Intelligent temperature control system and method for calcining furnace kiln

A technology of temperature control system and calciner, which is applied to furnace control devices, furnaces, furnace types, etc., can solve the problems of rough temperature control method, limited energy of workers, and many temperature adjustment points, etc., to facilitate parameter setting and reduce labor. Strength, the effect of easy manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

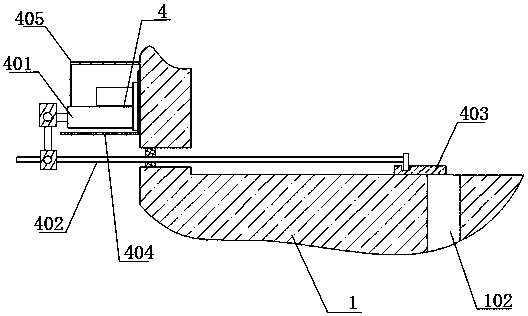

[0027] An intelligent temperature control system for a calciner kiln such as figure 2 , image 3 and Figure 4As shown, it includes multiple groups of calciner tanks 1, temperature control device 2, damper control device 3, lower burner control device 4 and intelligent control terminal. The temperature control device 2 adjusts the calcined charge by controlling the damper control device 3 and lower burner control device 4. The temperature of the tank 1, the temperature control device 2 includes a control unit 201, an antenna 202, a switching power supply module 203 and a manual adjustment device, and a plurality of control units 201 are connected in parallel with 220V AC power supply and uninterruptible power supply 205, 220V AC power supply and uninterruptible power supply 205 It is used to supply power to the temperature control box 2 and the switching power supply module 203. The uninterruptible power supply 205 can reduce the impact of sudden power failure on the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com