Temperature and pressure combined measurement system and measurement method

A temperature pressure, measurement system technology, applied in the direction of measuring heat, thermometer, measuring force, etc., can solve the problems of destroying the pressure field structure of the test target, destroying the surface structure, and being easily restricted in installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

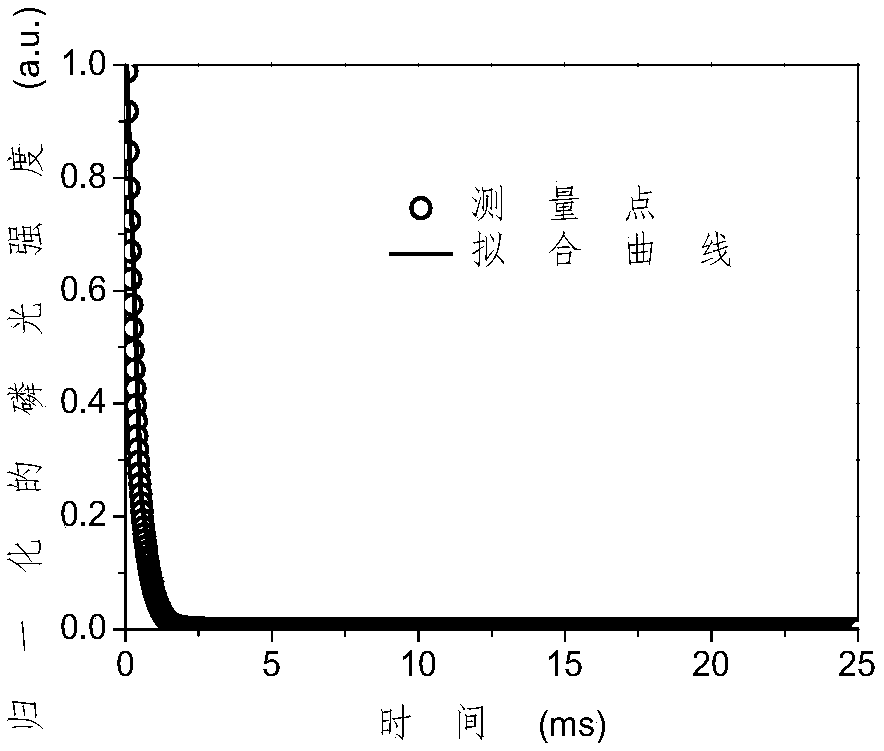

[0053] A temperature and pressure joint measurement system, its structure is as follows figure 1 As shown, it includes a signal transmitter 1, a laser light source 2 electrically connected to the signal transmitter 1, a temperature and pressure probe 4, and a temperature and pressure signal processing unit used in conjunction with the temperature and pressure probe 4. The temperature signal processing unit includes a spectroscope 7. Reflector 8, temperature phosphorescence filter 9, pressure phosphorescence filter 10, temperature photomultiplier tube 11, temperature resistance box 13 connected with temperature photomultiplier tube 11, pressure photomultiplier tube 12, connected with pressure photomultiplier tube 12 A piezoresistive box 14 and an oscilloscope 15 for collecting signals. The surface of the temperature and pressure probe 4 is sprayed with Zr 3 Y 4 o 12 : Eu and MFG mixed phosphor layer 6, and respectively connected with laser light source 2 and beam splitter 7 ...

Embodiment 2

[0080] This embodiment is basically the same as Embodiment 1, except that the wavelength of the laser ultraviolet light source is 380nm, and the power of the light source is 3w. The resistance of the resistance box 6 is set to 300Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com