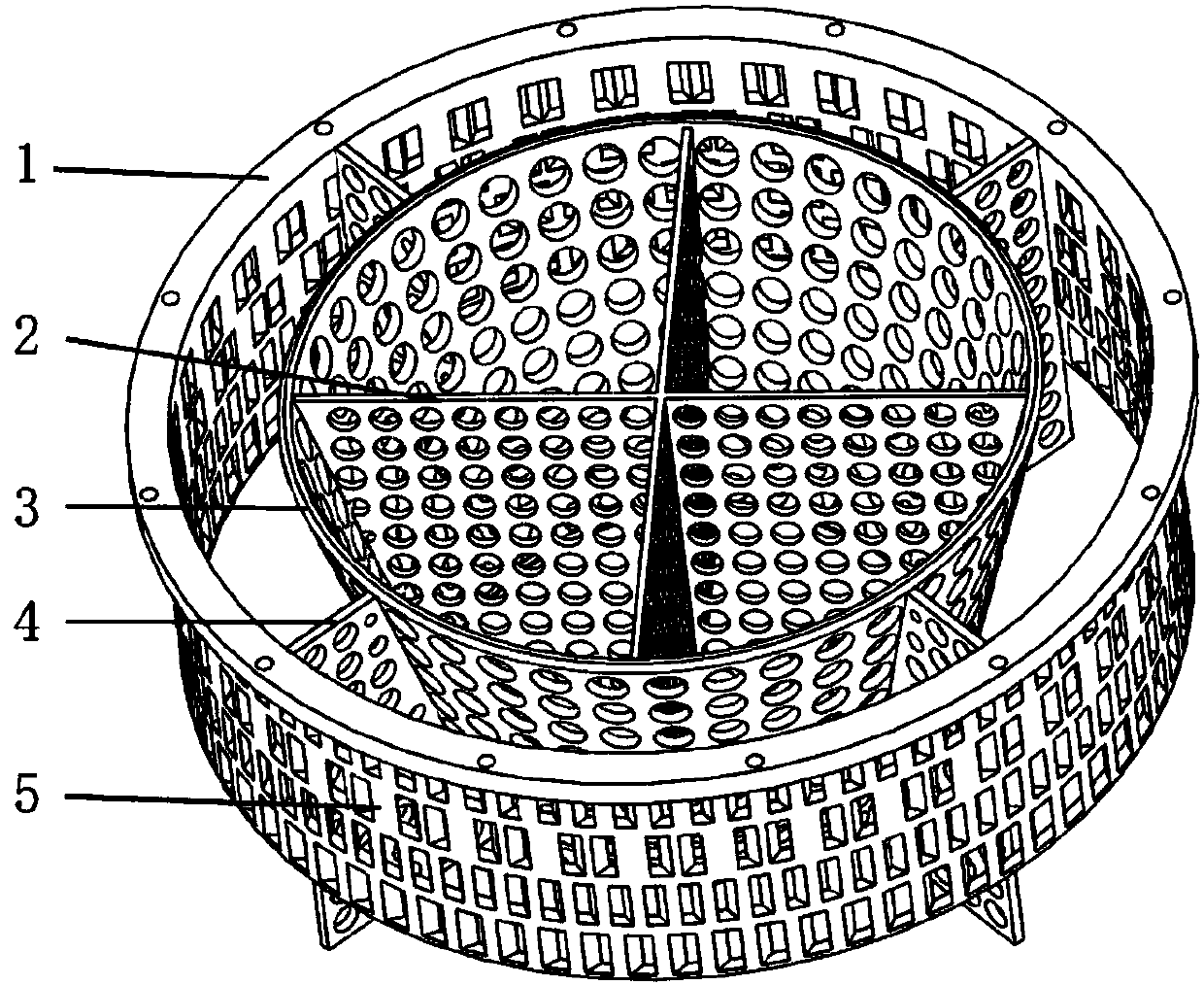

[0034] In this embodiment, the nested components of the pressurized water nuclear reactor are such as figure 1 As shown, it is composed of an inner flow distribution cylinder 3 , an outer flow distribution cylinder 5 , an outer flow distribution plate 4 , an inner flow distribution plate 2 and an outer flange 1 .

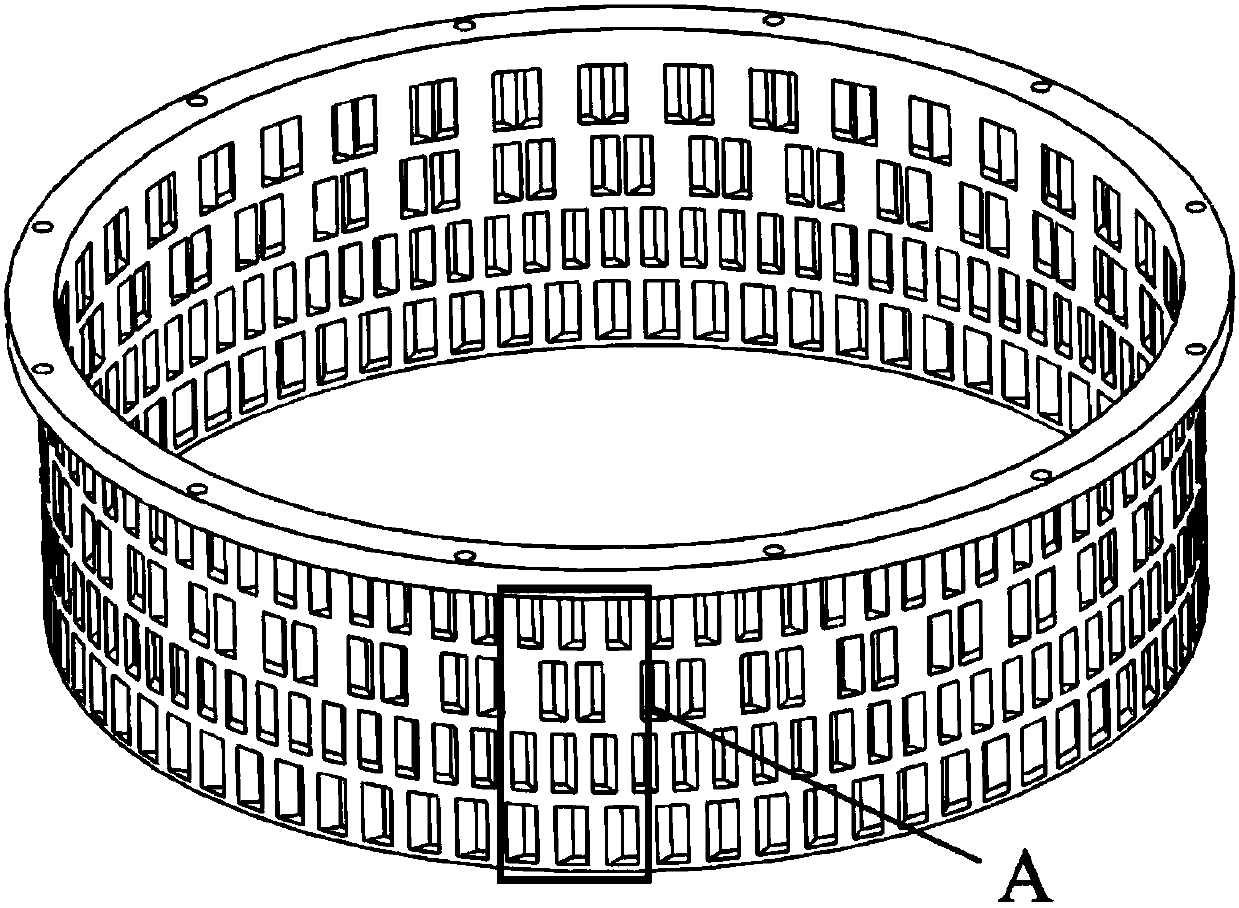

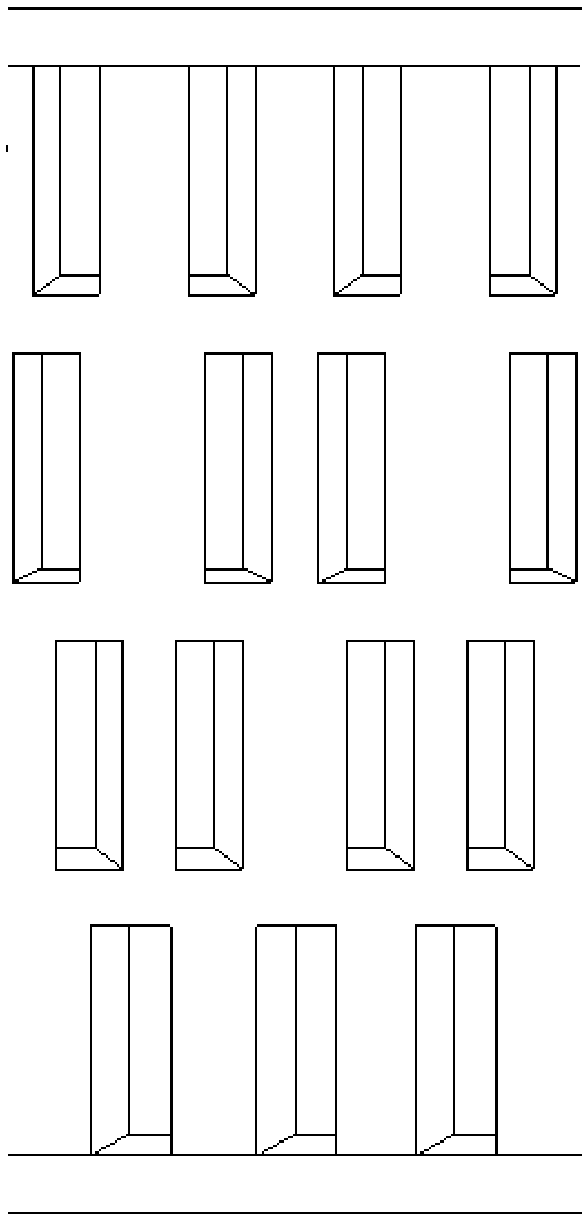

[0035]The outer flow distribution cylinder 5 is as figure 2 As shown, it is a cylinder with openings at both ends, and a plurality of flow holes are arranged on the wall of the cylinder. The flow holes are arranged in a four-layer ring, and the total water flow area of each layer of flow holes increases sequentially from the upper layer to the lower layer; image 3 As shown, the shape of the flow holes of each layer is rectangular. From top to bottom, the opening directions of the adjacent two flow holes of the first layer and the second layer are staggered to form a certain angle, and the opening directions of the flow holes of the third layer and the fourth lay...

Embodiment 2

[0042] In this embodiment, the nested components of the pressurized water nuclear reactor are such as Figure 6 As shown, it is composed of an inner flow distribution cylinder 3 , an outer flow distribution cylinder 5 , an outer flow distribution plate 4 , an inner flow distribution plate 2 and an outer flange 1 .

[0043] The difference from Example 1 is: (1) the inner layer flow distribution cylinder 3 is a cylinder with openings at both ends; (2) the outer layer flow distribution plate 4 and the inner layer flow distribution plate 2 are rectangular plates; (3) The height of the outer layer flow distribution cylinder 5 is the same as that of the inner layer flow distribution cylinder 3, and after combination, the distance between the inner layer flow distribution cylinder 3 and the outer layer flow distribution cylinder 5 is 500 mm.

Embodiment 3

[0045] In this embodiment, the nested components of the pressurized water nuclear reactor are such as Figure 7 As shown, it is composed of an inner flow distribution cylinder 3 , an outer flow distribution cylinder 5 , an outer flow distribution plate 4 , an inner flow distribution plate 2 and an outer flange 1 .

[0046] The difference from Example 1 is: (1) the outer flow distribution cylinder 5 is a truncated conical cylinder with openings at both ends, a large top and a small bottom, and the taper is the same as that of the inner flow distribution cylinder 3; (2) the outer layer The total water flow area of each layer of flow holes of the flow distribution cylinder 5 is the same; (3) the height of the outer layer flow distribution cylinder 5 is the same as the height of the inner layer flow distribution cylinder 3. After combination, the inner layer flow distribution cylinder 3 and the outer layer The distance between the flow distribution cylinders 5 is 600mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com